High-efficiency rubber production line capable of producing two cables at one time

A production line and high-efficiency technology, which is applied to household components, household appliances, and other household appliances, can solve problems such as waste of water resources, uneven cooling of cables, etc., achieve high production efficiency, improve cooling efficiency and quality, and be fast and effective The effect of vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

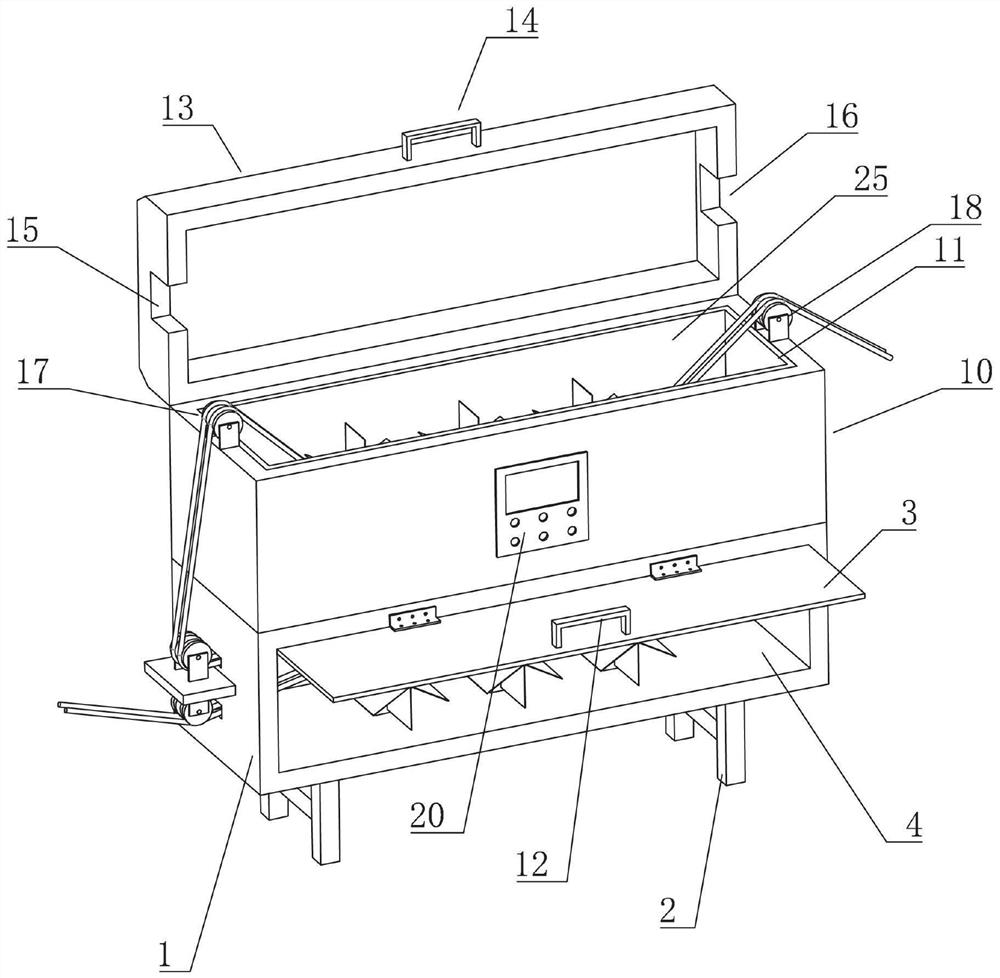

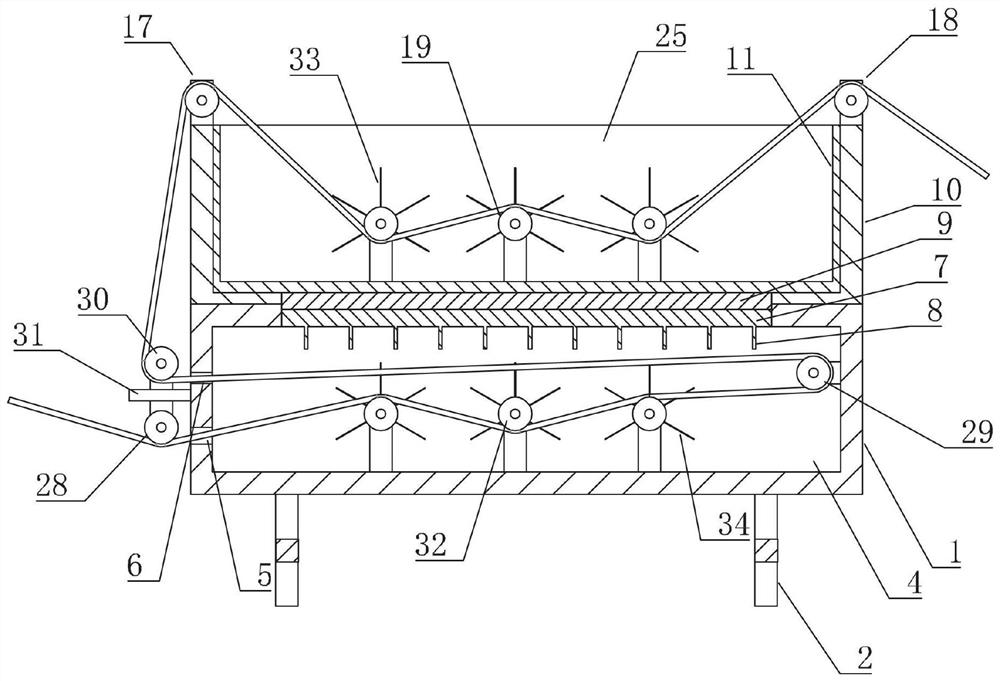

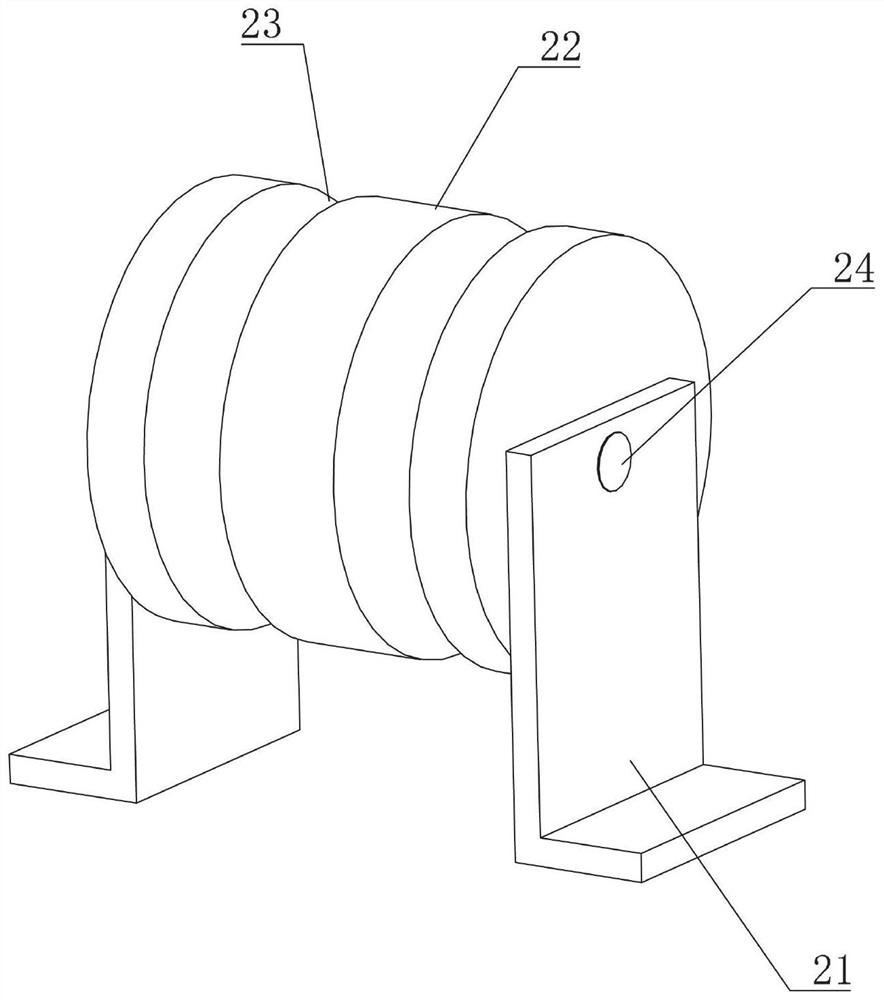

[0034] Embodiment: A high-efficiency rubber production line with one out of two, including a vulcanization device, a cooling device, and a semiconductor refrigeration chip 9, the cooling device is fixedly installed on the top of the vulcanization device, and the semiconductor refrigeration chip 9 is fixedly installed in the middle of the vulcanization device and the cooling device. The refrigerating sheet 9 is connected with direct current, so that the semiconductor refrigerating sheet 9 can heat on one side and cool on the other side.

[0035] The vulcanization device includes a vulcanization box 1 and two support frames 2 fixedly installed at the bottom of the vulcanization box 1. The vulcanization box 1 is hollow inside and has an open front side structure. The open end of the vulcanization box 1 is hinged with a first cover 3. A cover body 3 can cover the open end of the vulcanization box 1, and the first handle 12 is fixedly installed on the first cover body 3. The vulcani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com