A heat pump drying system with dehumidification and waste heat utilization

A heat pump drying and hot-end technology, which is applied to machines that use waste heat, drying, heat pumps, etc., can solve the problems of reducing energy loss, excessive equipment, wasting waste heat, etc., to improve recycling rate, strengthen dehumidification effect, simplify structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

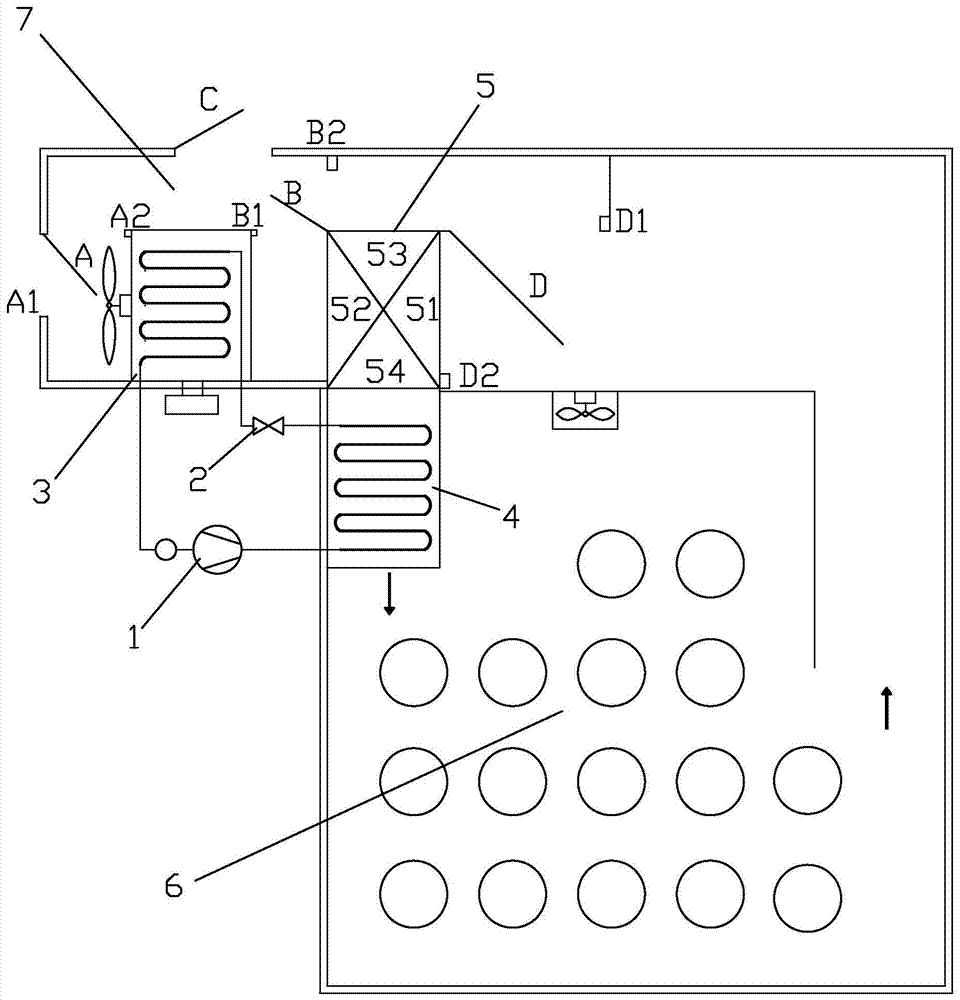

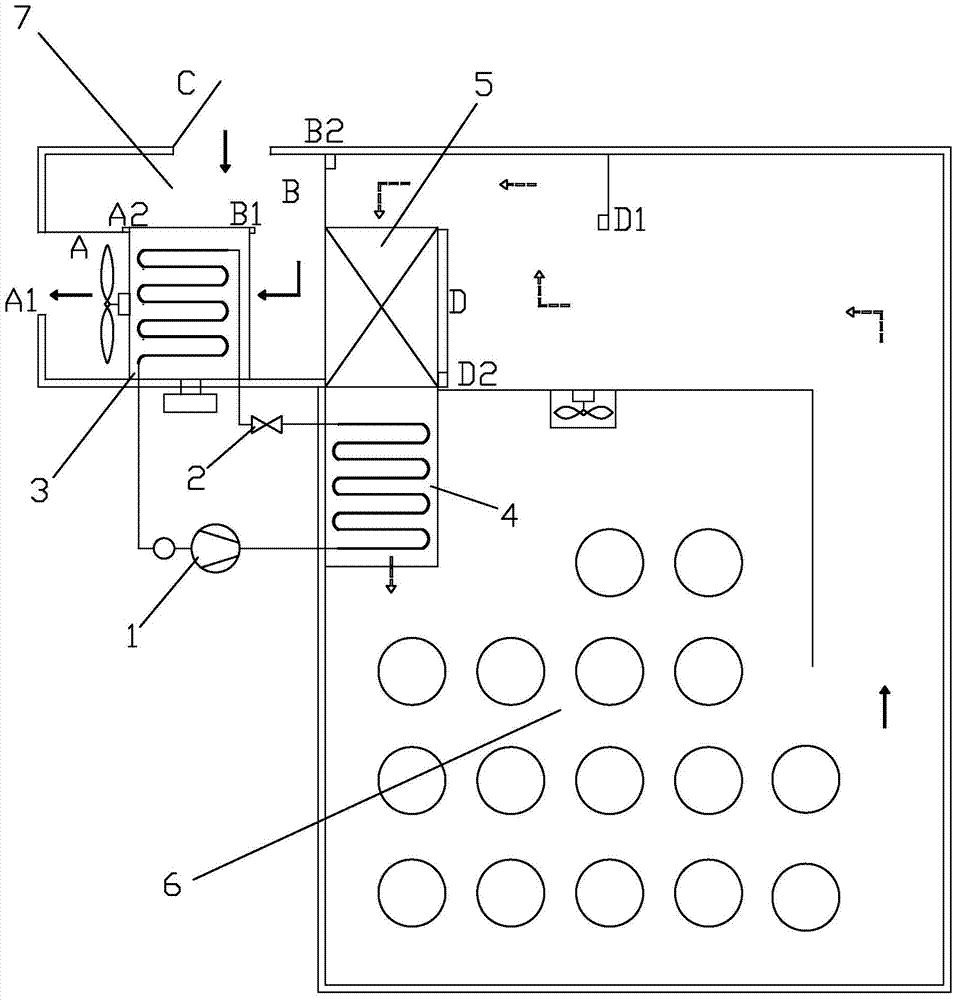

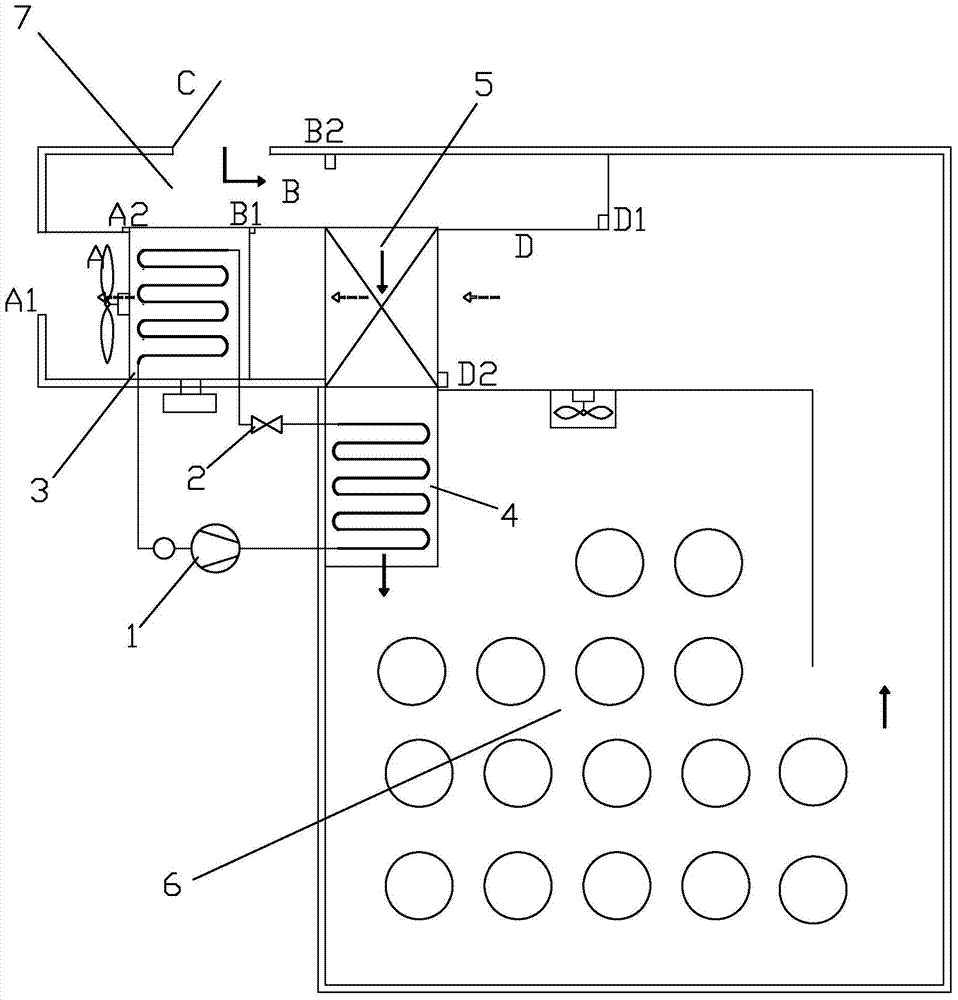

[0017] refer to figure 1 , a heat pump drying system with dehumidification and waste heat utilization of the present invention, and a switchable air duct, including a compressor 1, a condenser 4, an evaporator 3, a throttling element 2, and an enhanced dehumidification effect and heat recovery The effect of the heat exchanger 5, the condenser 4 is installed in the drying room 6, the compressor 1, the throttling element 2 and the evaporator 3 partition wall are installed outdoors or other locations and the refrigerant pipes are connected to the condenser 4 connected, the evaporator 3 and the heat exchanger 5 are installed in a controllable air duct 7, the heat exchanger 5 is located at the central position of the air duct 7, and the air duct 7 is provided with at least two controllable air inlet and outlet ports for heat exchange The air inlet 51 of the first heat exchange end of the device 5 is controllably communicated with the drying room 6 through the air duct 7, and the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com