Component pin tin plating equipment for electronic product production

A technology for electronic products and tin-plating equipment, applied in metal material coating process, coating and other directions, can solve problems such as cumbersome operation, and achieve the effect of improving work efficiency, avoiding movement, and having a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

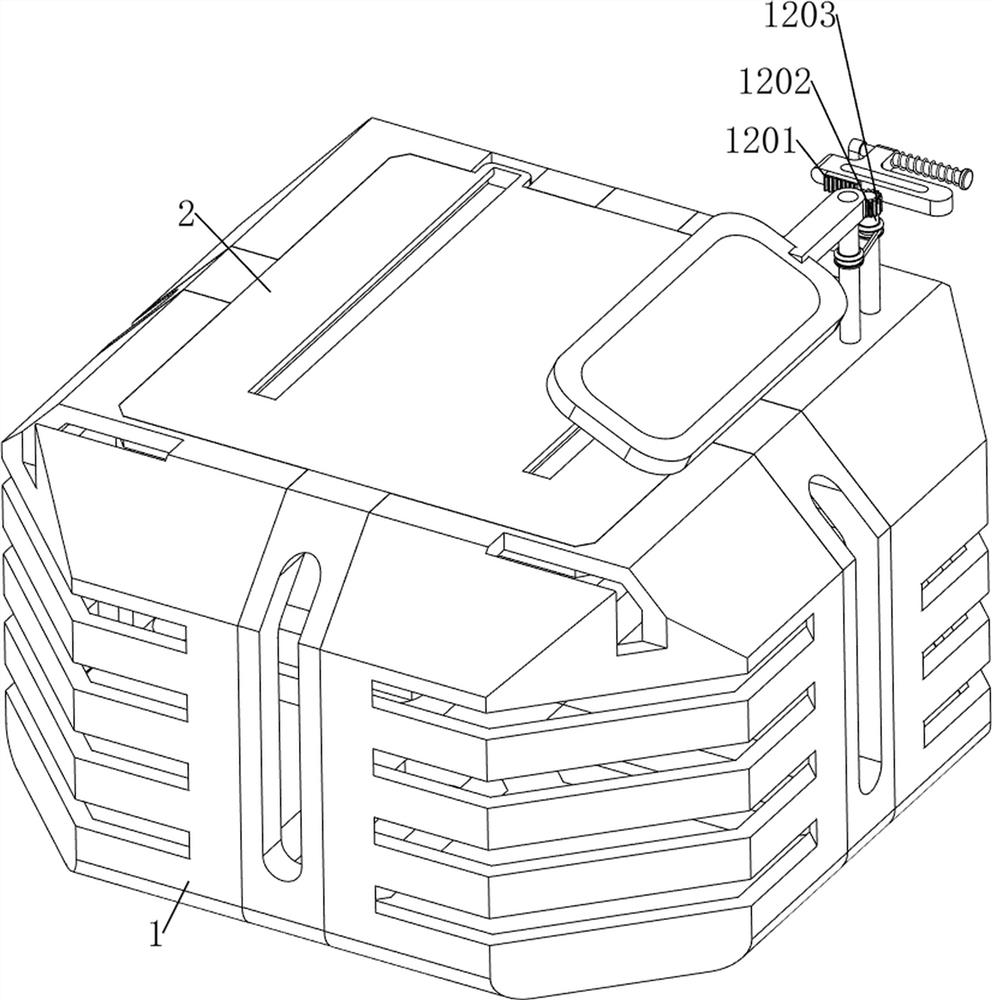

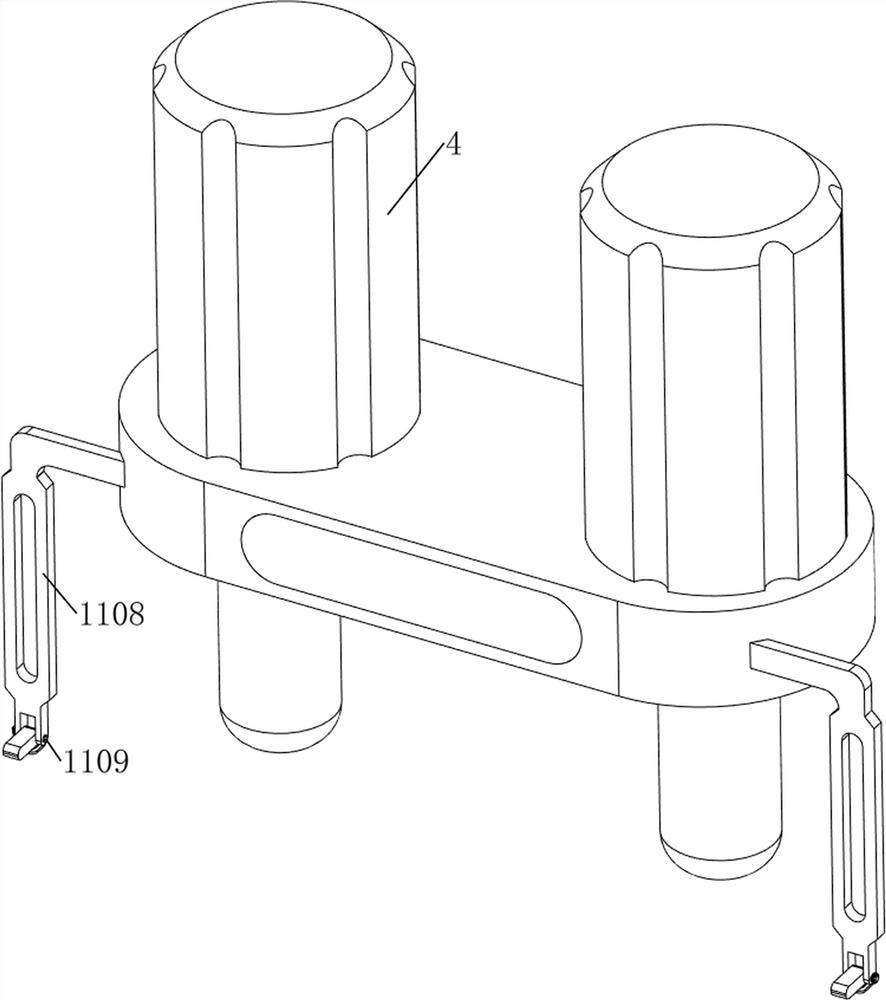

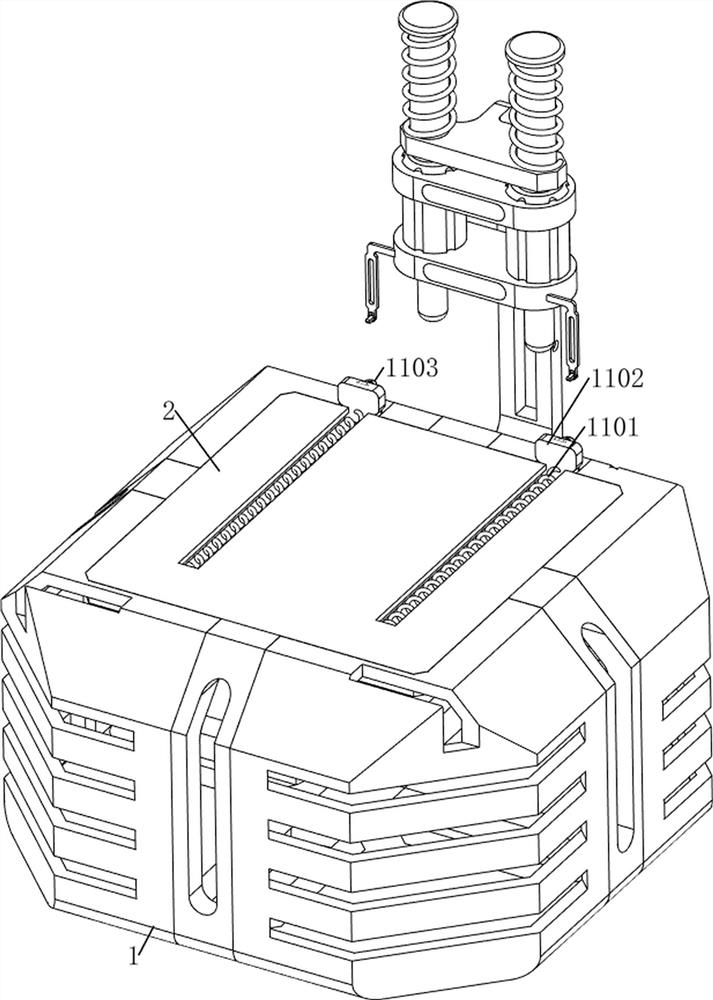

[0093] A tinning equipment for component pins used in the production of electronic products, such as Figure 1-Figure 7 As shown, it includes a casing 1, a first fixed plate 2, a first support plate 3, a tinning gun 4, a first movable rod 5, a first spring 6, a moving mechanism 7, a rotating mechanism 8 and a limit mechanism 9, the casing 1 There is a first fixed plate 2 in the middle of the top, a first support plate 3 is provided on the upper rear side of the housing 1, a first movable rod 5 is provided on the front side of the upper part of the first support plate 3, and the first movable rod 5 is symmetrically slid left and right, and the bottom of the first movable rod 5 Both are equipped with tinning guns 4, first springs 6 are arranged between the upper part of the first movable rod 5 and the first support plate 3, a moving mechanism 7 is provided on the upper right side of the inner rear part of the shell 1, and the lower part of the first support plate 3 A rotation me...

Embodiment 2

[0099] On the basis of Example 1, such as figure 1 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 and Figure 16 Shown, also comprise fixed mechanism 10, fixed mechanism 10 comprises the 6th support plate 101, inclined block 102, second fixed plate 103, guide bar 104, second spring 105, first movable plate 106, fixed bar 107, The first torsion spring 108, the first rotating plate 109, the limit rod 1010, the pressing plate 1011, the third spring 1012, the second fixed block 1013 and the second movable plate 1014, the second support plate 73 upper right side is provided with the sixth support plate 101, the front side of the sixth support plate 101 is provided with an inclined block 102, the upper right part of the rear side of the housing 1 is provided with a second fixed plate 103, and the upper right part of the second fixed plate 103 is provided with a guide rod 104, and the guide rod 104 is of sliding type A f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap