An automatic increasing and decreasing yarn carrier for three-dimensional weaving with large yarn storage and its use method

A technology of three-dimensional weaving and yarn carrier, which is applied in the field of three-dimensional weaving, can solve problems such as low efficiency, unsatisfactory comprehensive forming performance, and complicated weaving process, and achieve the goal of improving stability, meeting structural strength requirements, and increasing yarn storage capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

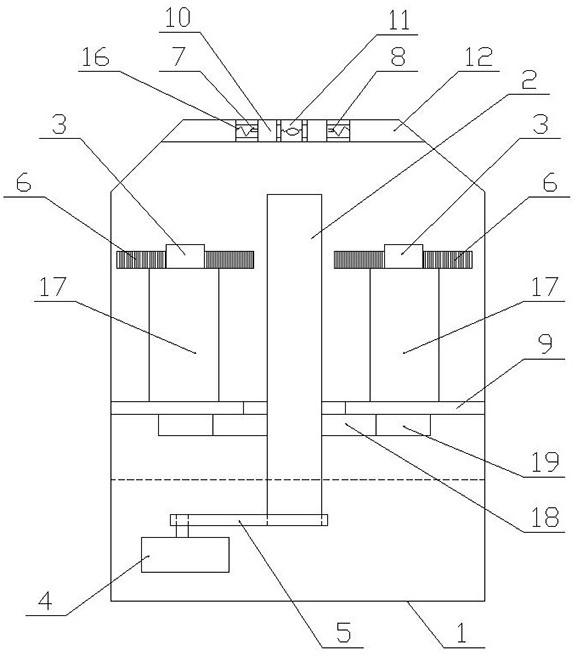

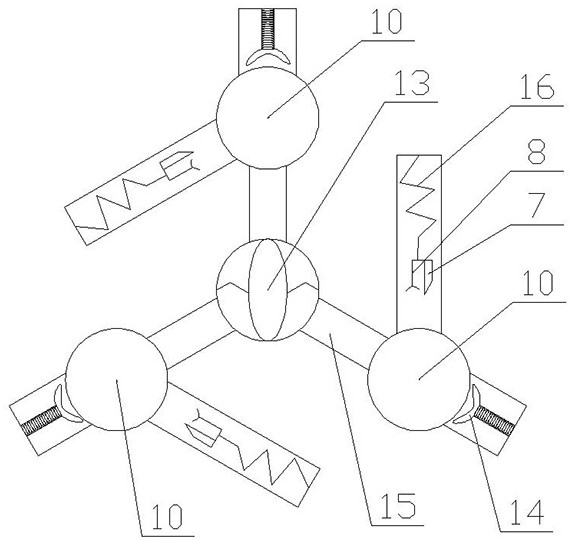

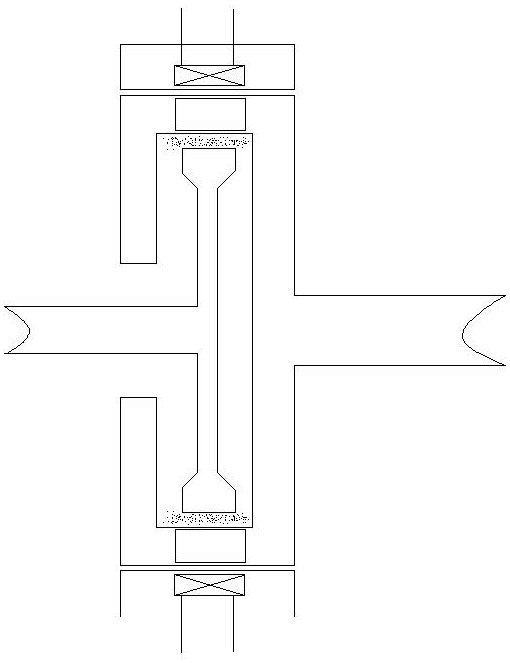

[0034] An automatic increase and decrease yarn carrier for large yarn storage in three-dimensional weaving according to the present invention, comprising a housing 1, a top plate 12, a motor drive device, a support plate 9, a yarn storage device, a yarn increase and decrease device, and a knotting ring 13; The specific structure is as Figure 1~5As shown, the top plate 12 is fitted up and down with the shell, and is screwed to form a vertically arranged hollow cuboid structure; a support plate 9 is horizontally provided at the lower middle position inside the shell 1, and the support plate 9 is surrounded by The end faces are respectively fixedly connected to the inner side walls of the housing 1, and the upper surface of the support plate 9 is in the form of an equilateral triangle and three yarn storage devices are vertically provided; figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com