A pull-and-press device for corrosion resistance and shear resistance testing of anchor rods

An anti-corrosion and anti-shear force technology, applied in the direction of applying stable shear force to test material strength, weather resistance/light resistance/corrosion resistance, measuring devices, etc., can solve the problem of single force direction, variable force direction, No problems such as simulating the geological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

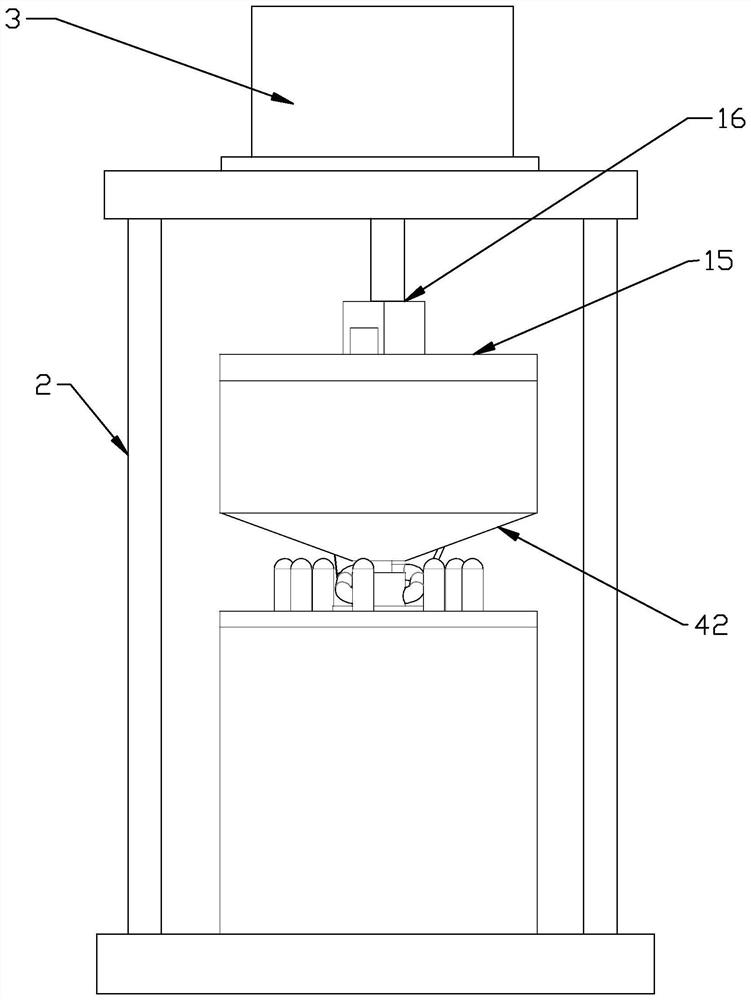

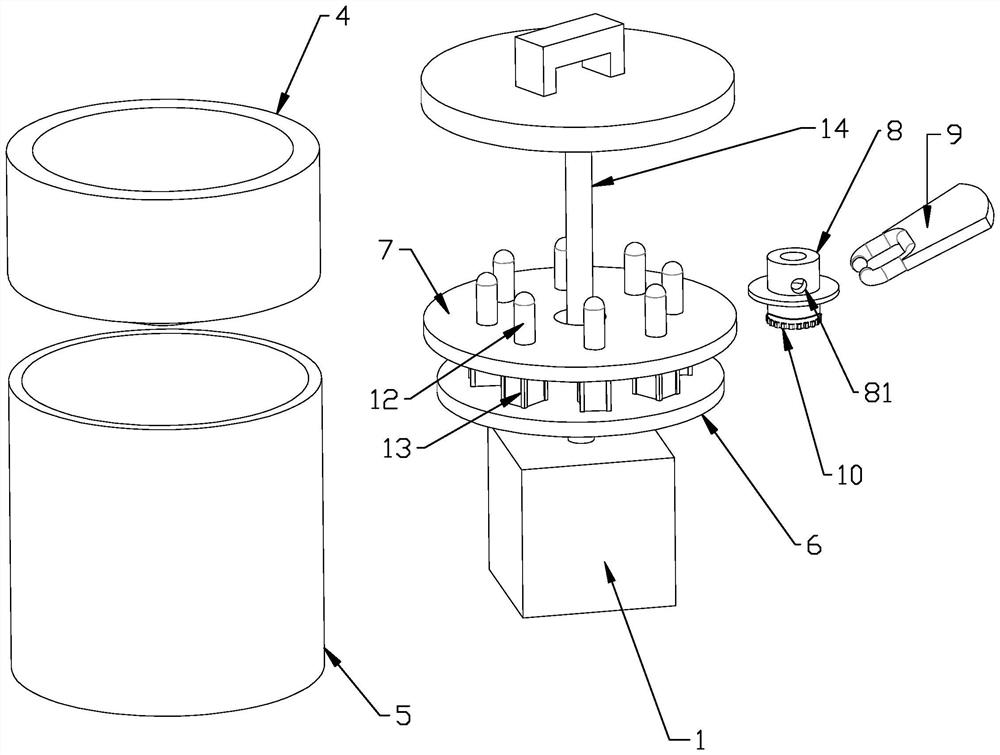

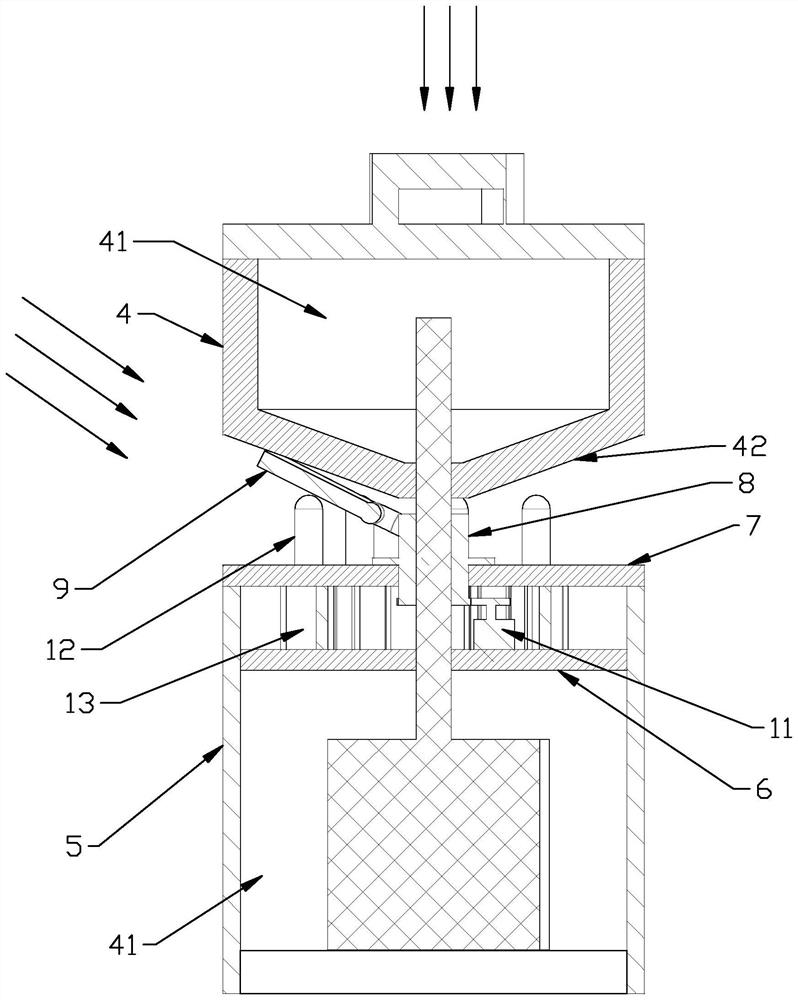

[0020] like Figure 1-4 As shown in the figure, a pulling and pressing equipment for the anti-corrosion and shearing force test of the anchor rod, including the anchoring test piece 1, the frame 2, the hydraulic press 3, the PLC controller and the shearing force module, the shearing force module It includes an upper pressing cylinder 4, a shear force changing device and a lower loading cylinder 5. The upper pressing cylinder 4 and the lower loading cylinder 5 are coaxially arranged up and down on the frame 2, and are provided with a solid filling cavity 41. 4. A truncated cone 42 is provided toward the bottom end of the lower loading cylinder 5. The truncated cone 42 is provided with a steel bar 14 along the center which penetrates to the solid filling cavity 41. The anchoring test piece 1 is arranged in the solid filling cavity of the lower loading cylinder 5. 41, the steel bar 14 of the anchoring specimen 1 extends into the upper pressure cylinder 4 through the hole of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com