Method for installing rolling mill pressure cylinder in limited space

A technology with a limited space and an installation method, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of difficulty in installing the rolling mill and pressing the upper cylinder, and achieve the effect of safe and stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

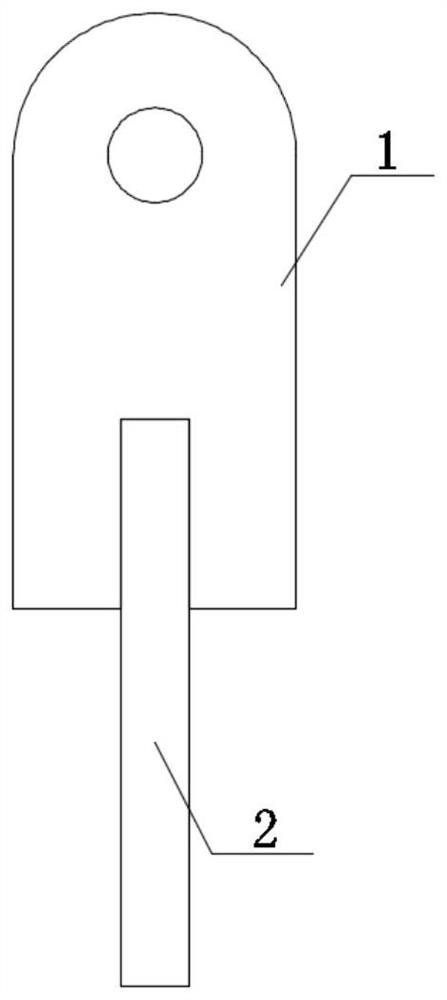

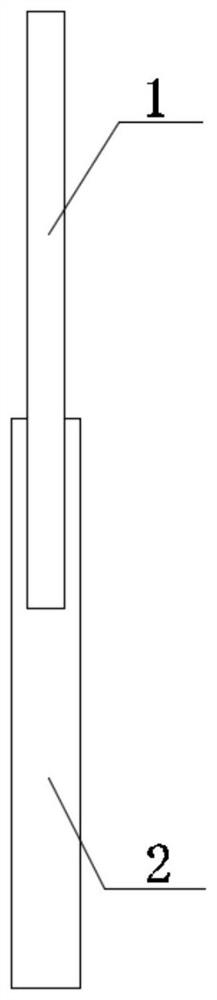

[0043] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

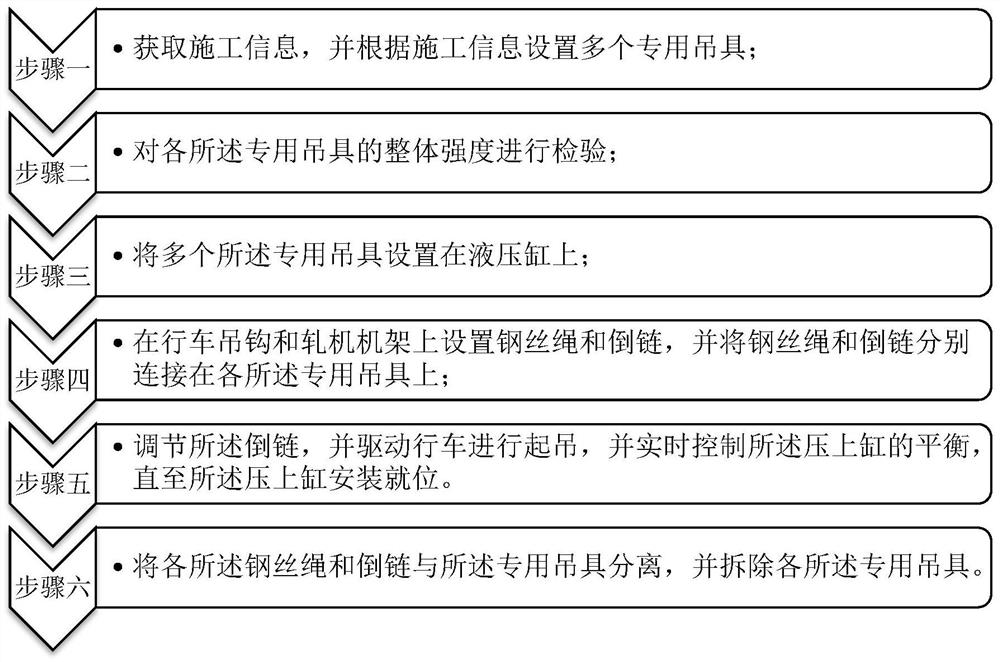

[0044] refer to Figure 1 to Figure 5 , the application provides a method for installing the upper cylinder of a rolling mill in a confined space, comprising: Step 1, obtaining construction information, and setting a plurality of special spreaders according to the construction information; Step 2, checking the overall strength of each of the special spreaders Carry out inspection; Step 3, a plurality of said special spreaders are arranged on hydraulic cylinder; On the special spreader; Step 5, adjust the chain down, and drive the crane to lift, and control the balance of the pressing cylinder 3 in real time until the pressing cylinder 3 is installed in place. Step 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com