A method for measuring sulfur content in dolomite

A technology for dolomite and sulfur content, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of difficult release, low test accuracy, and low sulfur measurement value, and achieve high measurement value and test accuracy High and precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

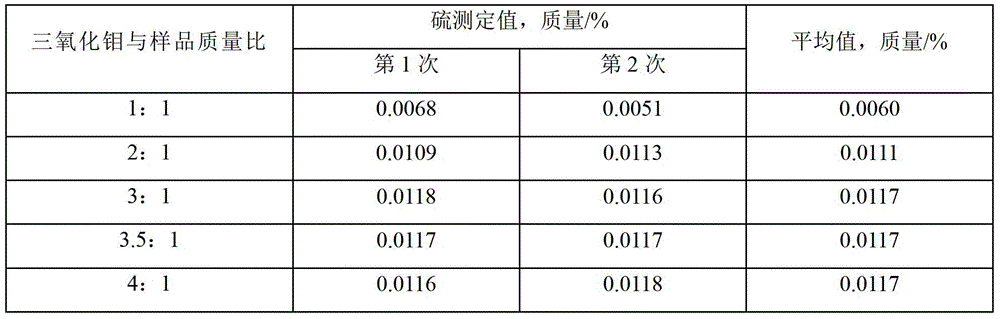

[0026] Weigh the dolomite sample (sample A) to be tested with an electronic balance, and place it in a carbon-sulfur ceramic crucible, add different masses of molybdenum trioxide powder (melting point: 795°C), and use a fine wire to Mix the dolomite sample with molybdenum trioxide evenly, and then add metal tungsten particles fixedly, the mass ratio of metal tungsten particles to dolomite sample is 10:1. Cover the ceramic crucible; then place the carbon-sulfur ceramic crucible on a high-frequency infrared carbon-sulfur meter (Germany ELTRA company, model: CS2000) to measure the sulfur content, operate according to the instrument manual, and measure A dolomite sample twice in parallel , the measurement results are shown in Table 1.

[0027] Table 1

[0028]

[0029] It can be seen from Table 1 that when the mass ratio of molybdenum trioxide to sample is 3-4:1, the determination results are stable.

Embodiment 2

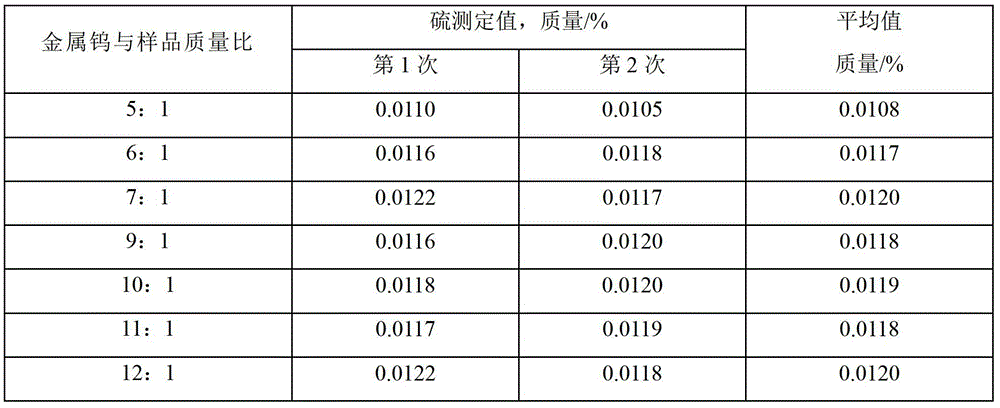

[0031] Weigh the dolomite sample to be tested (sample A) with an electronic balance, accurate to 0.1 mg, place it in a carbon-sulfur ceramic crucible, add molybdenum trioxide powder (melting point: 795°C), and control the mass ratio of molybdenum trioxide powder to sample at 3:1. Mix the dolomite sample to be tested with molybdenum trioxide evenly with a thin wire, then add metal tungsten particles of different qualities, and cover the ceramic crucible; then place the carbon-sulfur ceramic crucible in a high-frequency infrared carbon-sulfur analyzer (Germany ELTRA , model: CS2000) for the determination of sulfur content, according to the instrument manual, parallel measurement of A dolomite sample twice, the results are shown in Table 2.

[0032] Table 2

[0033]

[0034] It can be seen from Table 2 that when the mass ratio of metal tungsten particles to samples is 6-12:1, the results are stable.

Embodiment 3

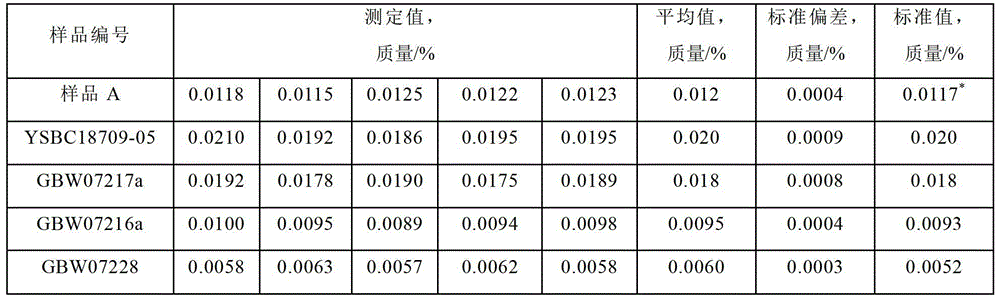

[0036]Weigh the dolomite sample to be tested with an electronic balance, accurate to 0.1mg, place it in a carbon-sulfur ceramic crucible, add molybdenum trioxide powder (melting point: 795°C), and control the mass ratio of molybdenum trioxide to dolomite sample at 3:1 . Mix the dolomite sample to be tested with molybdenum trioxide evenly with a thin wire, and then add metal tungsten particles, the mass ratio of metal tungsten particles to dolomite sample is 10:1. Cover the ceramic crucible; then place the carbon-sulfur ceramic crucible on a high-frequency infrared carbon-sulfur analyzer (ELTRA, Germany, model: CS2000) to measure the sulfur content, and operate according to the instrument manual. First measure the sulfur content of YSB14749-96 dolomite chemical analysis standard sample, measure 3 times, calibrate the correction coefficient of sulfur in the high-frequency infrared carbon-sulfur meter instrument with the measured value obtained 3 times, and then measure the dolom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com