Road and bridge steel mould structure with high supporting performance

A technology of road and bridge and steel formwork, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of lack of auxiliary fixing mechanism, fixed installation, inconvenient T-shaped struts, etc., and achieve the effect of disassembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

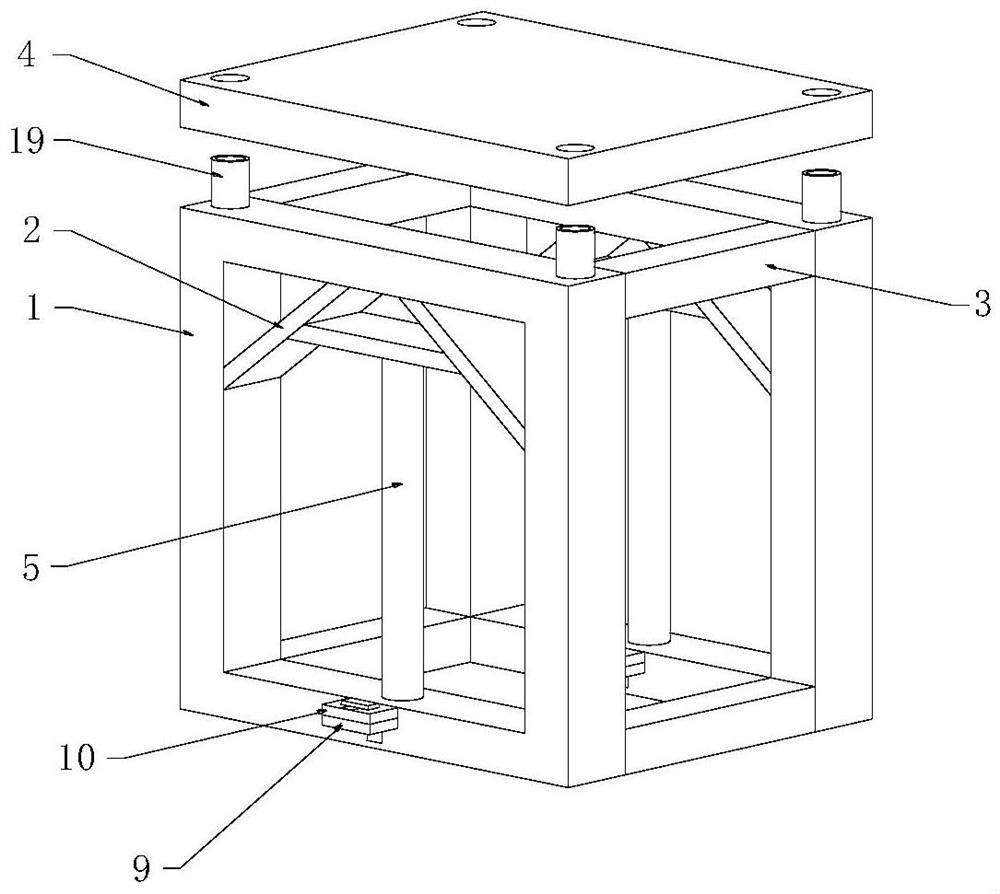

[0027] see Figure 1-4 As shown, a road and bridge steel mold structure with good support includes a square frame 1, a support block 2, a connecting rod 3, a top plate 4, a T-shaped strut 5 and a clamping mechanism; the square frame 1 is internally fixed symmetrically Install two support blocks 2, the square frame 1 is provided with two groups, the two groups of square frames 1 are fixedly connected by connecting rods 3, and the inner bottom of the square frame 1 is equipped with T-shaped struts 5. The left and right ends of the T-shaped strut 5 are attached to the two support blocks 2 respectively, the top plate 4 is installed on the top of the square frame 1, and the bottom end of the top plate 4 is attached to the top end of the connecting rod 3;

