Method for detecting the position of a mobile switching element

A technology for shifting components and equipment, applied in the direction of mechanical equipment, components with teeth, transmission control, etc., can solve complex and other problems, and achieve the effects of reliable identification, simple electronic evaluation, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

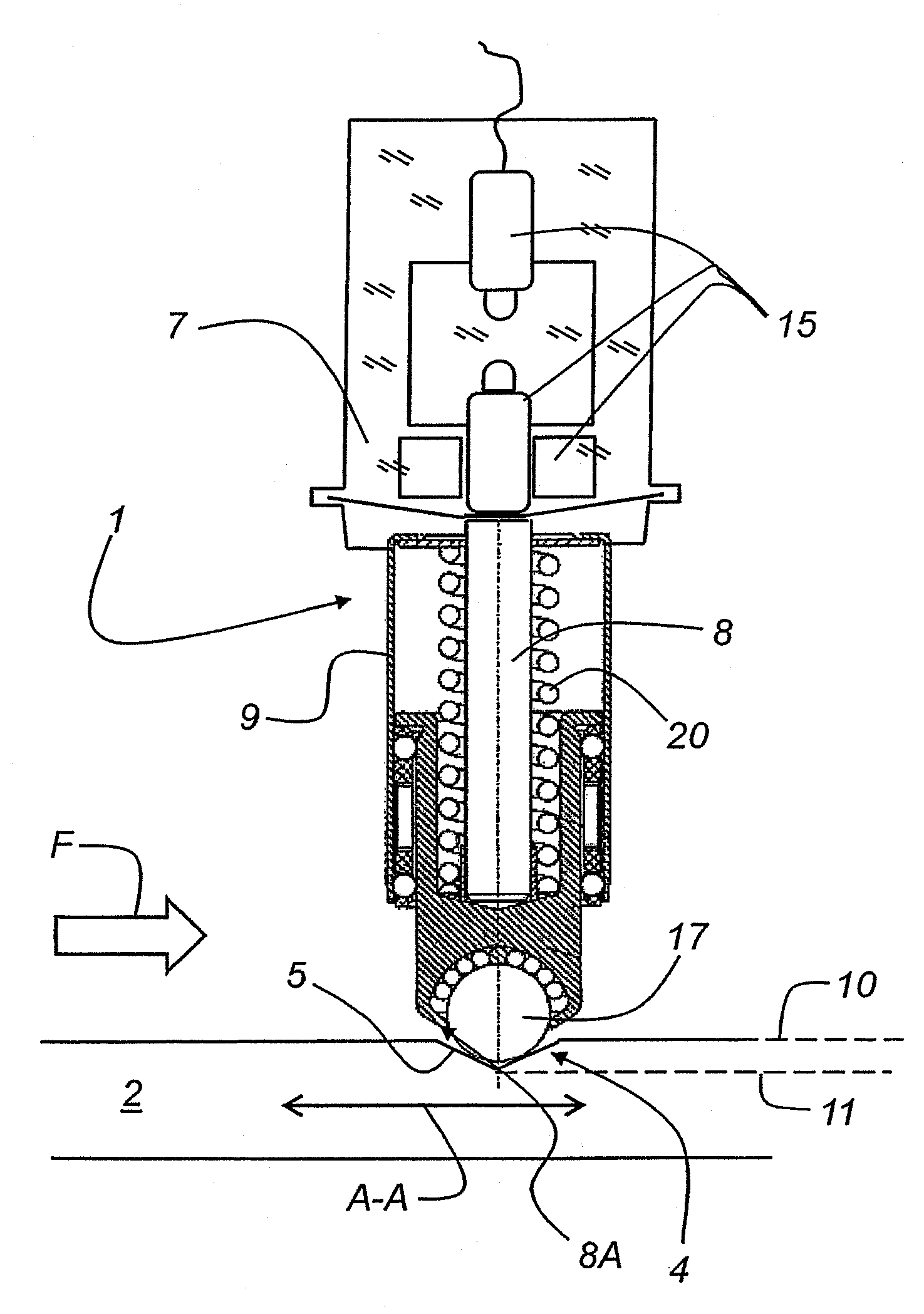

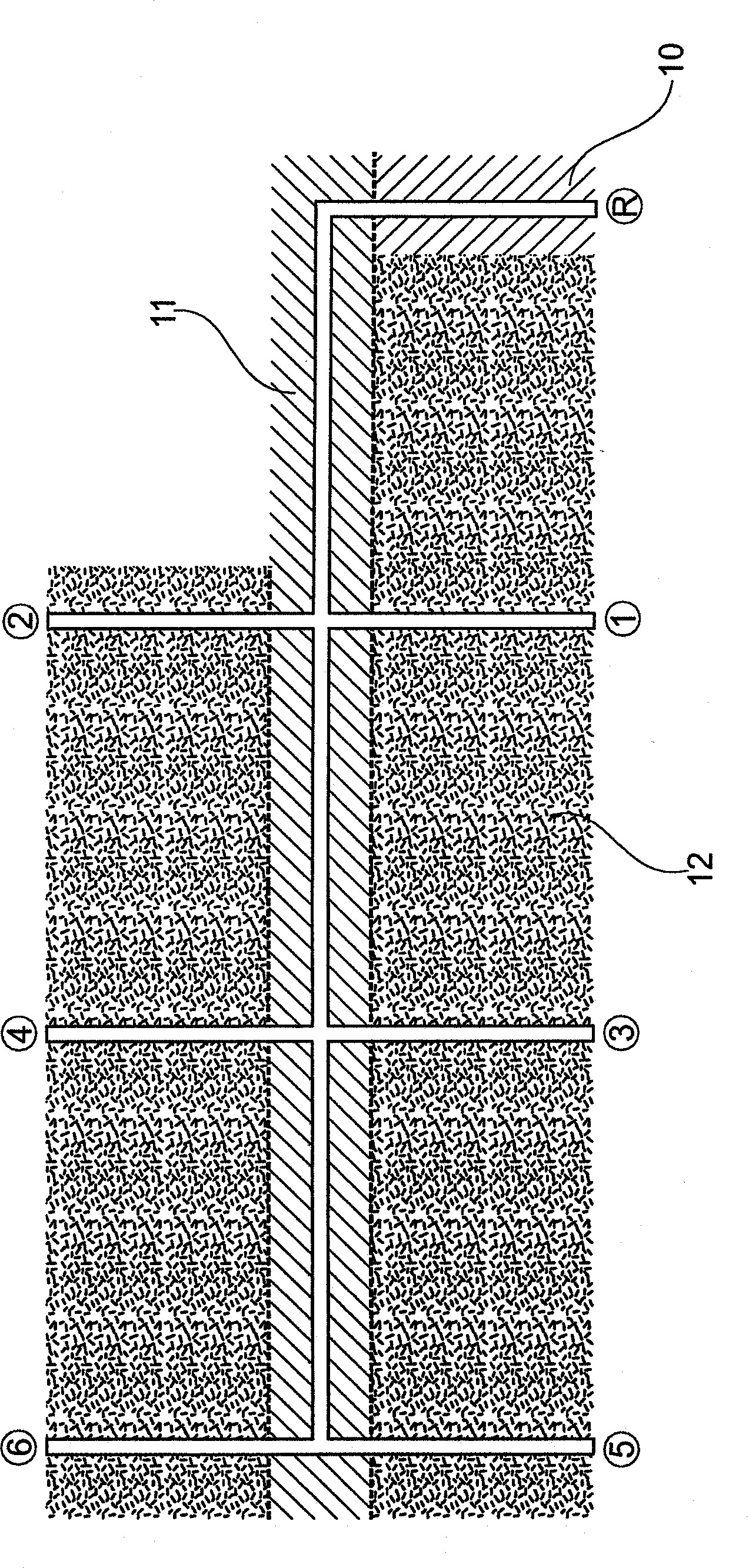

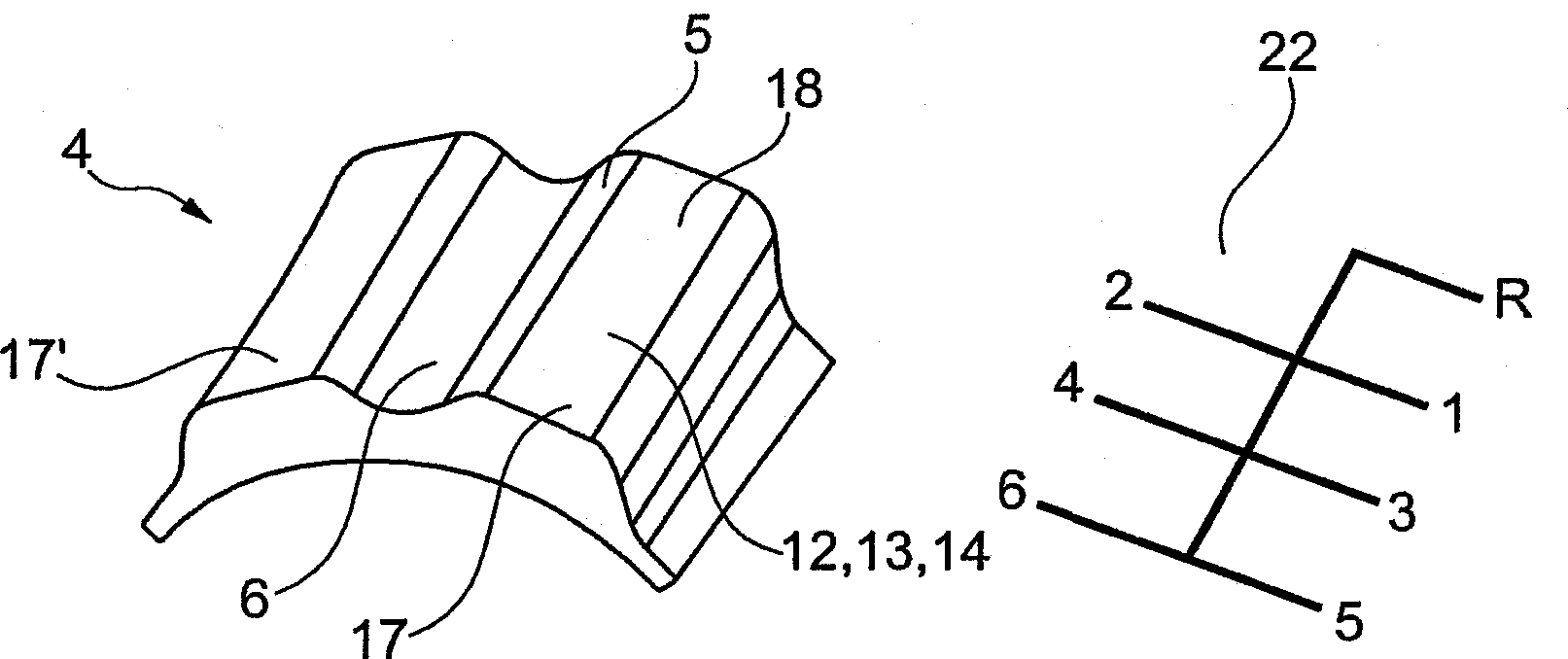

[0026] figure 1 A schematic diagram of a device 1 for detecting the position of a movable shifting or adjusting element 2 is shown. Shift or adjustment element 2 along the figure 1 Movement in the direction of movement shown by the double arrow A-A. The shifting or adjusting element has at least one stop 4 configured with a corresponding contour 5 . A device 1 for detecting the position of a movable shifting or adjusting element 2 is assigned to the shifting or adjusting element. The device 1 has a liftable pushbutton element 8 which carries a ball 17 on a front end 8A of the pushbutton element. The ball 17 engages in the contour 5 of the shifting or adjusting element 2 in a corresponding manner. The induction bolt 8 is pretensioned by means of a spring 20 . The induction bolt 8 itself moves inside the housing 9 . The posture of the sensing bolt 8 is detected by the sensor button 7 . For this purpose, the sensor button 7 includes a plurality of sensors 15 . The profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com