Acid-resistant and oil-resistant oil cylinder rack

A rack and oil technology, applied in the direction of fluid pressure actuation devices, can solve the problems of high efficiency, inconvenient installation, disassembly and maintenance, etc., and achieve the effects of high efficiency, long service life and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

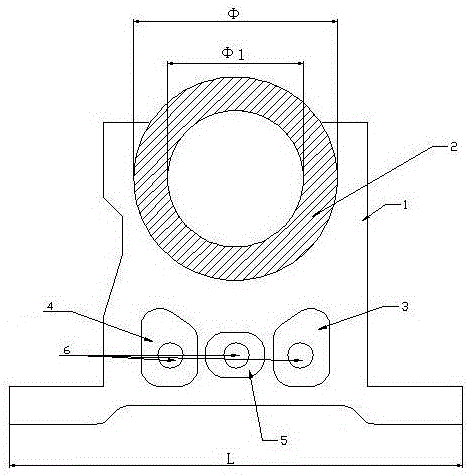

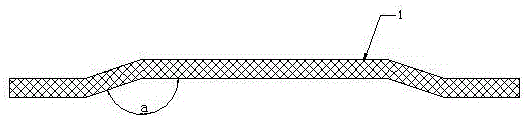

[0018] Such as figure 1 , figure 2 with image 3 The shown acid-resistant and oil-resistant oil cylinder frame includes a support plate 1, a limit ring 2 arranged on the support plate 1, and a first groove 3 arranged on the support plate 1 and below the limit ring 2, The second groove 4, the third groove 5, and the positioning holes 6 respectively arranged in the first groove 3, the second groove 4, and the third groove 5, wherein, one end of the support plate 1 is set as a plate-type concave Structure; the support plate 1, the first groove 3, the second groove 4 and the third groove 5 are integrally formed by alloy stainless steel; the length L of the plate concave structure at one end of the support plate 1 is 235mm-245mm, and the limit ring The outer diameter Φ of 2 is 70mm-80mm, and the inner diameter Φ1 is 105mm-115mm.

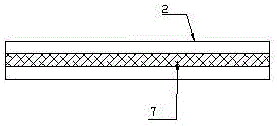

[0019] Further preferably, the acid-resistant and oil-resistant oil cylinder frame also includes a limit groove 7 arranged in the limit ring 2, which...

Embodiment 2

[0021] Such as figure 1 , figure 2 with image 3 The shown acid-resistant and oil-resistant oil cylinder frame includes a support plate 1, a limit ring 2 arranged on the support plate 1, and a first groove 3 arranged on the support plate 1 and below the limit ring 2, The second groove 4, the third groove 5, and the positioning holes 6 respectively arranged in the first groove 3, the second groove 4, and the third groove 5, wherein, one end of the support plate 1 is set as a plate-type concave Structure; the support plate 1, the first groove 3, the second groove 4 and the third groove 5 are integrally formed by alloy stainless steel; The outer diameter Φ is 75mm, and the inner diameter Φ1 is 110mm.

[0022] Further preferably, the acid-resistant and oil-resistant oil cylinder frame also includes a limit groove 7 arranged in the limit ring 2, which is connected with the limit protrusion of the oil cylinder during assembly to increase the connection stability; the support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com