Line changing track length compensator and installation technology and working process thereof

A technology of length compensation and compensator, which is applied in the direction of track, track laying, track maintenance, etc., to achieve the effect of reducing vibration, low cost, and meeting the requirements of frequent track changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

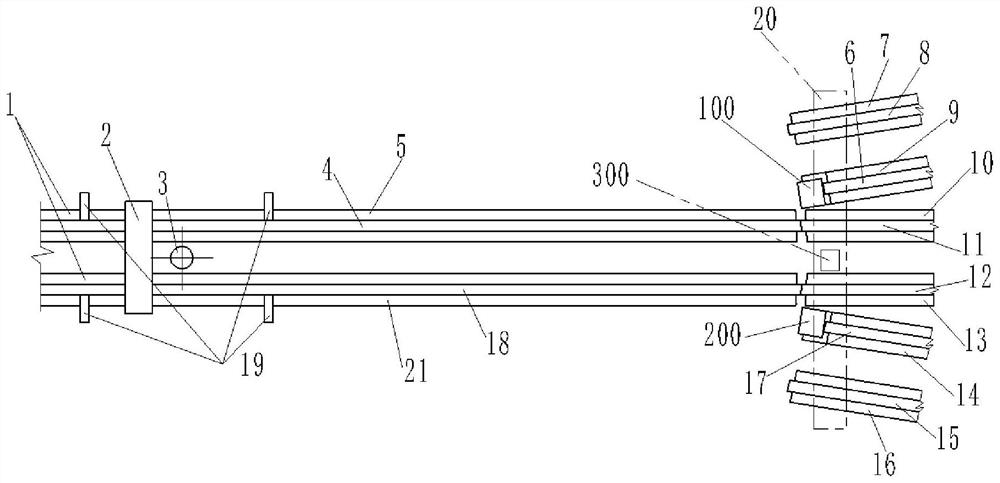

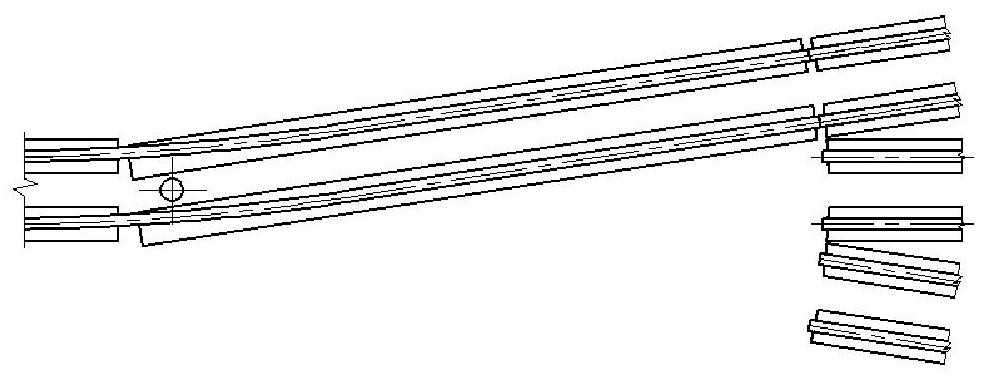

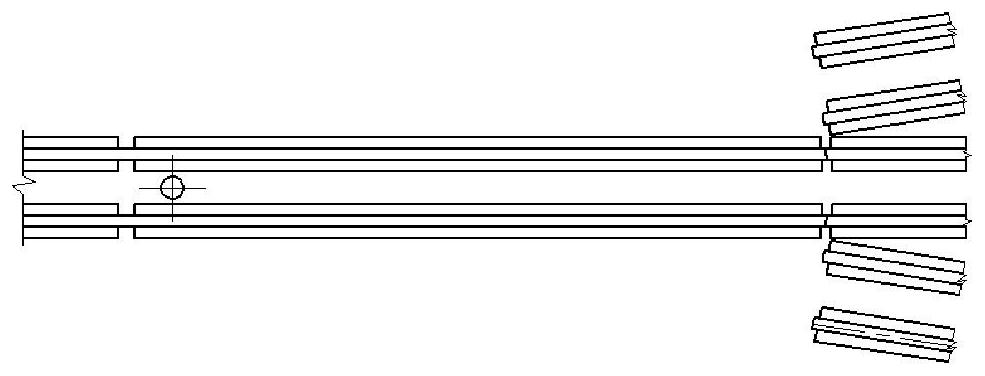

[0067] Such as Figure 1-4 As shown, the suspended freight monorail three-opening turnout includes fixed monorail open box-type track beam 1, monorail fixed gantry girder 2, rotary hinge 3, change-line rail A4, change-line monorail open box-type track beam A5, three-rail open box-type Fixed rail B6 of track beam, fixed beam A7 of three-rail open box-shaped track beam, fixed rail A8 of three-rail open box-shaped track beam, fixed beam B9 of three-rail open box-shaped track beam, three-rail open box-shaped track beam The fixed beam C10 of the three-rail open box track beam C11, the fixed rail D12 of the three-track open box track beam, the fixed beam D13 of the three-rail open box track beam, the fixing of the three-rail open box track beam Beam E14, fixed rail F15 of three-track open box-shaped track beam, fixed beam F16 of three-track open box-shaped track beam, fixed rail E17 of three-track open box-shaped track beam, change-line rail B18, change-line drive system 19, The th...

Embodiment 2

[0075] On the basis of Embodiment 1, the present invention also provides an installation process for the length-changing track length compensator, which is used for the installation of the compensator A100 and the compensator B200 respectively.

[0076] 1. The installation process of compensator A100 includes the following steps:

[0077] 1) Pass the fixed rail B6 of the three-rail open box-shaped track beam through several equidistantly arranged three-rail open box-shaped track beam fixed rail B adjustment pad iron A121 and the fixed rail B adjustment pad of the three-rail open box-shaped track beam The iron B122 is placed at the installation position of the fixed beam B9 of the three-rail open box-shaped track beam; the change-line rail B18 is placed through several equidistantly arranged change-line rail B adjustment shims A123, and the change-line rail B adjustment shim B124 is placed The installation position of the single-track open box track beam A21; adjust the relativ...

Embodiment 3

[0090] On the basis of Embodiment 1 and Embodiment 2, the present invention also provides a working process of a line-changing track length compensator, through the compensator A100 or compensator B200, the three-opening switch is changed from the middle position to the left position, Or the three-way switch changes from the middle to the right, or the three-way switch changes from the left to the middle, or the three-way switch changes from the left to the right, or the three-way switch changes from the right to the left track, or the three-way turnout changes from the right position to the middle position.

[0091] 1. The working process when the three-way turnout changes from the middle position to the left position includes the following steps:

[0092] (1) When the three-way turnout changes from the middle position to the left position, first start the servo motor A102 in the reverse direction, and drive the lifting slide A108 and the compensation rail A112 to move upward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com