Steel damping support with space universality

A universal steel damping technology, applied in the field of damping structures, can solve problems such as outstanding space occupation, difficult anchoring of damping units, and large vertical space, achieving high reliability, saving vertical space and horizontal space, and effective Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

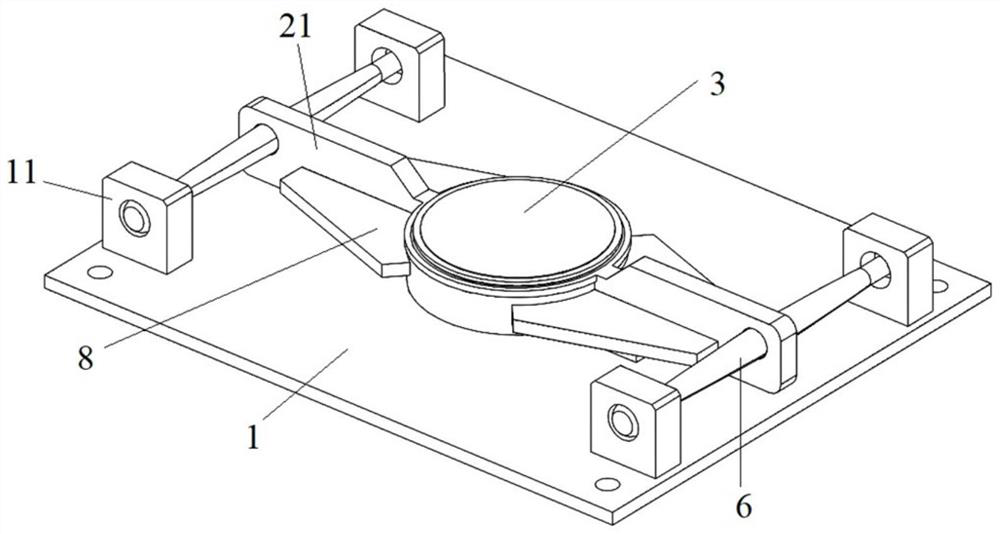

[0068] In order to adapt to various installation space scenarios in the bridge engineering support system, this embodiment provides a steel damping support with space universality. For its structure, see Figure 1 to Figure 6 etc., including:

[0069] Supporting module: it includes a bottom plate 1, a top plate 5, and a spherical cap assembly 3, the bottom plate 1 and the spherical cap assembly 3 are in movable contact and have a degree of freedom in the longitudinal direction, and the spherical cap assembly 3 and the top plate 5 are movable contact and have degrees of freedom along the transverse direction;

[0070] Seismic time limit module: including the first transmission rib 21, the second transmission rib 41, the first rod-shaped damping unit 6 and the second rod-shaped damping unit 7, the first transmission rib 21, the second transmission rib The plates 41 are respectively arranged longitudinally and transversely, the two ends of the first transmission rib 21 are respe...

Embodiment 2

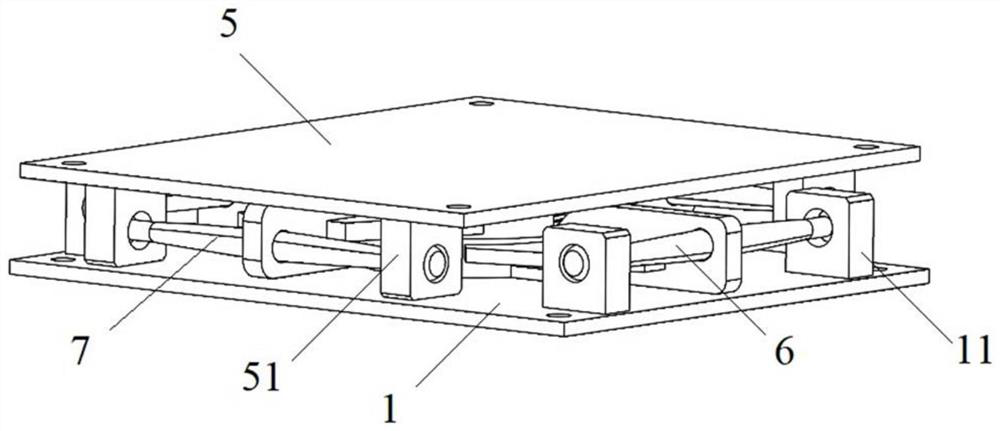

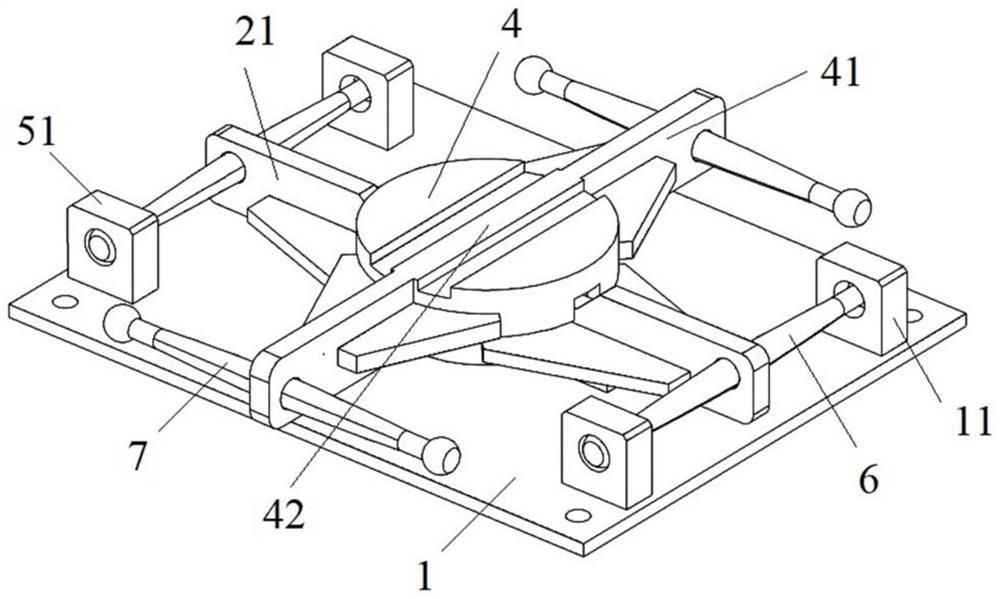

[0081] refer to Figure 8-Figure 9 , this embodiment provides a steel damping support with universal space, which is a vertical space-saving two-way movable support that provides higher tonnage damping force.

[0082] Different from Embodiment 1, the first rod-shaped damping unit 6 is arranged side by side in two along the direction of the first slideway, and is symmetrically arranged on both sides of the spherical cap assembly 3, and the second rod-shaped damping unit 7 is arranged along the second slideway. The road direction is arranged side by side as two, symmetrically arranged on both sides of the spherical cap assembly 3 . The first rod-shaped damping unit 6 and the second rod-shaped damping unit 7 are extended and arranged in an orthogonal manner along the horizontal direction.

Embodiment 3

[0084] refer to Figure 10-Figure 11 , this embodiment provides a steel damping support with universal space, which is a horizontal space-saving bidirectional movable support that provides higher tonnage damping force.

[0085] Different from Embodiment 2, in this embodiment, the first rod-shaped damping unit 6 and the second rod-shaped damping unit 7 are vertically stacked in an orthogonal manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com