Detection method of room-temperature compressive property of continuous fiber-reinforced ceramic-based composite material

A continuous fiber and composite material technology, which is applied in the direction of strength characteristics, material analysis, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problem of huge differences in fiber weaving direction performance, inability to distinguish main directions, and large errors in test results, etc. problems, to achieve the effect of high accuracy of measured values, convenient processing, and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

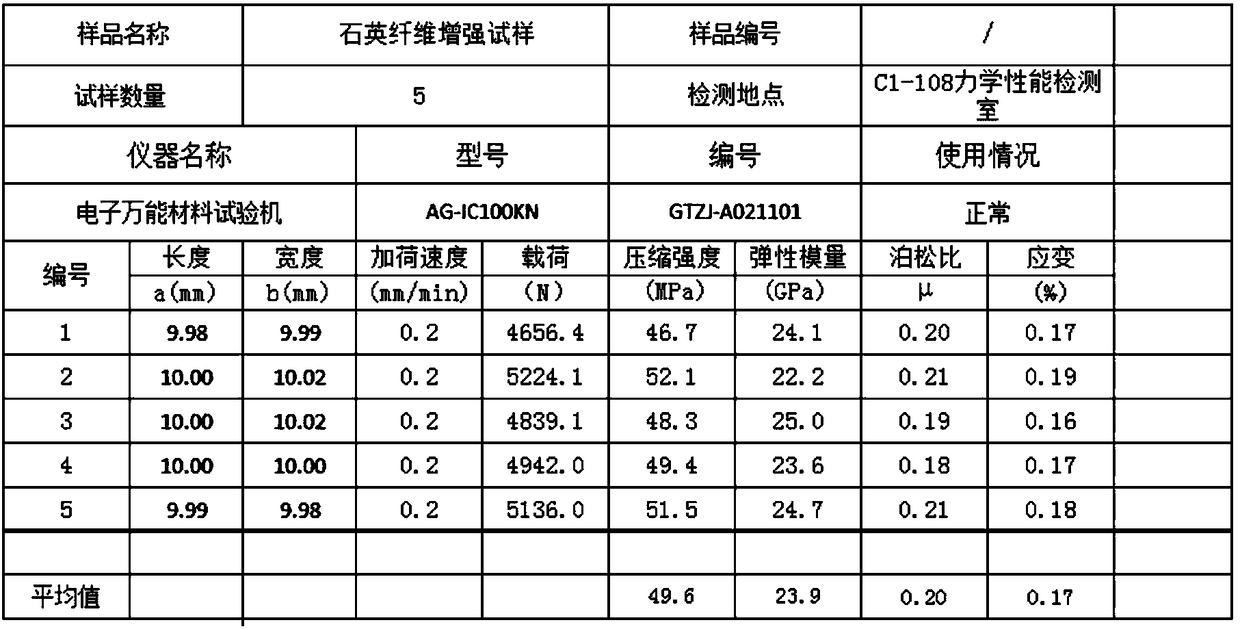

[0025] This embodiment provides a method for detecting the room-temperature compression performance of continuous fiber-reinforced ceramic matrix composites, including the following steps:

[0026] S1. Determine the cutting direction when sampling according to the weaving direction of the fiber reinforcement of the continuous fiber-reinforced ceramic matrix composite material, and cut and process the continuous fiber-reinforced ceramic matrix composite material to obtain a sample. The sample is cylindrical or cuboid, cylindrical Dimensions of a rectangular sample diameter × height = 10 (± 0.2) mm × 25 (± 0.5) mm, dimensions of a cuboid sample length × width × thickness = 10 (± 0.2) mm × 10 (± 0.2) mm × 25 (± 0.2) mm 0.5)mm, parallelism and perpendicularity are ≤0.01mm.

[0027] When preparing samples, cut them in strict accordance with the main directions of continuous fiber-reinforced ceramic composites (such as axial, radial, normal, etc.), and the fiber direction and layup ...

Embodiment 2

[0063] This embodiment provides a method for detecting the room-temperature compression performance of continuous fiber-reinforced ceramic matrix composites, including the following steps:

[0064] S1. Determine the cutting direction when sampling according to the weaving direction of the fiber reinforcement of the continuous fiber-reinforced ceramic matrix composite material, and cut and process the continuous fiber-reinforced ceramic matrix composite material to obtain a sample. The sample is cylindrical or cuboid, cylindrical The size of the sample is diameter × height = 10mm × 25mm, the size of the cuboid sample is length × width × thickness = 10mm × 10mm × 25mm, and the parallelism and perpendicularity are both 0.01mm.

[0065] When preparing samples, cut them in strict accordance with the main directions of continuous fiber-reinforced ceramic composites (such as axial, radial, normal, etc.), and the fiber direction and layup direction are consistent with the test requirem...

Embodiment 3

[0101] This embodiment provides a method for detecting the room-temperature compression performance of continuous fiber-reinforced ceramic matrix composites, including the following steps:

[0102] S1. Determine the cutting direction when sampling according to the weaving direction of the fiber reinforcement of the continuous fiber-reinforced ceramic matrix composite material, and cut and process the continuous fiber-reinforced ceramic matrix composite material to obtain a sample. The sample is cylindrical or cuboid, cylindrical Dimensions of rectangular parallelepiped sample diameter × height = 10.2mm × 24.5mm, length × width × thickness of cuboid specimen = 10.2mm × 9.8mm × 24.5mm, parallelism and perpendicularity are ≤0.01mm.

[0103] When preparing samples, cut them in strict accordance with the main directions of continuous fiber-reinforced ceramic composites (such as axial, radial, normal, etc.), and the fiber direction and layup direction are consistent with the test req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com