Connected type pressure-resistant flange plate

A one-piece, pressure-resistant technology, applied in flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of inconvenient installation, disassembly and maintenance, high use efficiency, long service life and reasonable design structure , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

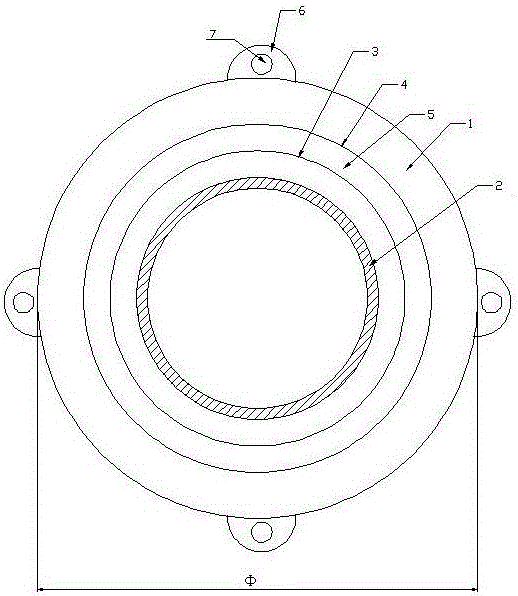

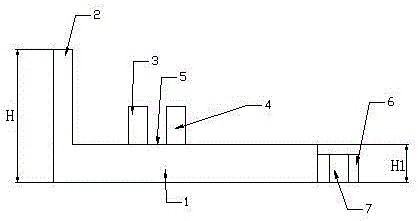

[0017] Such as figure 1 and figure 2 The shown one-piece pressure-resistant flange includes a flange body 1, a circular slot 2 arranged on the flange body 1, and a circular slot arranged on the flange body 1. 2 between the first limit ring 3, the second limit ring 4, wherein the diameter of the first limit ring 3 is smaller than the second limit ring 4, and is arranged on the first limit ring 3, the second limit ring The card groove 5 between the rings 4, and several positioning lugs 6 arranged on the outer surface of the flange body 1, and the positioning holes 7 respectively arranged in the positioning lugs 6; the flange body 1, the circular The card slot 2, the first limit ring 3, the second limit ring 4, the card slot 5 and the positioning ear plate 6 are integrally formed of carbon steel; the diameter of the flange body 1 is 230mm-240mm, and the flange The height H of the body 1 and the circular slot 2 is 70mm-80mm, and the height H1 of the positioning lug 6 is 20mm-30...

Embodiment 2

[0021] Such as figure 1 and figure 2 The shown one-piece pressure-resistant flange includes a flange body 1, a circular slot 2 arranged on the flange body 1, and a circular slot arranged on the flange body 1. 2 between the first limit ring 3, the second limit ring 4, wherein the diameter of the first limit ring 3 is smaller than the second limit ring 4, and is arranged on the first limit ring 3, the second limit ring The card groove 5 between the rings 4, and several positioning lugs 6 arranged on the outer surface of the flange body 1, and the positioning holes 7 respectively arranged in the positioning lugs 6; the flange body 1, the circular The card slot 2, the first limit ring 3, the second limit ring 4, the card slot 5 and the positioning ear plate 6 are integrally formed of carbon steel; the diameter of the flange body 1 is 235mm, and the flange body 1 The height H of the circular draw-in slot 2 is 75mm, and the height H1 of the positioning ear plate 6 is 25mm.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com