Efficient denitration ammonia spraying mixer

A mixing device and denitrification technology, applied in mixers, fluid mixers, dispersed particle separation, etc., can solve problems such as flue gas uniformity distribution deviation, reduce mixing distance, improve flue gas distribution uniformity, and avoid death Effects of Zones and Dead Zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following non-limiting examples illustrate the invention.

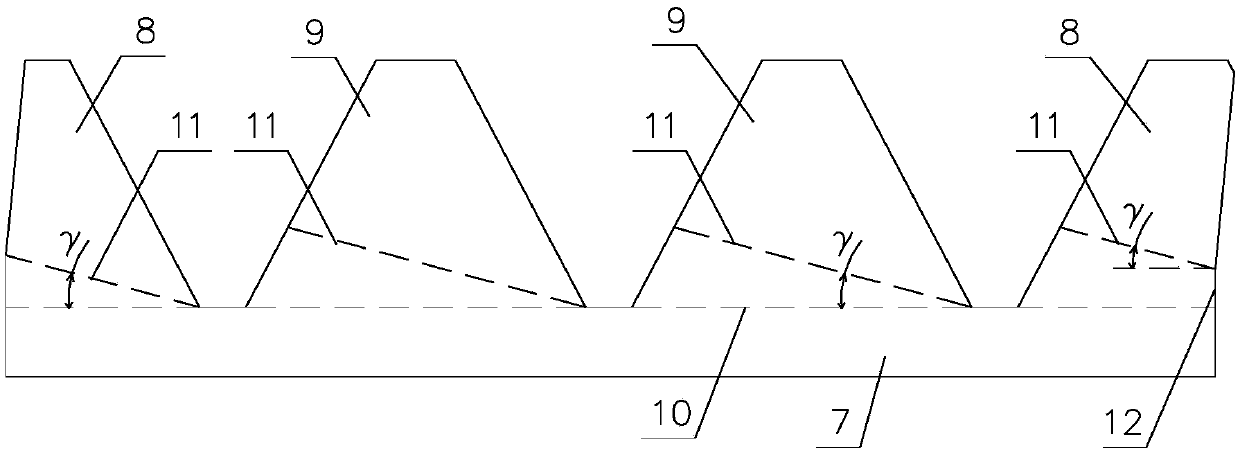

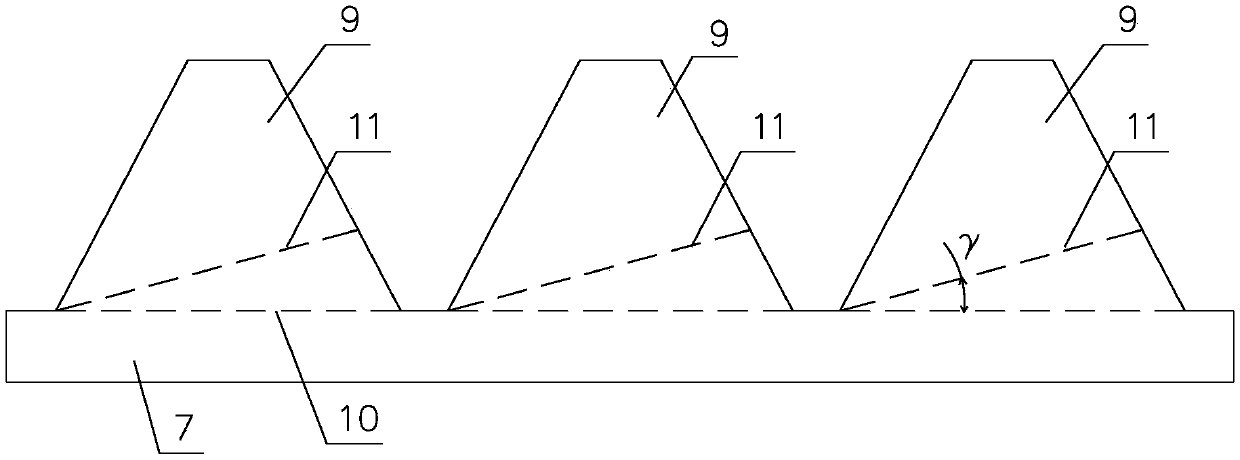

[0040] refer to Figures 1 to 11 shown, where Figure 9The left and right direction in the paper is the flue width direction, the up and down direction is the flue depth direction, and the vertical direction is the flue length direction; similarly, Figure 10 The left and right direction in the paper surface is the flue width direction, the up and down direction is the flue length direction, and the vertical paper direction is the flue depth direction.

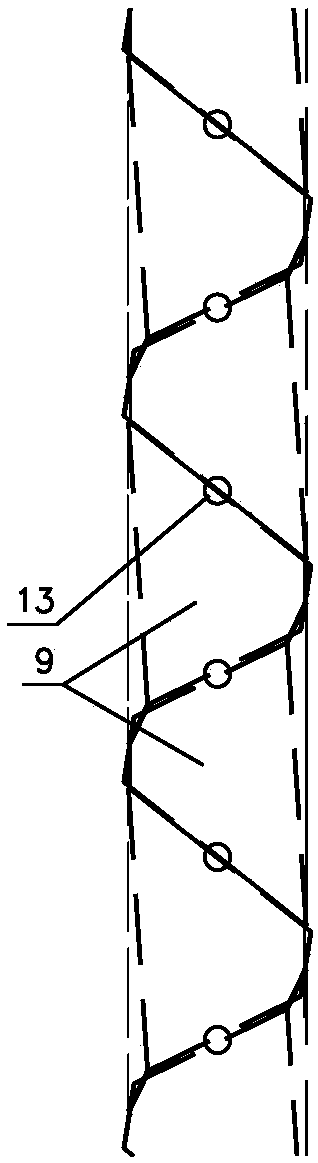

[0041] refer to Figures 9 to 11 As shown, a high-efficiency denitrification ammonia injection mixing device includes ammonia injection nozzle 13, and mixing unit A1 and mixing unit B2 in a long row structure. The lengths of mixing unit A1 and mixing unit B2 all extend along the flue depth direction, and mixing The unit A1 and the mixing unit B2 are installed in rows at intervals along the width direction of the flue and cover the entire flue section uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com