Real vehicle function safety fault injection test method and system

A technology of fault injection and functional safety, which is applied in the direction of test/monitoring control system, general control system, electrical test/monitoring, etc. It is difficult to grasp, save a lot of work, and realize the effect of on-off control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

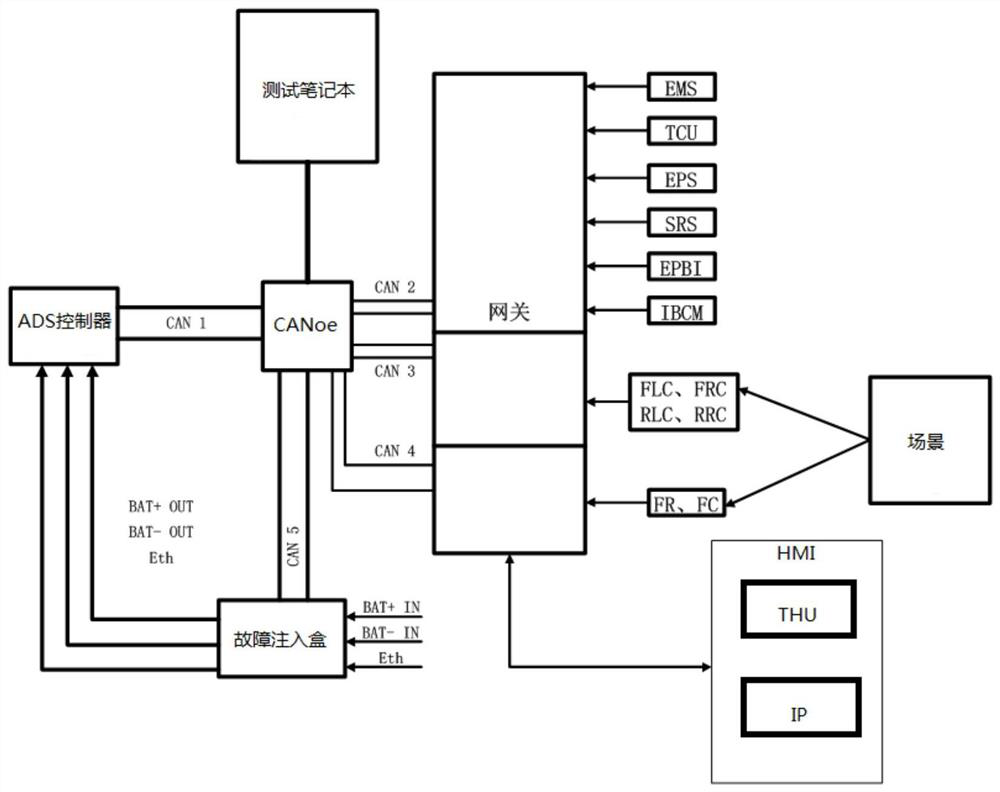

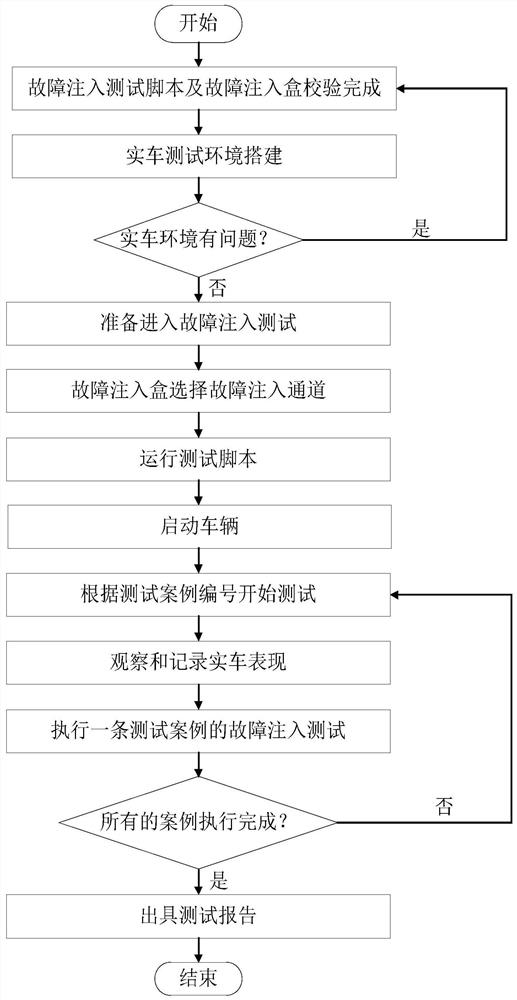

Method used

Image

Examples

test Embodiment ID

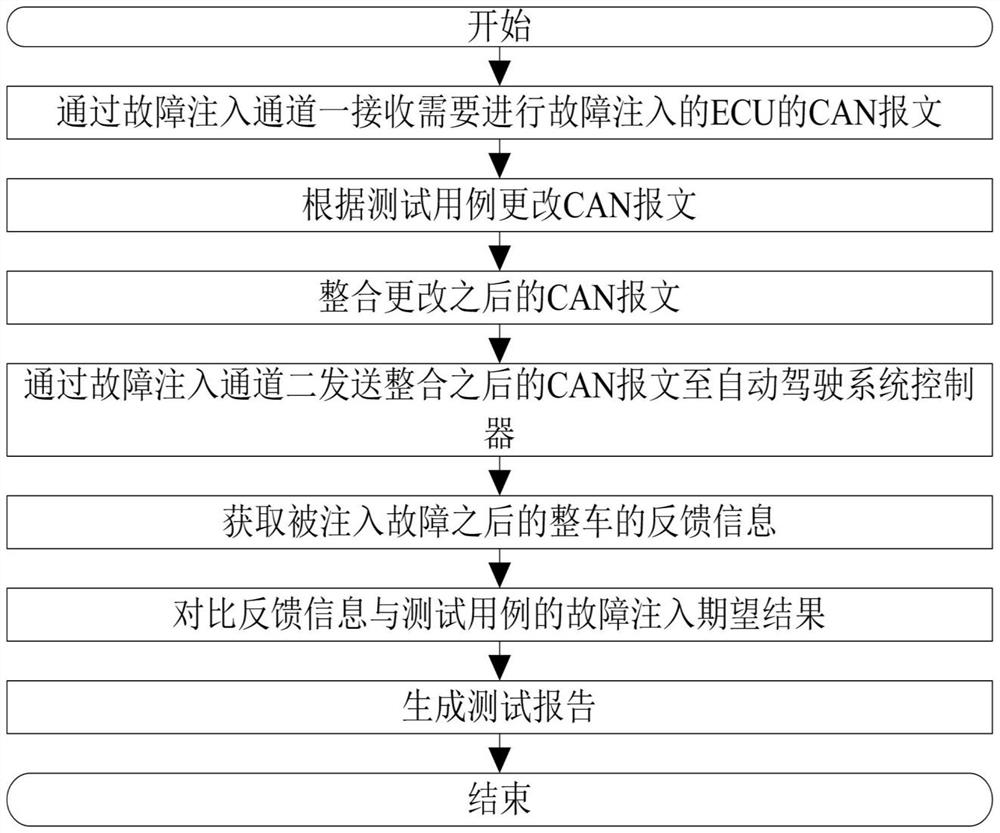

[0028] see image 3 , the present invention provides a kind of actual vehicle functional safety fault injection test method, obtains test case according to the test case ID to be tested, judges whether the fault injection condition of real vehicle meets the requirement, if so, then enters the test stage, and test method specifically comprises the following steps:

[0029] Step A: Receive the CAN message of the ECU that needs fault injection through channel one;

[0030] Step B: Change the CAN message according to the test case;

[0031] Step C: Integrate the changed CAN message;

[0032] Step D: sending the integrated CAN message of step C through channel 2;

[0033] Step E: Obtain the feedback information of the vehicle after the fault is injected, wherein the vehicle after the fault is injected is the vehicle that has received the integrated CAN message in step D;

[0034] Step F: Compare the feedback information with the expected result of fault injection of the test cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com