Charging power supply test load and system

A charging power supply and load testing technology, which is applied in power supply testing, improvement of basic electrical components, etc., can solve problems such as inability to realize fine adjustment of back pressure and residual voltage on energy storage capacitors, achieve precise residual voltage control, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

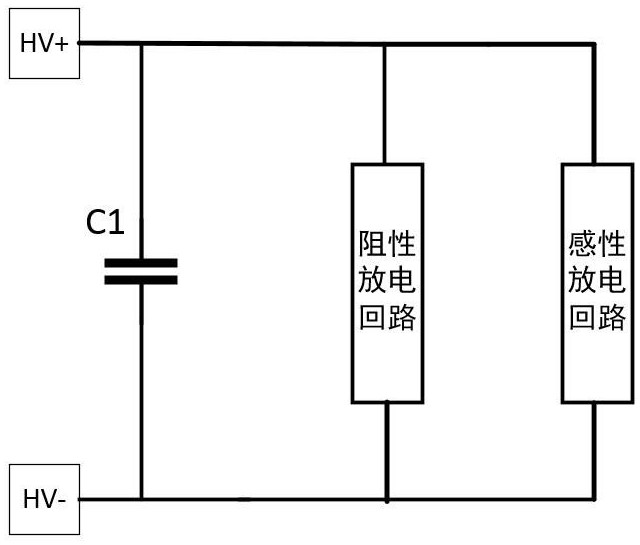

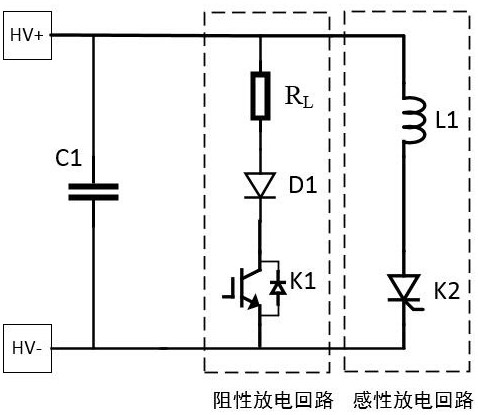

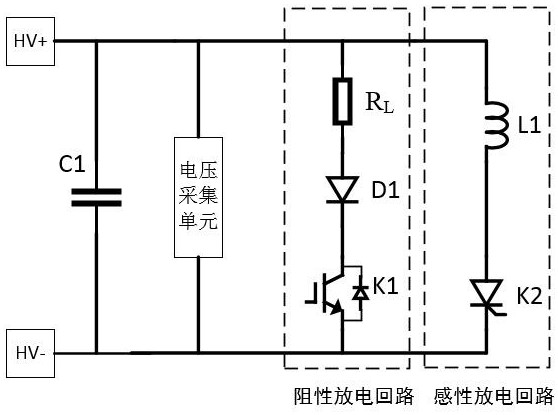

[0039] Such as figure 1As shown, in Embodiment 1, a charging power supply test load specifically includes an energy storage capacitor connected in parallel with the output terminal of the charging power supply, a resistive discharge circuit connected in parallel with the energy storage capacitor, and a Inductive discharge circuit. Specifically, the resistive discharge circuit is to discharge the charging power source to be tested through the resistive load, and the inductive discharge circuit is to discharge the charging power source to be tested through the inductive load; the present invention can be applied to load characteristic test scenarios of various charging power sources, including The load test scene of the charging power supply with energy recovery circuit and the load test scene of the charging power supply with energy recovery circuit. When the test load of the present invention is applied to a load test of a charging power source without an energy recovery circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com