Scroll compressor

A technology of scroll compressors and scroll parts, which is applied in the field of scroll compressors, and can solve the problems of size limitation, inability to swing large scroll parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0020] [Structure of Scroll Compressor 100]

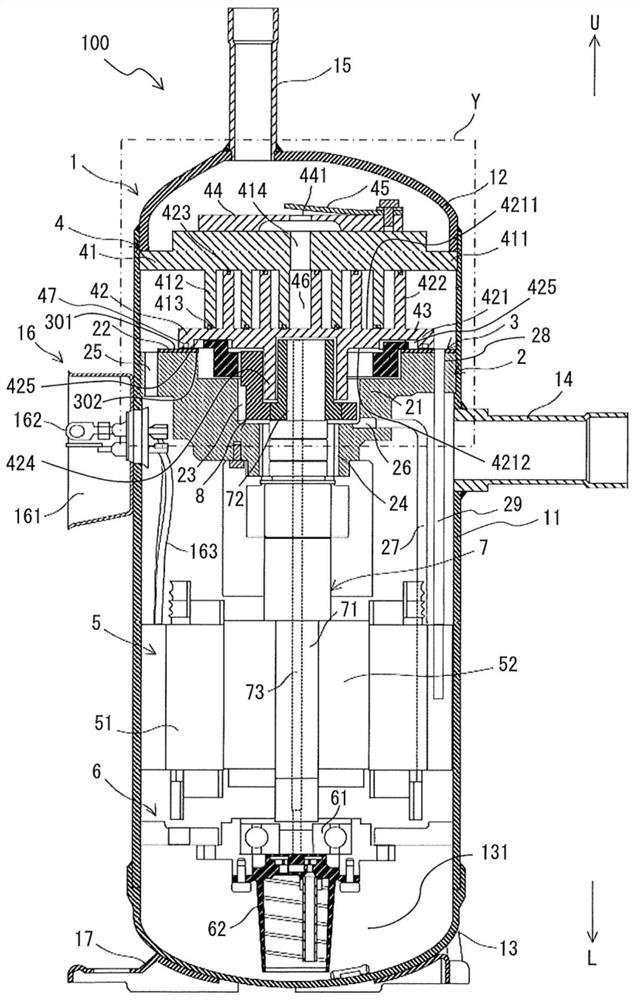

[0021] figure 1 It is a vertical cross-sectional view of scroll compressor 100 according to Embodiment 1 of the present invention. The scroll compressor 100 is applied, for example, to a refrigeration cycle device used for refrigeration or air conditioning, such as a refrigerator or a freezer, a vending machine, an air conditioner, a refrigeration device, and a water heater. The scroll compressor 100 sucks in the refrigerant circulating in the refrigeration circuit of the refrigeration cycle device, compresses it into a high-temperature and high-pressure state, and discharges it.

