Sequence valve with temp. memory

A technology of temperature memory and sequence valve, applied in the direction of valve details, safety valve, balance valve, etc., can solve the problems of reducing system operating costs, high energy consumption, unfavorable energy saving, etc., achieve good working effect, increase dehumidification capacity, expand The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

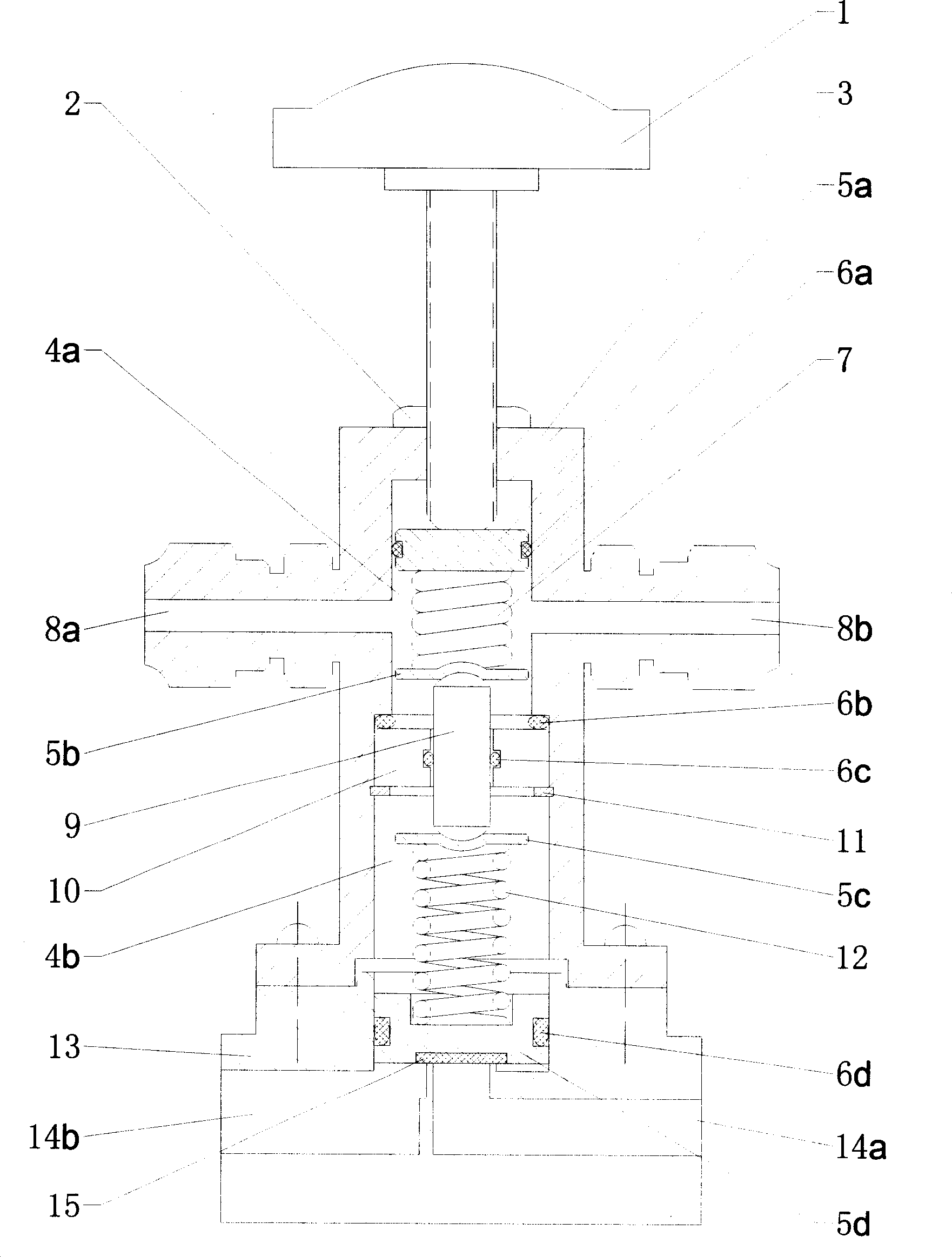

[0009] The structure of the embodiment of the present invention will now be described in conjunction with the accompanying drawings: a sequential valve with temperature memory, as shown in the accompanying drawings, consists of a main body 3, a main body seat 13, a pressure regulating rod 1, transmission plates 5c and 5d, and a compression spring 12. Composed of air inlet 14a and air outlet 14b.

[0010] The main body 3 is seated on the main body seat 13 through fasteners, and a cavity 4 is formed between them. A circlip 11 for holes is embedded in the cavity 4 , and a sealing block 10 is seated on the circlip 11 for holes. Then the sealing block 10 divides the cavity 4 into two independent spaces, upper and lower, of the sampling cavity 4a and the discharge cavity 4b. A transmission rod 9 passes through the sealing block 10 and can slide therein, and its two ends are respectively located in different areas of the sampling cavity 4a and the discharge cavity 4b.

[0011] On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com