Fork frame vertical plate type bridge expansion joint connecting device

A technology for connecting devices and expansion joints, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as increased cost, corrosion, and upper and lower deformation of the main steel plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

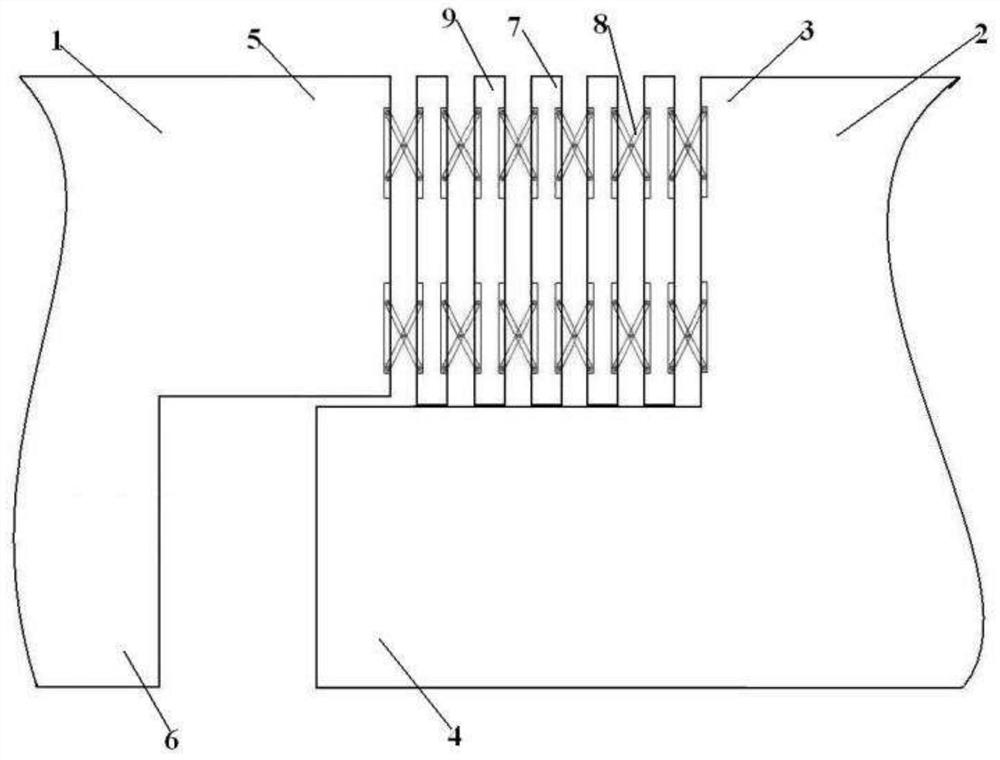

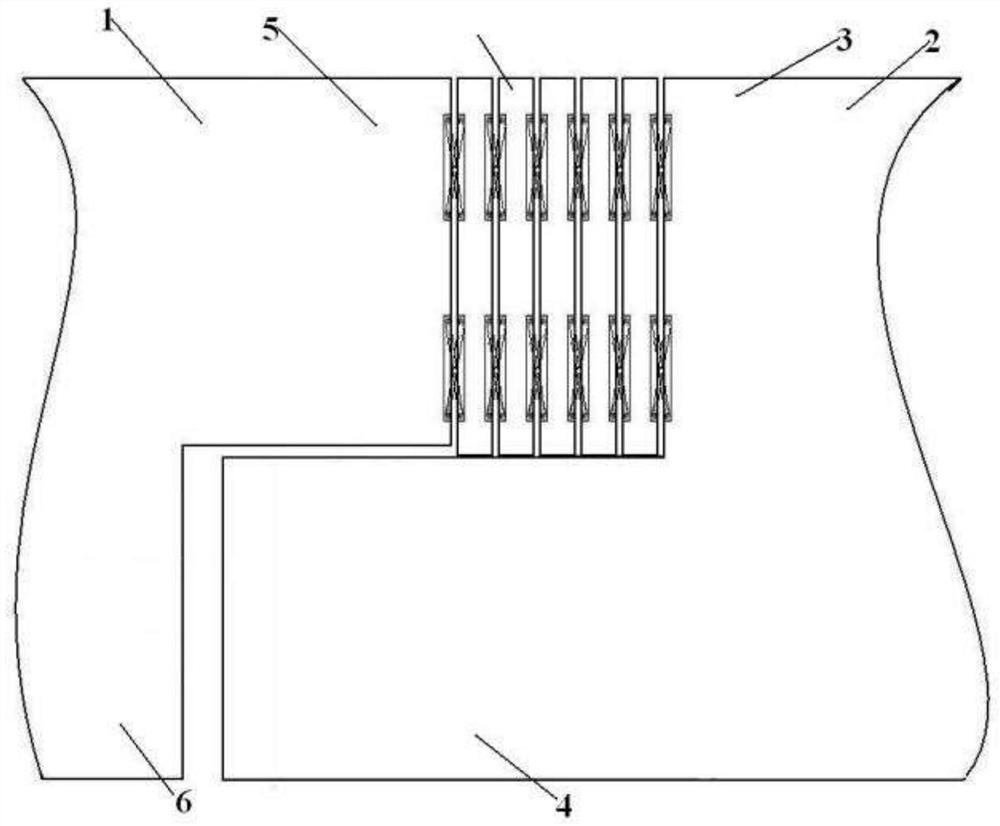

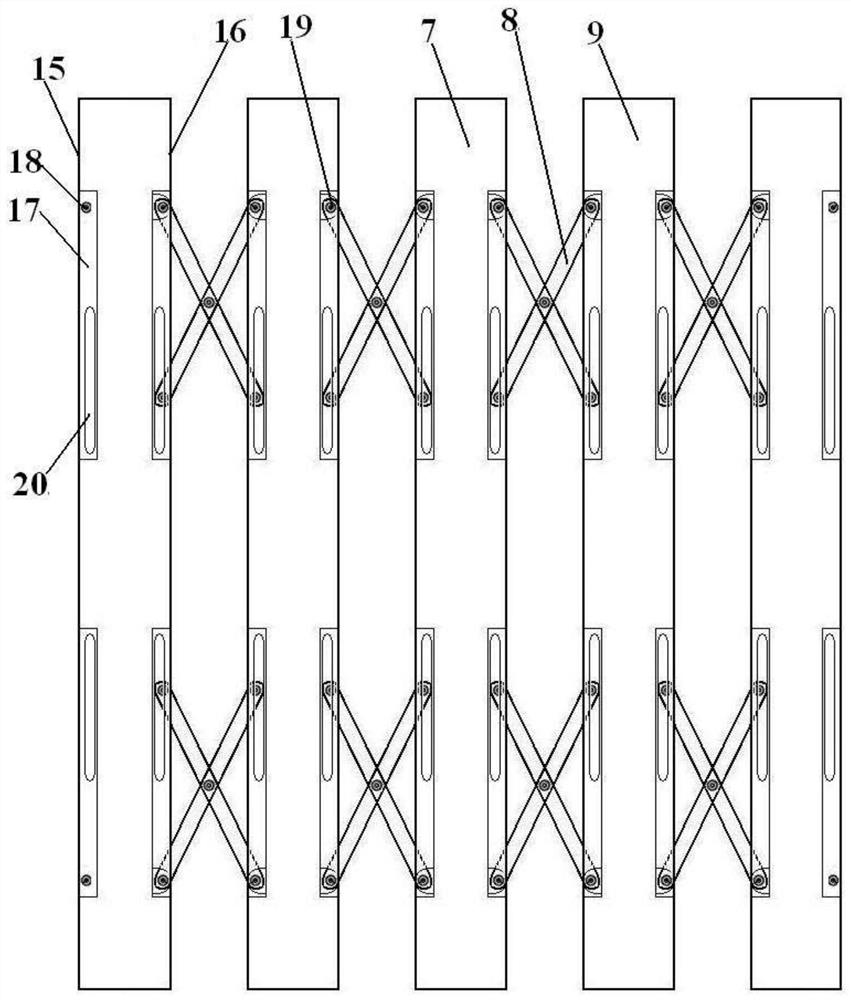

[0044] As shown in the figure, a fork vertical plate type bridge expansion joint connection device is made, including the left bridge body 1 and the right bridge body 2 that form the expansion joint, and the side of the expansion joint of the right bridge body 2 is a double-stage ladder that is placed upright structure, the two-stage ladder is called the right side body 3 and the platform body 4 respectively, the right side body 3 is generated above the platform body 4 and dislocated to the right; the side of the expansion joint of the left bridge body 1 is an inverted double-stage Ladder structure, the two-stage ladder is respectively called the left body 5 and the pituitary body 6, and the pituitary body 6 is generated under the left body body 5 and dislocated to the left; the pituitary body 6 is correspondingly isolated from the platform body 4, and the left side body 6 The side body 5 is suspended on the platform body 4 and is correspondingly isolated from the right side bo...

Embodiment 2

[0053] On the basis of Embodiment 1, a cover plate 27 is also provided above the left bridge body 1 and the right bridge body 2, and the cover plate 27 includes a flat plate portion 28 and an acute angle plate portion 29, wherein the flat plate portion 28 is located in the middle of the cover plate 