Hot air blowing dryer capable of circularly heating

A technology of circulating heating and drying machine, applied in the direction of drying machine, drying, heating device, etc., can solve the problems of poor air supply effect, inconvenient dehumidification, and inability to realize circulating air supply by wind force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

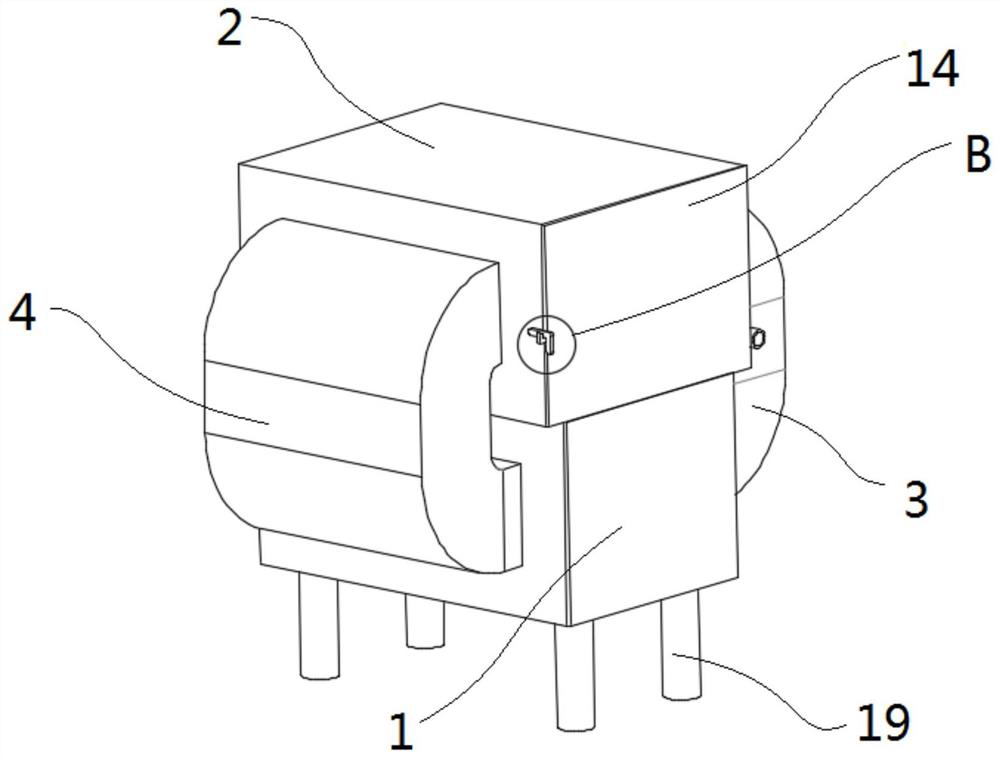

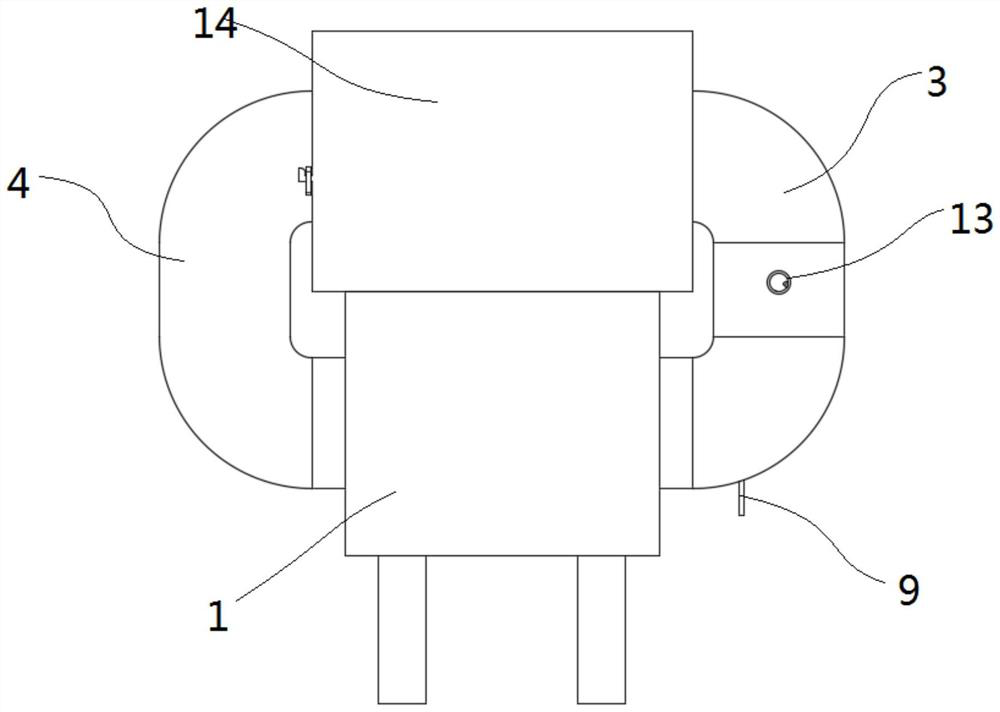

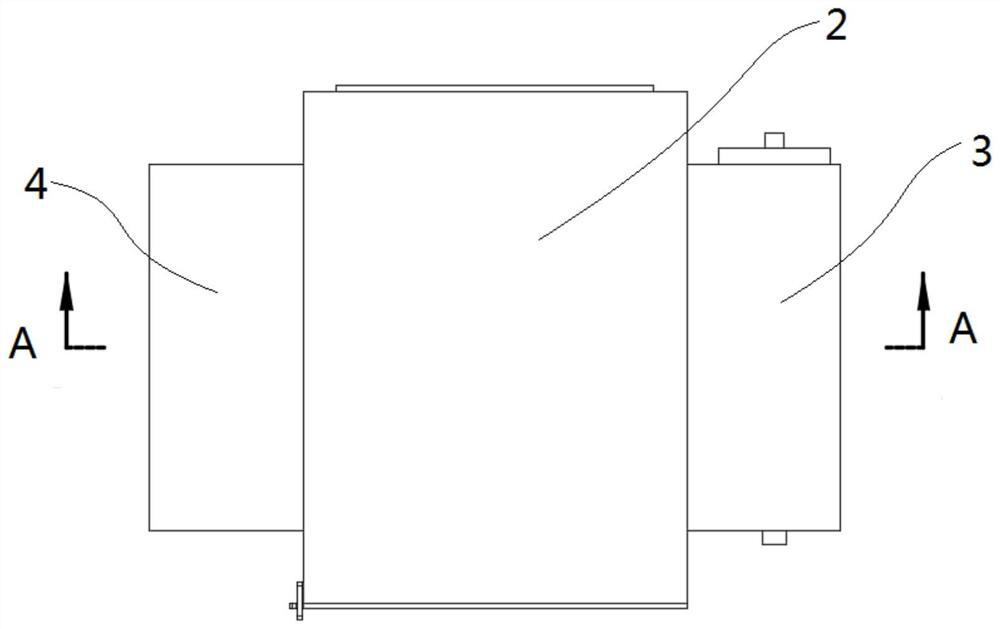

[0033] Please refer to Figure 1-5 As shown, the present invention is a hot air blowing dryer for circulating heating, including a lower casing 1, an upper casing 2, a first air duct 3 and a second air duct 4 oppositely arranged on the side of the lower housing 1 , the dehumidifying assembly arranged in the first air duct 3, and the second air duct 4 is provided with a constant flow fan 12;

[0034] The upper casing 2 is located directly above the lower casing 1, and the upper casing 2 and the side of the lower casing 1 are provided with air duct openings. The first air duct 3 and the second air duct 4 have a C-shaped structure, and the first air duct The upper and lower ends of the channel 3 and the second air channel 4 are connected through the air channel opening;

[0035] The dehumidifying assembly includes water tanks 5 relatively arranged on both sides of the first air channel 3. The interior of the water tanks 5 is hollow, and a number of condensation water pipes 6 are...

Embodiment 2

[0046] Such as Figure 9 as shown, Figure 9 It is a schematic diagram of the overall structure of the drying box in Embodiment 2 of the present invention. The difference from Embodiment 1 is that the bottom and side walls of the drying box 16 are provided with a number of strip-shaped through holes in an array. This embodiment is mainly used for drying. Dry the material with a slightly larger volume, and the material will not fall off from the strip-shaped through-hole. The setting of the strip-shaped through-hole increases the direct contact area between the material and the hot air, which facilitates the evaporation of moisture in the material and facilitates the drying of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com