A device for detecting and correcting the reed inside the oil suction pipe and closing the mouth of the pipe

A technology of closing device and oil suction pipe, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of reducing production costs, reducing the stoppage of continuous production devices, and achieving good consistency of closing and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

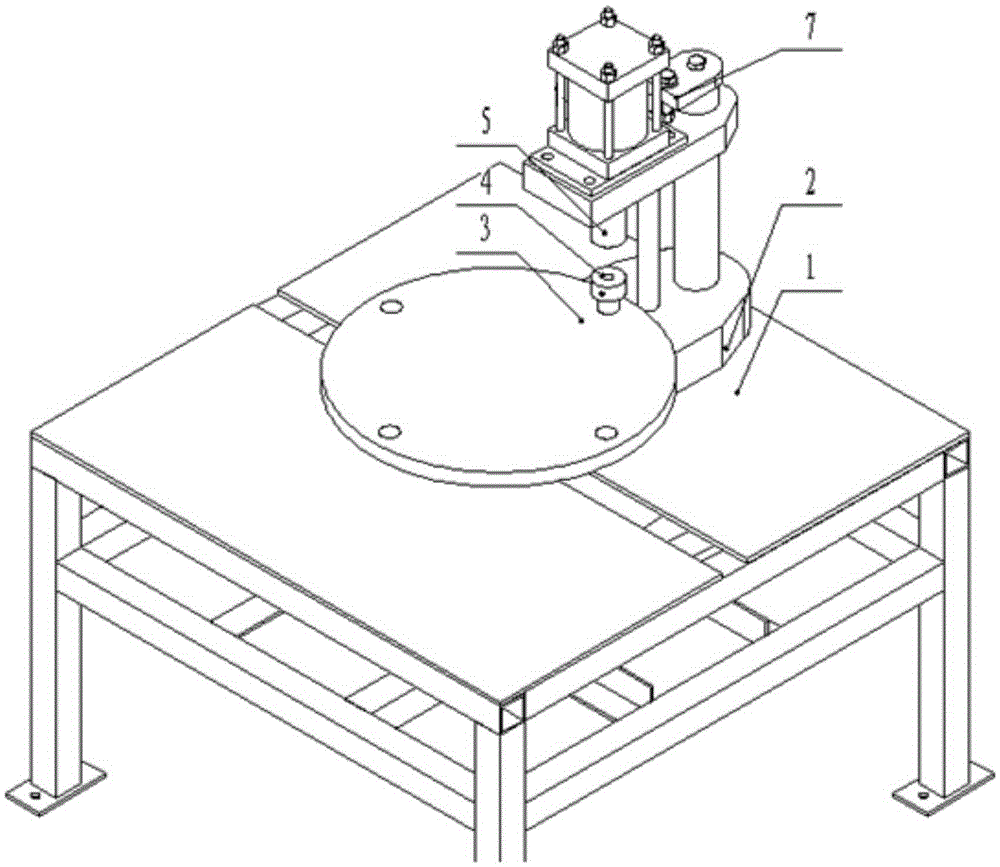

[0040] Example 1 Detection and correction of the reed inside the oil suction pipe and the device for closing the mouth of the pipe

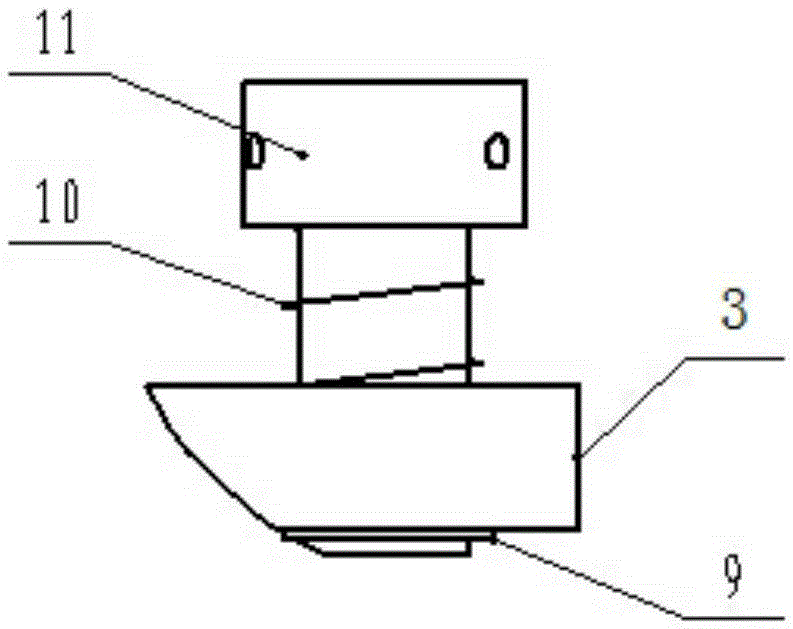

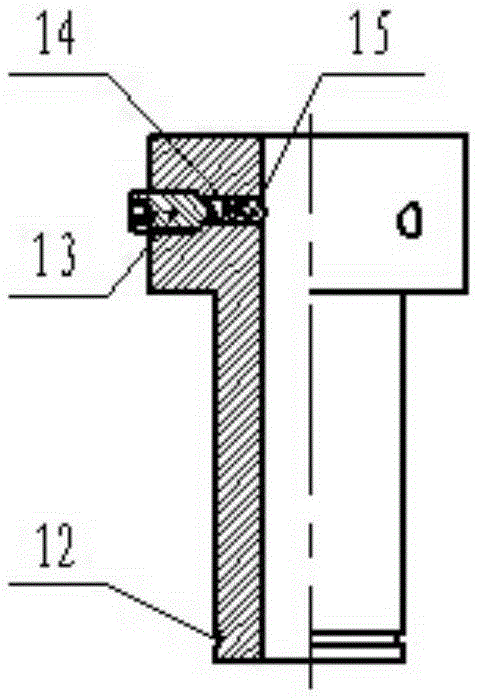

[0041] The internal reed detection and correction of the oil suction pipe provided by this embodiment and the nozzle closing device (see Figure 1-6 ) includes a base 1, a workbench 2, a rotating index plate 3, a fixture 4, a detection closing assembly 5, and a height adjustment assembly 7. The workbench 2 is installed on the upper surface of the base, and the workbench is used to install other parts. The rotary index plate 3 and the height adjustment assembly 7 are directly installed on the workbench. The rotary index plate is a disc-shaped flat cylinder. The fixture 4 is installed on the rotary index plate. The gas-liquid booster cylinder is installed on the height adjustment assembly 7. Above, the detection port assembly 5 is fixed at the end of the piston rod 19 of the gas-liquid booster cylinder.

[0042] The workbench is composed of a moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com