System closed loop type sludge dehumidifying and drying system

A drying system, closed-loop technology, applied in the field of drying systems, can solve the problems of condenser heat release performance limitation and heat loss, achieve stable and reliable closed-loop operation, and improve the effect of harsh working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

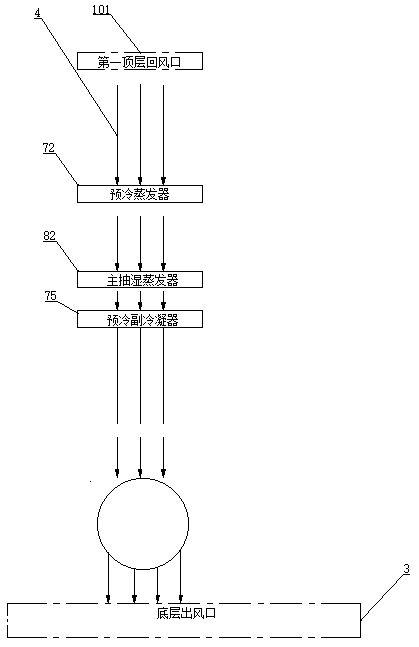

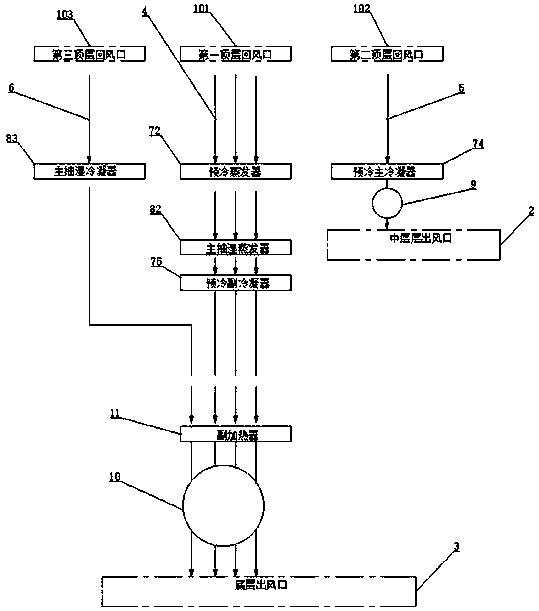

[0038] Such as figure 2 As shown, the system closed-loop sludge dehumidification and drying system of the present invention includes a box body, and the box body is divided into a sludge drying zone a and a dehumidification heating zone b by a partition, and the dehumidification heating zone b has at least one first top layer loop The tuyere 101, at least one second top-floor air return port 102 and at least one third top-floor air return port 103, the first top-floor air return port 101, the second top-floor air return port 102, and the third top-floor air return port 103 are all opposite to the sludge drying zone a The cooler top is connected.

[0039] The dehumidification heating zone also has at least one middle air outlet 2 and at least one bottom air outlet 3, the middle air outlet 2 communicates with the middle of the sludge drying zone a, and the bottom air outlet 3 communicates with the bottom of the sludge drying zone a;

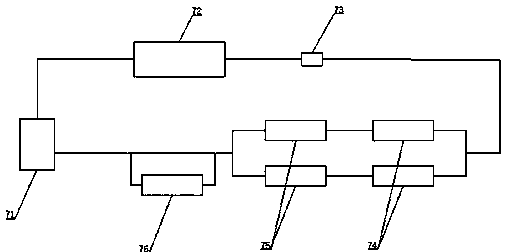

[0040] In the present invention, the dehumid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com