A large-capacity yarn storage device for three-dimensional automatic knitting equipment

A yarn storage, large-capacity technology, used in looms, textiles, textiles and papermaking, etc., can solve the problems of high three-dimensional weaving cost, difficult transmission, slow speed, etc. Even tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

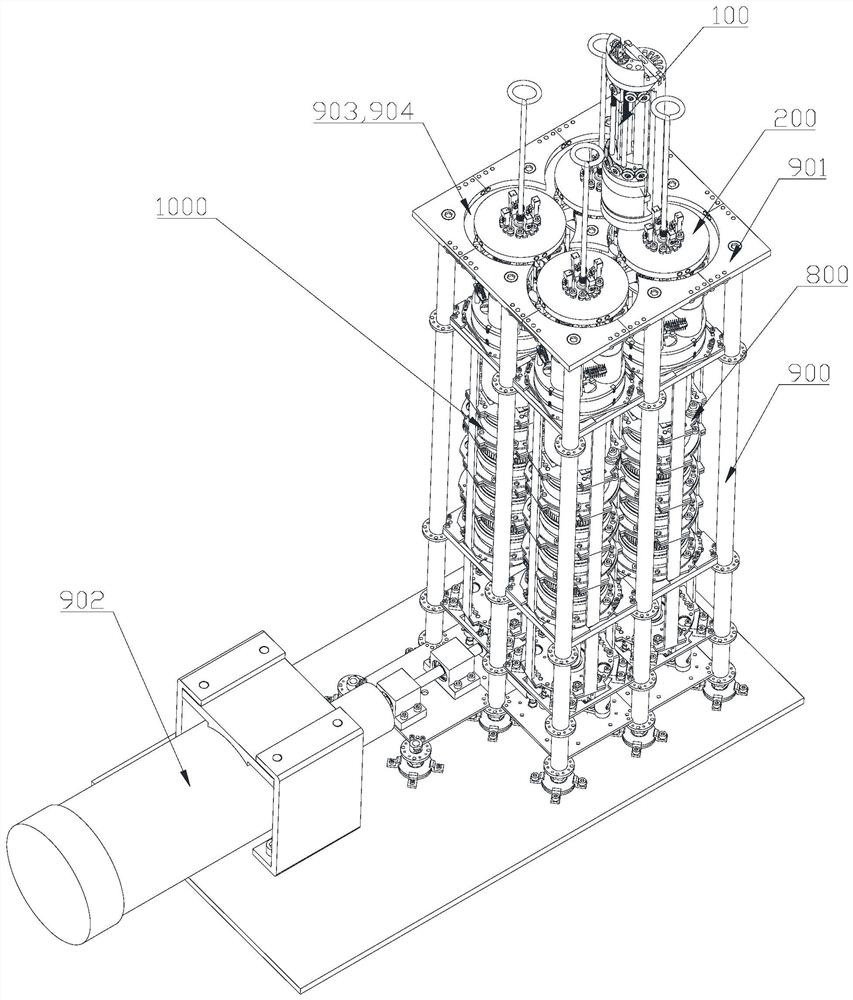

[0052] Such as figure 1 As shown, a three-dimensional automatic weaving device 1000 is introduced in this embodiment, and the three-dimensional automatic weaving device 1000 includes a frame 900, a plurality of yarn storage devices 100 and a plurality of weaving stations 800, and the weaving stations 800 are arranged in the hollow inside of the frame 900 , and form an array within the frame 900. During the knitting process, the knitting station 800 rotates circumferentially around the axis of the knitting station 800, and under the clamping action of the knitting station 800, each yarn storage device 100 wraps around the outer circumference of the knitting station 800 and on the end face of the frame 900 close to the knitting surface move so that the yarns carried by each yarn storage device 100 knit each other to form a three-dimensional knitting fabric at the knitting surface.

[0053] In this embodiment, the frame 900 is located at one end close to the knitting surface and...

Embodiment 2

[0058] Such as figure 1 As shown, in this embodiment, the yarn storage device 100 includes a base disc column 107 and a base 101, the base 101 and the base disc column 107 both extend along the axial direction of the knitting station 800, and the base disc column 107 is arranged on the side of the yarn storage device 100 One end away from the weaving surface, the base 101 is arranged on the end of the yarn storage device 100 away from the weaving surface, the base disc column 107 is fixedly arranged with the base 101, the diameter of the base 101 is much larger than the diameter of the base disc column 107, the base disc column 107 and the base 101 coaxial setting.