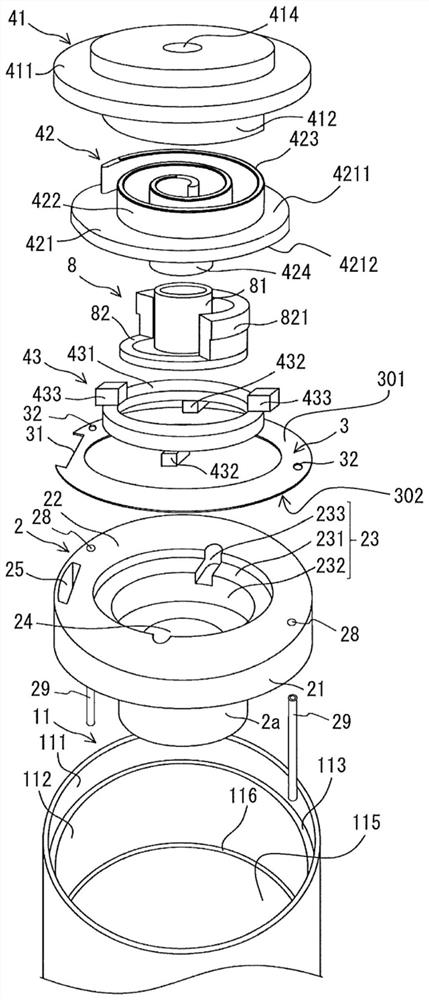

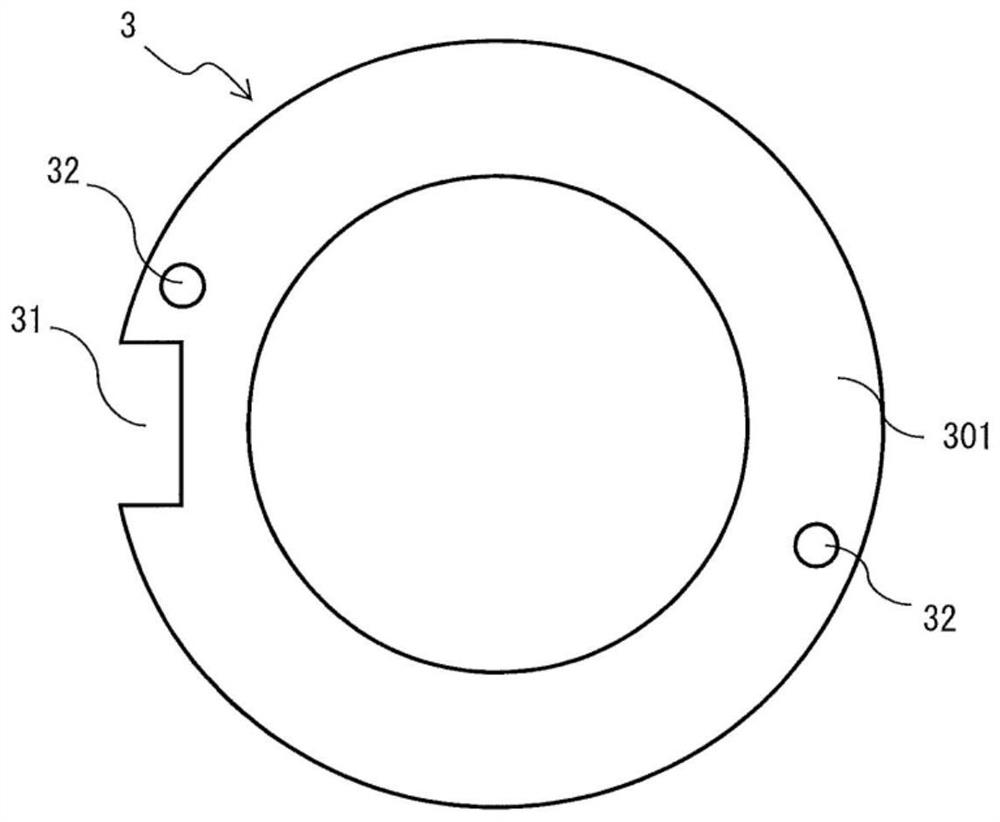

[0022] The scroll compressor 100 includes a casing 1 , a main frame 2 , a thrust plate 3 , a compression mechanism 4 , and a thrust oil return pipe 29 . In addition, the scroll compressor 100 includes a drive mechanism portion 5 , a subframe 6 , a crankshaft 7 , and a bush 8 . The scroll compressor 100 according to Embodiment 1 is used in a state wher...

Embodiment approach 2

[0108] Figure 9 It is a bottom view of the orbiting scroll 42a used in the scroll compressor 100 according to Embodiment 2 of the present invention. pair with Figure 1 to Figure 6 The parts having the same structure as those of the scroll compressor 100 are denoted by the same reference numerals, and description thereof will be omitted. In addition, items not particularly described in the swing scroll 42a are the same as those of the swing scroll 42 of the scroll compressor 100 according to Embodiment 1 of the present invention, and the same functions and structures are assigned the same reference numerals. describe.

[0109] The swing scroll 42 a is different from the swing scroll 42 of the scroll compressor 100 according to Embodiment 1 in that the oil supply groove 47 communicates with the second Oldham groove 425 . That is, the second crosshead groove 425 is formed to communicate with the oil supply groove 47 . Therefore, in the scroll compressor 100 , the lubricatin...

Embodiment approach 3

[0112] Figure 10 It is a longitudinal sectional view of the seal 49a used in the scroll compressor 100 according to Embodiment 3 of the present invention. pair with Figure 1 to Figure 6 as well as Figure 9 The parts having the same structure as those of the scroll compressor 100 are denoted by the same reference numerals, and description thereof will be omitted. In addition, items not particularly described in the seal 49a are the same as the seal 49 of the scroll compressor 100 according to Embodiment 1 of the present invention, and the same functions and structures are described using the same reference numerals.

[0113] The seal 49 a is different from the seal 49 of the scroll compressor 100 according to Embodiment 1 in that the through hole 491 is formed in the seal 49 a. The number of through-holes 491 formed in the sealing material 49a may be one or plural. The through hole 491 is formed in the radial direction of the second platen 421 in a state where the packin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com