Inlaid type laminate side-spraying nose cone

A mosaic-type, plate-side technology, which is applied in the direction of aerospace vehicle guides, can solve the problems of low precision of the vehicle and lack of lateral jet function, and achieve the effect of light weight, simple structure and strong space adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

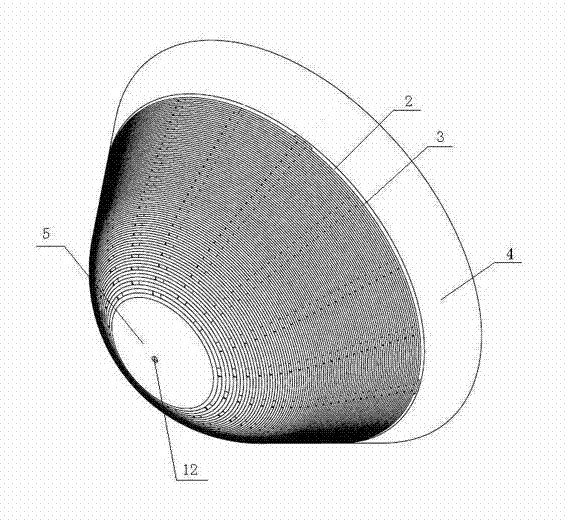

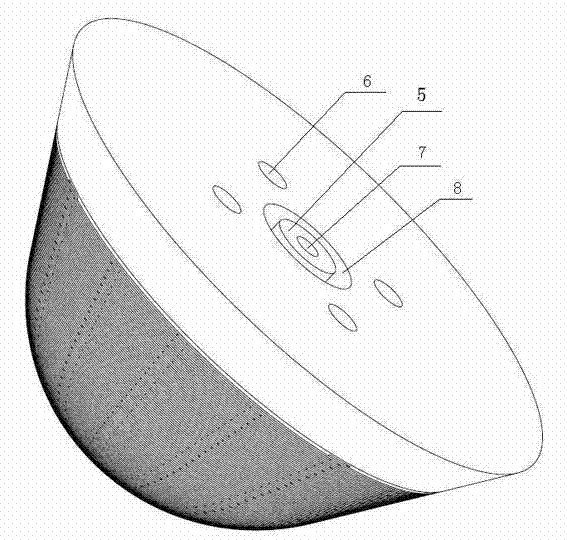

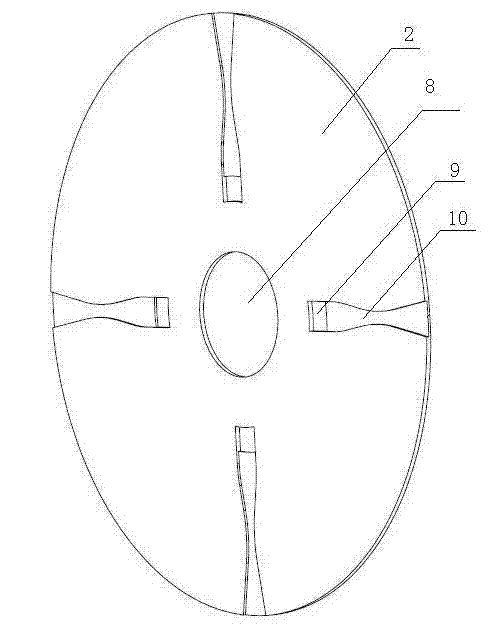

[0029] Such as figure 1 , figure 2 As shown, a mosaic-type laminate side spray nose cone includes a circular base 4, and the top surface of the circular base 4 is provided with a spherical cone-shaped sweating laminate stack. The sweating laminate stack is composed of multiple The circular sweating laminates 15 and 16 with increasing heights and decreasing radii are coaxially stacked; the center of the circular base 4 is provided with a base sweating main channel 8 that leads to the stacked body of spherical conical laminates for cooling. , and is provided with a fixed rod 5 passing through the main sweating channel 8 of the bottom platform and a stacked body of sweating laminates, such as Figure 9 As shown, the top of the fixed rod 5 is arc-shaped and the top of the fixed rod 5 is covered on the top of the laminated body of sweating; the fixed rod 5 is provided with a nozzle 12 leading to the cooling medium and a cooling medium inflow inlet 7 ; A side spray mechanism is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com