Anti-backflow method and device applied to heat dissipation equipment and heat dissipation system

A technology of backflow prevention device and heat dissipation device, which is applied to structural parts of electrical equipment, cooling/ventilation/heating modification, modification using gaseous coolant, etc. Guaranteed cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

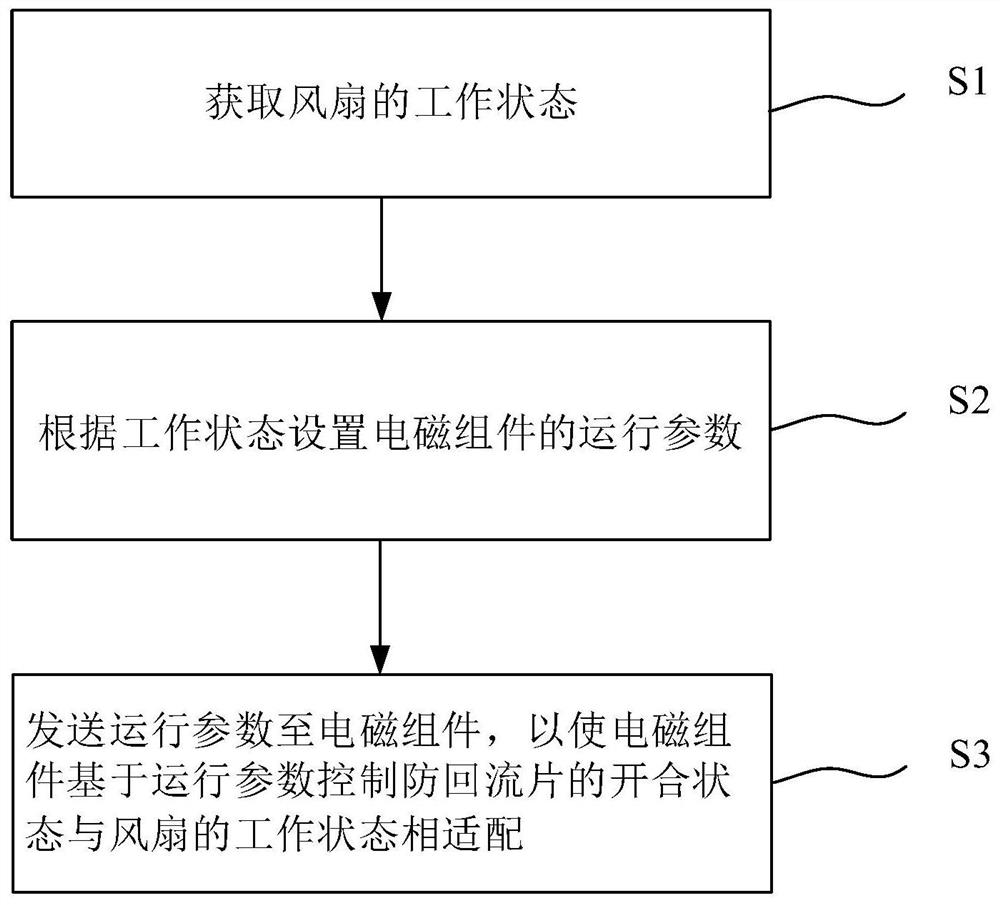

[0061] This embodiment provides a backflow prevention method applied to a heat dissipation device. The heat dissipation device includes at least two fans arranged side by side and anti-backflow sheets of magnetic materials arranged corresponding to the fans. seefigure 1 , the backflow prevention method includes the following steps:

[0062] S1. Obtain the working status of the fan;

[0063] S2. Set the operating parameters of the electromagnetic components according to the working state;

[0064] S3. Sending the operating parameters to the electromagnetic assembly, so that the electromagnetic assembly controls the opening and closing state of the anti-backflow sheet to match the working state of the fan based on the operating parameters.