[0059] In this embodiment, the base 101 rests on the support plate 901, the base disc column 107 extends into the frame 900 through the circular track 904, and the knitting station 800 clamps the base disc column 107 and rotates circumferentially to drive the yarn storage device 100 It moves around the outer circ...

Embodiment 3

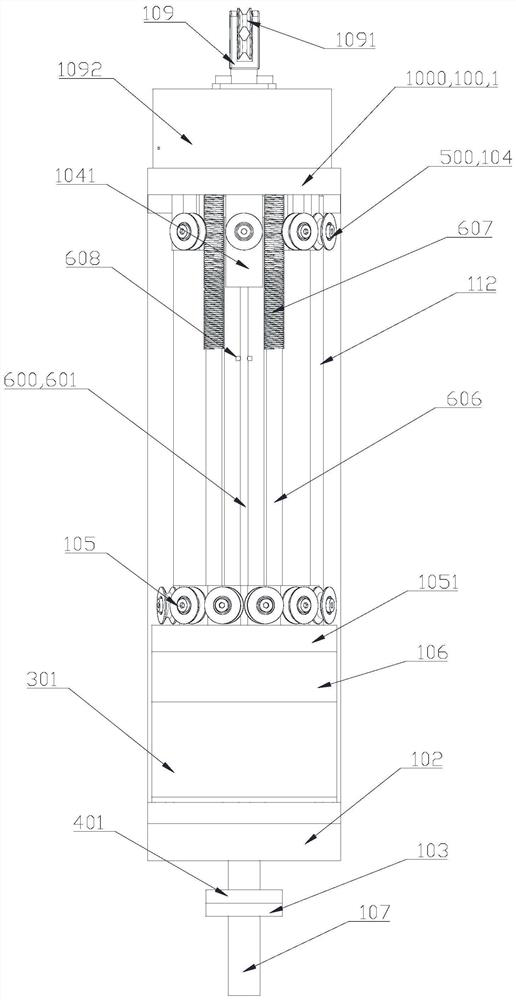

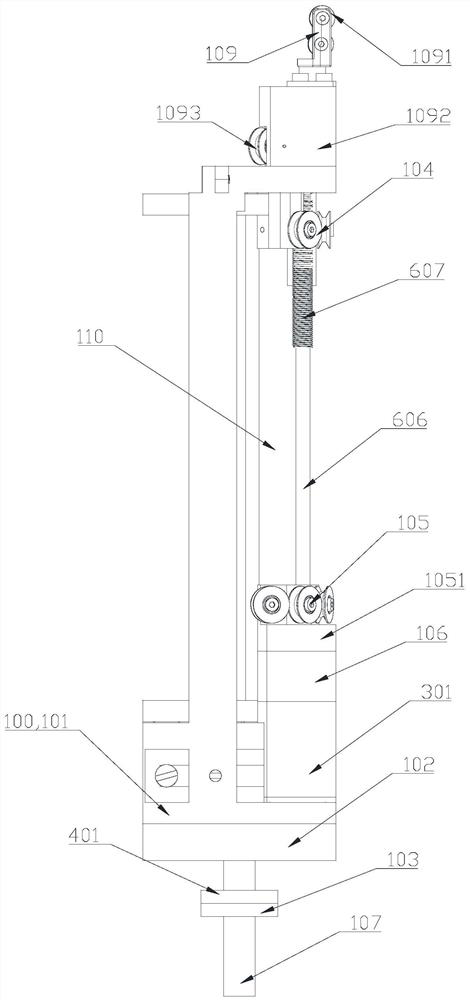

[0068] Such as Figure 2 to Figure 8 As shown, a large-capacity yarn storage device 100 for a three-dimensional knitting device 1000 is introduced in this embodiment. The thread transfer unit 500 is used to transfer the yarn on the yarn storage tube 100 from the yarn storage tube 100 to the knitting surface, and the tension adjustment unit 600 is used to adjust the yarn tension during the yarn transfer process, so that the yarn is Unwind under tension. By setting the yarn transfer unit and the tension adjustment unit,

[0069] In this embodiment, the yarn transfer unit 500 includes an upper wire passing wheel 104 and a lower wire passing wheel 105, the upper wire passing wheel 104 is arranged at one end of the yarn storage device 100 close to the knitting surface, and the lower wire passing wheel 105 is arranged at the yarn storage device At the end of 100 away from the weaving surface, the yarn is delivered to the weaving surface from the yarn storage tube 108 through the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com