Steel column manhole structure and mounting method thereof

A technology of hole structure and steel column, applied in the direction of structural elements, building components, building structure, etc., can solve the problems of inconvenient on-site installation, welding positioning, cumbersome, and unfavorable for project cost control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

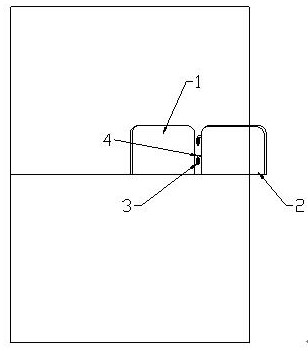

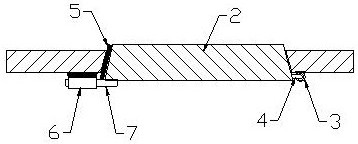

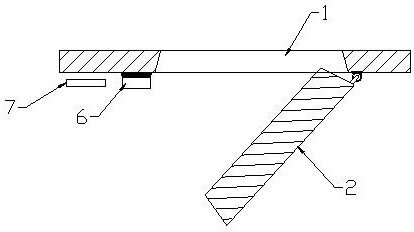

[0023] see Figure 1 to Figure 3 Shown, the installation structure of the manhole plate that the present invention designs, adopts the surplus material waste material in the construction, the steel bar sleeve and the steel bar head are made the combination of the sleeve 3 of segment and round pin 4. The round pin 4 rotates in the sleeve 3, thereby constituting the installation axis of the manhole plate. Specifically, both sides of the manhole plate 2 are cut into slopes; the right side of the manhole plate 2 is fixed to the round pin 4, the round pin 4 is installed in the sleeve 3, and the sleeve 3 is fixed to the right side of the steel column manhole 1; The left edge of the steel column manhole 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com