A device for filtering and treating waste water in papermaking industry

A papermaking industry wastewater and treatment device technology, applied in the direction of filtration separation, filtration circuit, fixed filter element filter, etc., can solve the problems of different sizes of paper scraps, reduce the efficiency of filtration mechanism for wastewater filtration, and blockage of filter holes, etc. Achieve the effect of improving the filtration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

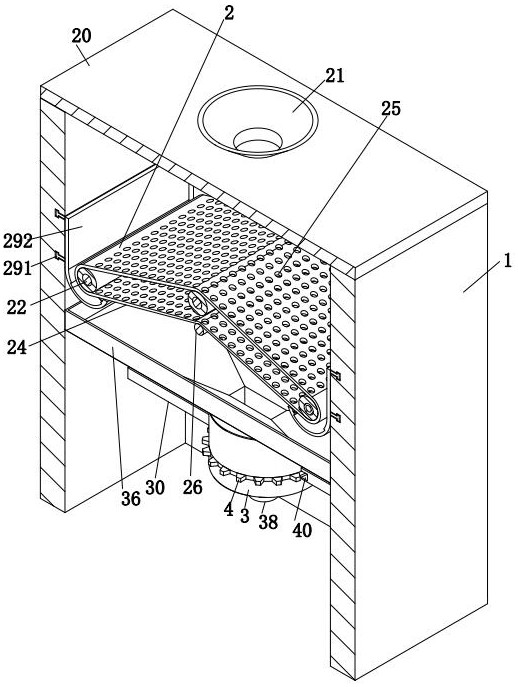

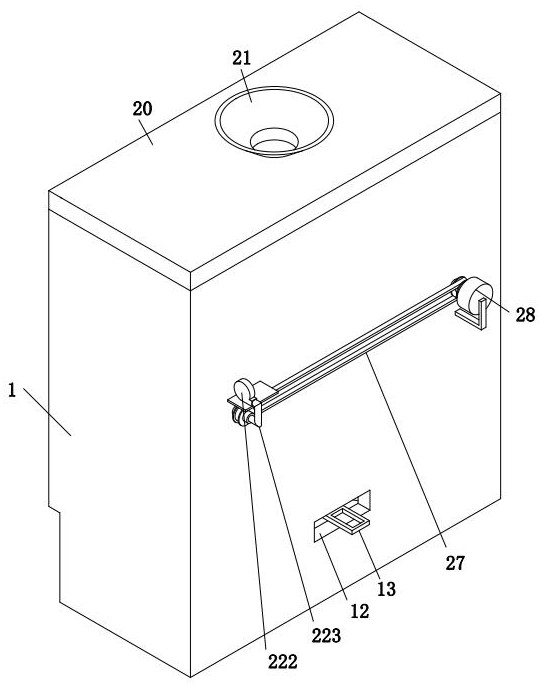

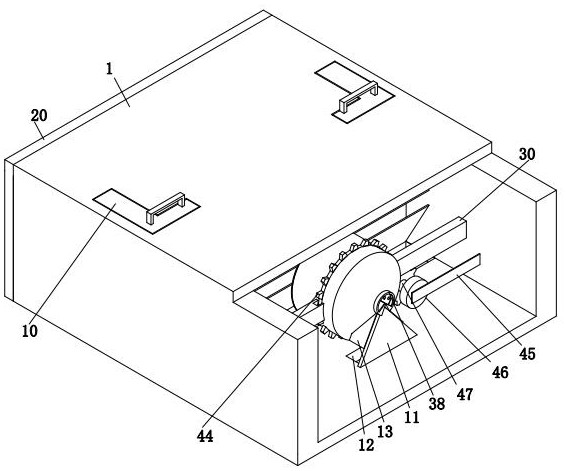

[0032] refer to figure 1 , a kind of wastewater treatment device for papermaking industry, comprising a treatment box 1, a primary filter mechanism 2, a secondary filter mechanism 3 and a scraping mechanism 4, the treatment box 1 is a back-shaped structure with openings at the upper and lower ends, and the treatment box The inner wall of 1 is sequentially provided with a primary filter mechanism 2 and a secondary filter mechanism 3 from top to bottom, and a scraper mechanism 4 is provided on the secondary filter mechanism 3 .

[0033] refer to figure 1 , figure 2 and Figure 5 , the primary filter mechanism 2 includes a top cover 20, a feed hopper 21, a rotating shaft 22, a conveying roller 23, a conveyor belt 24, a coarse filter hole 25, a suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com