Horizontal coiled steaming device special for spandex

A horizontal, spandex technology, applied in the field of pan steaming devices, can solve the problems of inability to vaporize spandex, waste of materials, low heat efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

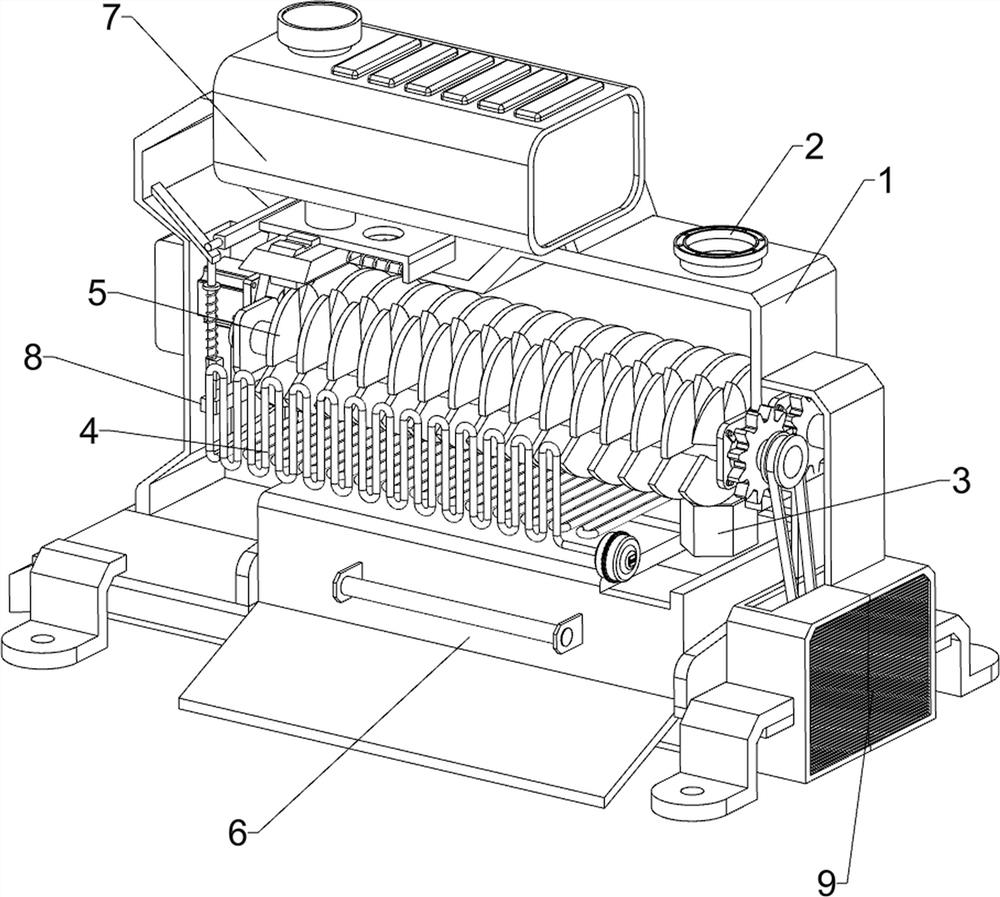

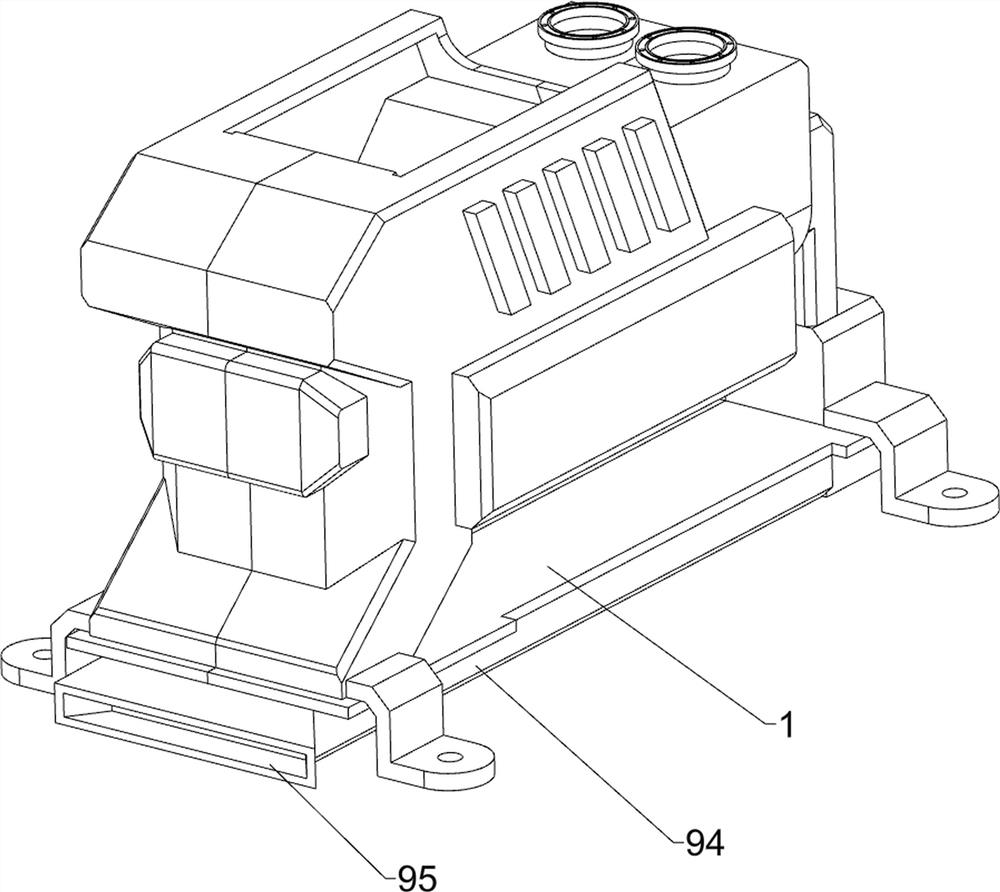

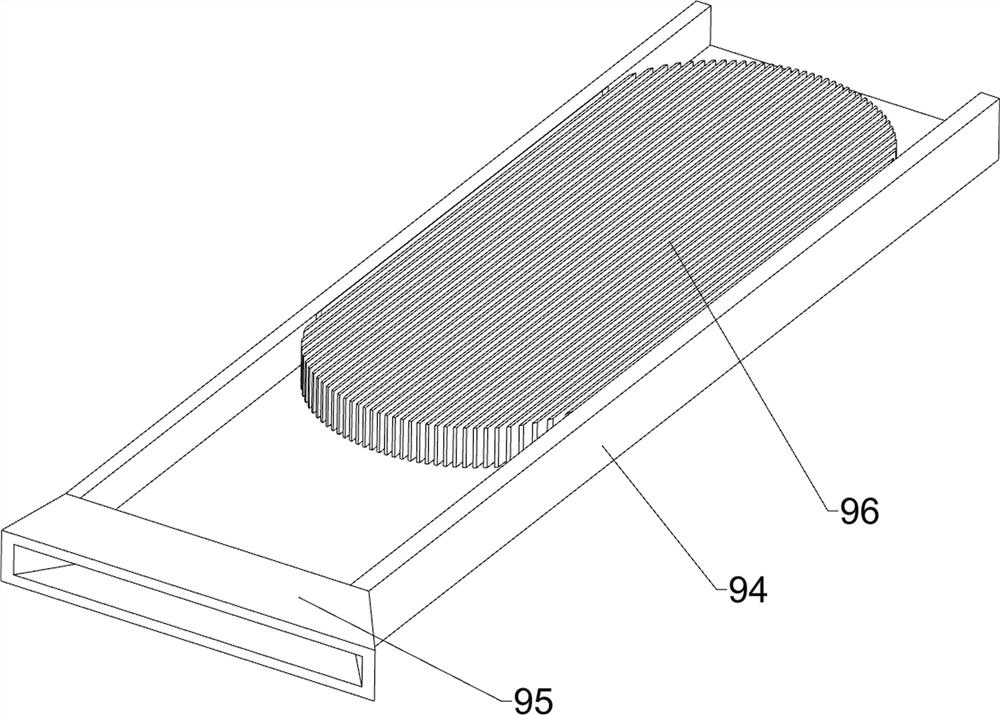

[0035] A special horizontal pan steaming device for spandex, such as Figure 1-Figure 8 As shown, it includes a casing 1, a discharge pipe 2, a discharge port 3, a heating mechanism 4, a rotating mechanism 5 and a collection mechanism 6. A discharge port 3 is provided inside the side, a heating mechanism 4 is provided inside the housing 1 , a rotating mechanism 5 is provided on the upper side inside the housing 1 , and a collecting mechanism 6 is provided on the lower side of the housing.

[0036] The heating mechanism 4 includes a rotating shaft 40, a helical blade 41, a heater 42 and a heating tube 43. The upper side of the housing 1 is rotatably provided with a rotating shaft 40, and the rotating shaft 40 is provided with a helical blade 41. The housing 1 A heater 42 is arranged symmetrically front and back in the middle of the right side, and a heating pipe 43 is arranged inside the casing 1 , and the heating pipe 43 is connected to the heater 42 .

[0037] The rotating m...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 9-Figure 15 As shown, it also includes a blanking assembly 7, and the blanking assembly 7 includes a material box 70, a feed pipe 71, a special-shaped plate 72, a limit block 73, a first spring 74, a wedge rod 75, a mounting block 76 and a second Spring 77, a material box 70 is provided on the upper left side of the housing 1, a feed pipe 71 is provided on the left side of the bottom of the material box 70, a limit block 73 is provided on the upper left side inside the housing 1, and a special-shaped plate is provided on the top of the limit block 73 for sliding 72. A through hole is opened on the special-shaped plate 72, and the through hole on the special-shaped plate 72 cooperates with the feed pipe 71. The center is provided with mounting block 76 symmetrically front and back, and the inside of mounting block 76 is provided with wedge-shaped rod 75 slidingly. Two springs 77 are all wound on the wedge bar 75 .

[0042] Als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com