A method for reducing the eccentric torsional stiffness of a multi-layer rod-end ball joint and a multi-layer rod-end ball joint

A technology of torsional stiffness and ball joints, applied in shafts and bearings, non-rotational vibration suppression, pivots, etc., to achieve the effects of reducing torsional stiffness, ensuring radial stiffness, and increasing stress release space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

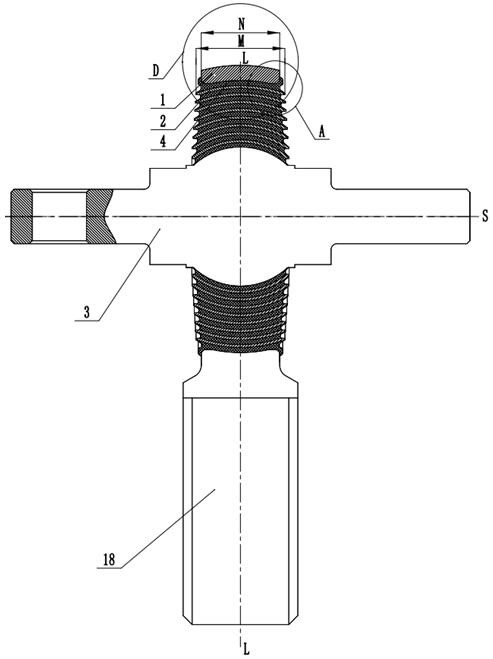

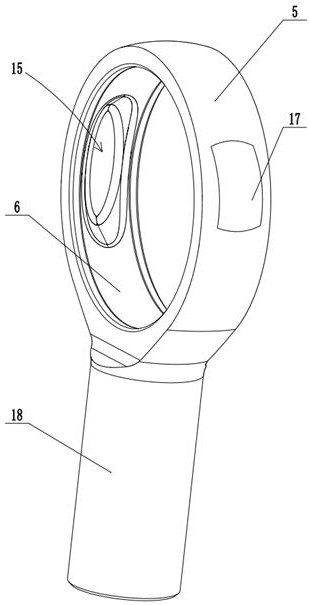

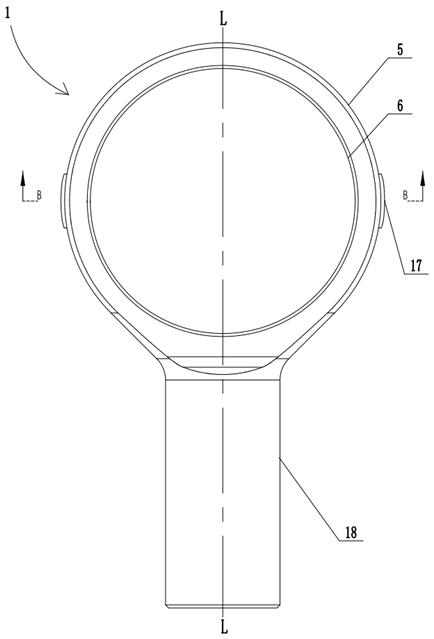

[0030] This example Figure 1-6 As shown, a method to reduce the eccentric torsional stiffness of the multi-layer rod end ball joint, such as figure 1 As shown, the above-mentioned rod end ball joint includes a casing 1, a mandrel 3 and a rubber layer. The threaded handle 18 is provided on the casing 1 to facilitate the use and operation of the rod end ball joint; the rubber layer is located between the casing 1 and the mandrel 3, There are multi-layer spacers inside the rubber layer, and the multi-layer spacers divide the rubber layer into multiple layers. The layer of spacers adjacent to the jacket 1 is the outermost spacer 2, and the space between the outermost spacer 2 and the jacket 1 The rubber layer is the outermost rubber 4; as figure 2 As shown, the jacket 1 includes a jacket outer peripheral surface 5 and an outer jacket inner peripheral surface 6. A groove 15 is provided inside the outer jacket inner peripheral surface 6 and rubber is vulcanized in the groove 15. ...

Embodiment 2

[0036] as attached Figure 7 As shown, the difference between this embodiment and the first embodiment is that several narrow and long small grooves 16 are arranged at the groove bottom of the curved surface groove 15. The groove 16 further increases the bonding area between the outermost spacer 2 and the outermost spacer 1 to prevent the outermost layer of rubber 4 from peeling off between the outermost layer 1 and the outermost spacer 2 when the ball joint bears a large torsional load.

[0037] The present invention also provides a multi-layer rod-end ball joint for reducing the partial torsional stiffness of the multi-layer rod-end ball joint, which includes a casing 1, a mandrel 3 and a rubber layer located between the casing 1 and the mandrel 3, and the rubber layer is provided with There are multiple layers of spacers, and the layer of spacers adjacent to the coat 1 is the outermost spacer 2; the coat 1 includes the outer peripheral surface 5 and the inner peripheral sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com