27, and the flat plate portion 28 is a flat plate whose upper and lower surfaces are parallel to each other. The acute angle plate portion 29 is located on both sides of the flat plate portion 28 on the cover plate 27. The upper surface is inclined and intersects the acute angle plate with the lower surface; the flat part 28 of the cover plate 27 completely covers the several fork vertical plate chains 7 fixedly connected to the left side body 1 and the right side body 2 .

[0054] Further, the upper surfaces of the left bridge body 1 and the right bridge body 2 are respectively directly formed with first wave-shaped connecting grooves 30 protruding from the surface on the upper surf...

Embodiment 3

[0056] The construction method of the fork vertical plate type bridge expansion joint connection device includes the following steps:

[0057] (1) To make the bridge expansion joint partition surface, the sections of the left bridge body 1 and the right bridge body 2 constituting the expansion joints are both made into a double-stage ladder structure, wherein the expansion joint section of the left bridge body 1 is made into an inverted double-stage ladder structure, the two-stage ladder is called the left side body 5 and the pituitary body 6 respectively, and the pituitary body 6 is generated under the left side body 5 and dislocated to the left; the expansion joint section of the right bridge body 2 is made into an upright double The double-stage ladder is called the right side body 3 and the platform body 4 respectively, and the right side body 3 is generated above the platform body 4 and dislocated to the right; at the same time, the pituitary body 6 is corresponding to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com