Extensible anchor rod with shear resistance function for coal mine tunnel

A coal mine roadway and lengthening bolt technology, which is applied in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve problems such as failure of support, collapse of gangway, roof fall of roadway, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

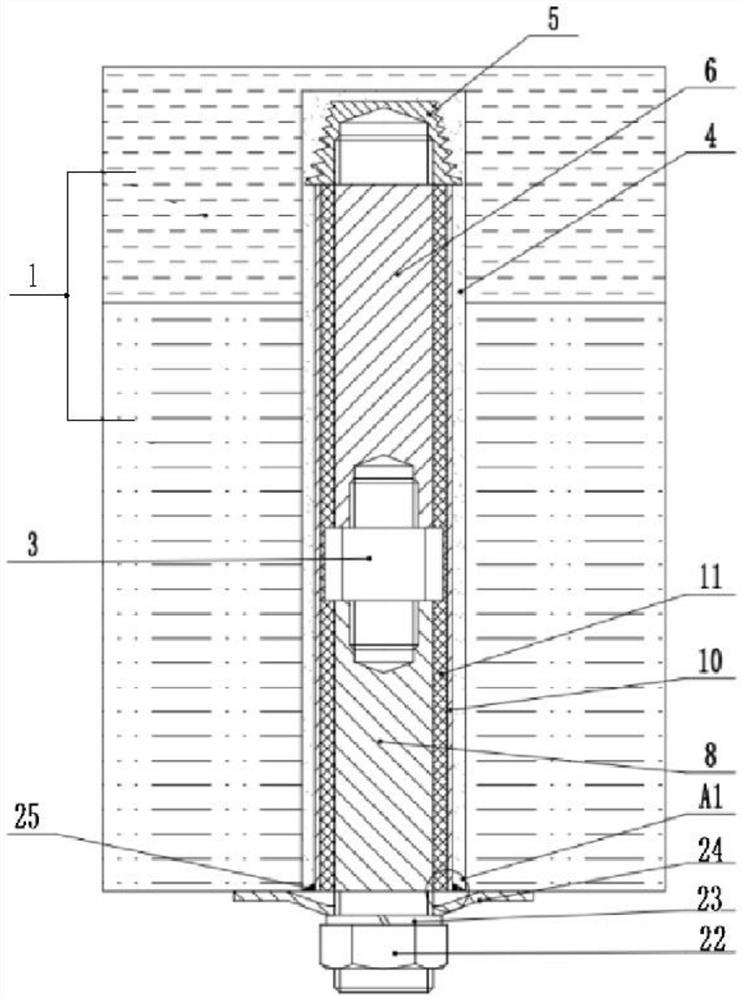

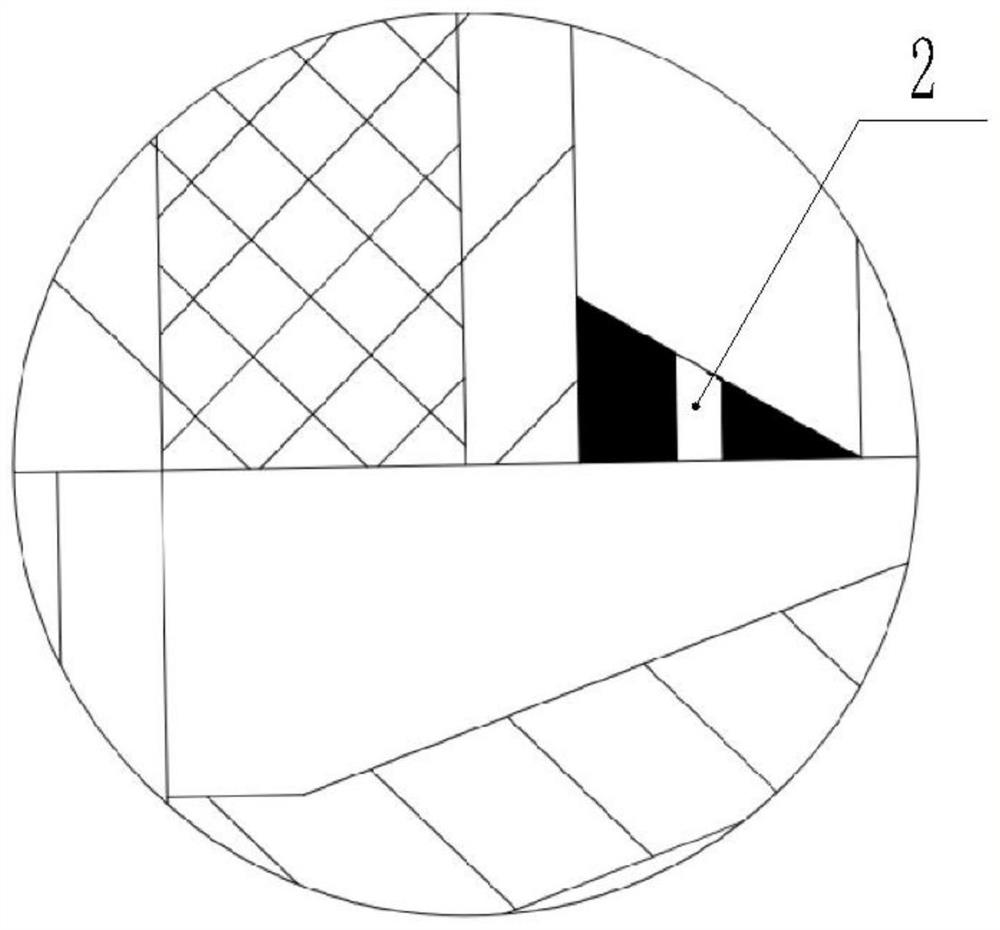

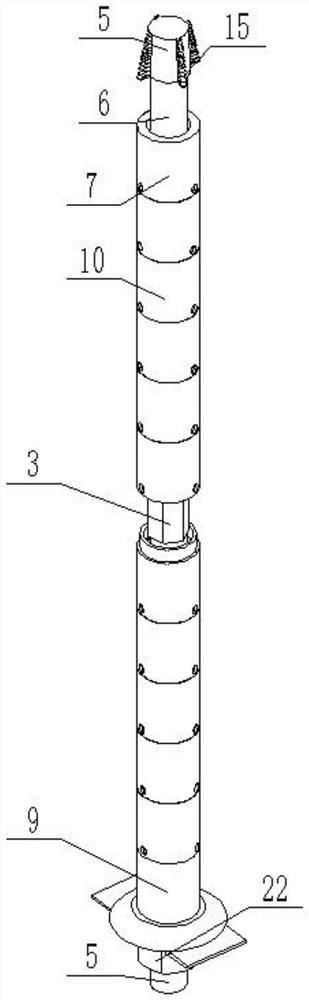

[0035] refer to Figure 1-7 , the present invention provides an extendable bolt with shear resistance function for coal mine roadway, which includes a fixed part and a connectable part arranged in the surrounding rock 1, the connectable part and the fixed part are threadedly connected by high-strength connecting bolts 3, The rock wall of the surrounding rock 1 is fixed with a top plate, and the bottom surface of the top plate is provided with an anchor hole, the top of the anchor hole extends upwards into the surrounding rock 2, and an anchor layer 4 is set between the outer wall of the connectable part and the fixed part and the anchor hole;

[0036] The connectable part includes an anchor head 5 and an extendable rod body 6; the anchor head 5 and the top of the extendable rod body 6 are threaded, and the top of the extendable rod body 6 is provided with a top sleeve 7 under the anchor head 5, The bottom surface of the connectable long rod body 6 is threadedly connected with ...

Embodiment 2

[0067] refer to Figure 8-9 , in order to promote the resin anchoring agent to break more thoroughly and enhance the cohesiveness, and at the same time improve the anchoring force, an auxiliary anchoring mechanism is set in the first butt joint thread cavity in this embodiment;