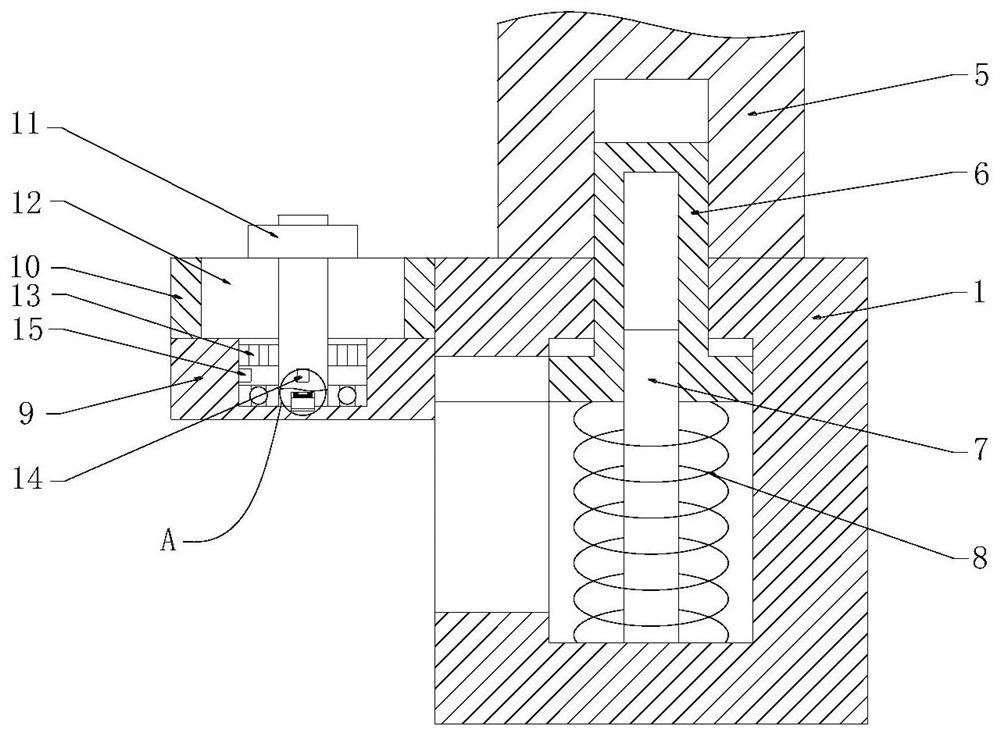

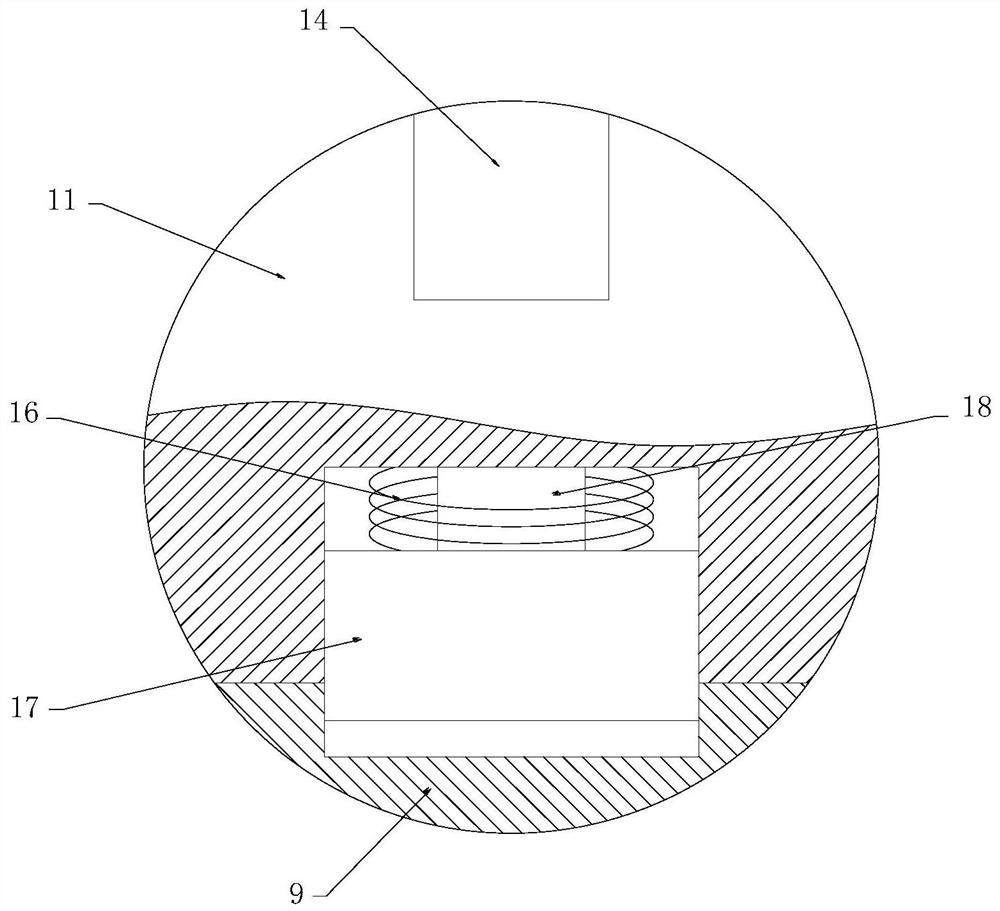

[0028]The clamping mechanism includes a T-shaped round bar 6, a guide rod 7, a spring 8, a fixed block 9, a fixed block 2 10, a T-shaped round block 11 and a square through groove 12, and the inner bottom of the square frame 1 A...

Embodiment 2

[0037] see Figure 5 As shown in Comparative Example 1, as another embodiment of the present invention, a support rod 26 is fixedly installed on the lower side of the rear end of the square frame 1, and an arc-shaped limit block 25 is installed on the top of the support rod 26, The annular side of the T-shaped strut 5 fits with the arc-shaped limit block 25, and the rear end of the support rod 26 is rotated with a rotating rod 27, and the upper side of the front end of the rotate rod 27 is in contact with the arc-shaped limit block 25. Fitting, the lower side of the front end of the rotating rod 27 is fixedly equipped with a fixed pin, the ring side of the fixed pin is equipped with a torsion spring two and a bearing, and the outer side of the torsion spring two and the outer side of the bearing are all fixedly installed inside the support rod 26, so A T-shaped block 29 is installed on the upper side of the rear end of the rotating rod 27, and the front end of the T-shaped blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com