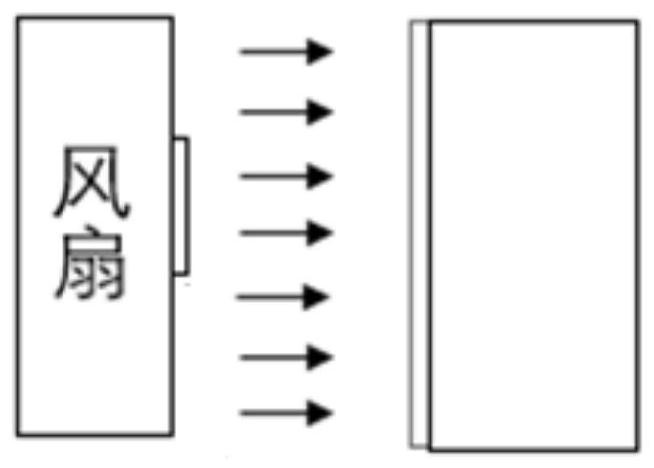

[0065] In this embodiment, the heat dissipation device is specially set up for the heat dissipation of other main equipment with relatively large power and high calorific value, usually it may be a fan unit. The heat dissipation device may...

Embodiment 2

[0108] see Figure 4-6 , this embodiment also provides an anti-backflow device applied to heat dissipation equipment. The heat dissipation equipment includes at least two fans 1 arranged side by side and an anti-backflow sheet 2 of magnetic material corresponding to the fans 1. The anti-backflow device includes a controller and the electromagnetic assembly 3;

[0109] The electromagnetic assembly 3 is arranged on both sides of the air outlet of the fan; the controller is electrically connected to the electromagnetic assembly 3; the controller is used to implement the anti-backflow method in Embodiment 1, so as to control the electromagnetic assembly 3 to match the working state of the fan 1 .

[0110] in, Figure 4 is an overall side view of the heat sink and backflow preventer, Figure 5 for its front view, Figure 6 for its top view.

[0111] As a preferred embodiment, the fan 1 includes a PIN pin interface, and the controller is used to read the PIN pin interface to ob...

Embodiment 3

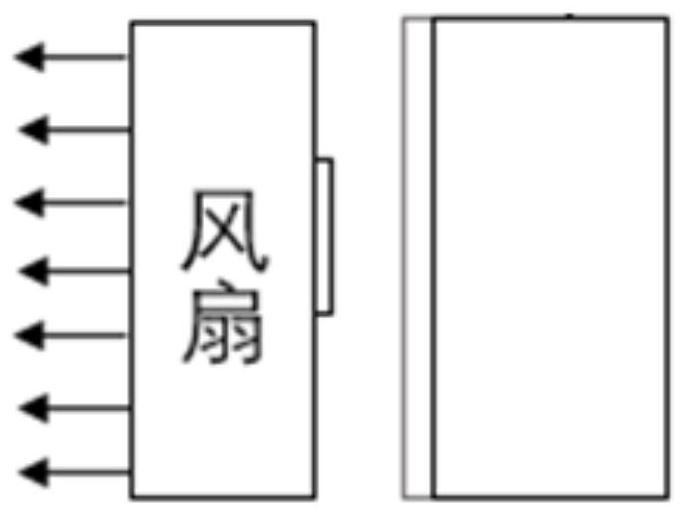

[0122] see Figure 7 , this embodiment also provides a heat dissipation system, including a heat dissipation device 4 and an anti-backflow device; the anti-backflow device also includes a connecting part 5 . A connection part 5 is provided at the central axis of the air supply port of each fan 1; electromagnetic assemblies 3 are respectively provided on both sides of the air supply port of each fan 1; When the return piece 2 is rotated by the connecting part 5 and rotated axially to the position parallel to the air outlet, it will be attached to the electromagnetic components 3 arranged on both sides of the fan 1 to close the air outlet. Please refer to Figure 8 . Of course, according to the installation position of the electromagnetic assembly 3, the anti-backflow sheet 2 can also be flipped in other ways or postures, as long as the air outlet of the fan 1 is closed to block the backflow gas.

[0123] The arrangement in this embodiment can better control the anti-backflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com