[0068] The auxiliary anchor mechanism includes an anchor assembly, an abutment plate 26, a return spring 27 and an abutment rod 28;

[0069] The top of the return spring 27 is affixed to the top surface of the first butt thread cavity, the bottom of the return spring 27 is affixed to the top surface of the abutment rod 28, the bottom surface of the abutment rod 28 is affixed to the top surface of the abutment plate 26, and the abutment rod 28 The outer wall is provided with a number of anchoring components; the outer wall of the extendable shear sleeve 10 is provided with a number of auxiliary holes 32 suitable for the anchoring components;

[0070] The anchor assembly includes a hinged seat 29, a hi...

Embodiment 3

[0075] refer to Figure 10 , in order to realize docking between the auxiliary rod 31 and the auxiliary hole 32 in Embodiment 2, a positioning mechanism is provided in this embodiment; the positioning mechanism includes a positioning ring plate 33, and the positioning ring plate 33 is sleeved on the long shear sleeve 10 The top of the positioning ring plate 33 is fixed to the outer wall of the long shear sleeve 10. The bottom surface of the positioning ring plate 33 is fixed with a number of positioning columns 34 at equal intervals in the circumferential direction. The top surface of the top sleeve 7 is provided with a number of The position of the positioning post 34 corresponds to the positioning groove, the positioning post 34 is plugged into the positioning slot, and the auxiliary hole 32 corresponds to the position of the auxiliary rod 31 .

[0076] After the top sleeve 7 is positioned, the remaining extendable shear sleeve 10 is connected to the bottom sleeve 9 by screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com