X-ray luggage safety inspection conveyor belt

A technology of safety inspection and conveyor belt, applied in the direction of using radiation for material analysis, etc., can solve the problems of low running speed of conveyor belt, low passenger walking speed, low efficiency and accuracy of luggage search, and time-consuming, so as to avoid corresponding difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

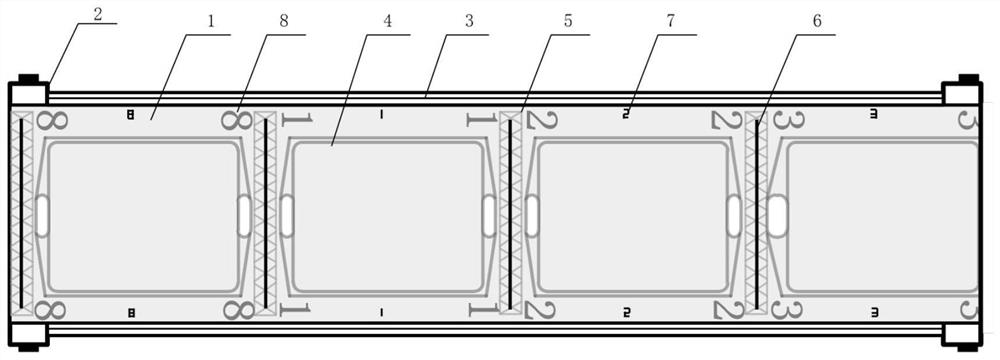

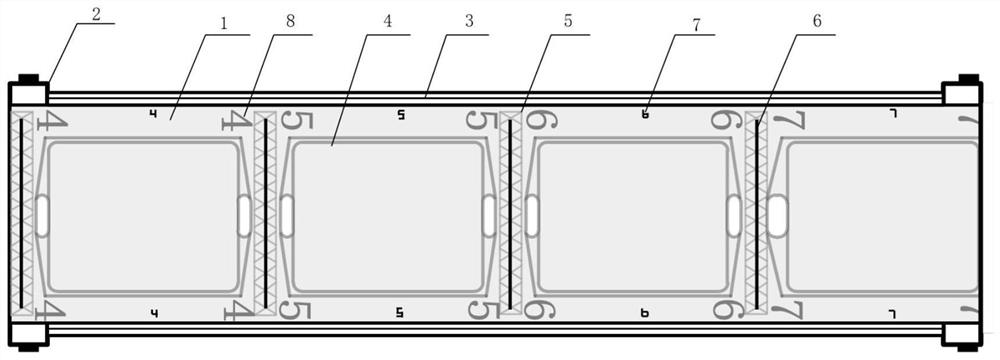

[0021] This embodiment provides a conveyor belt for X-ray baggage safety inspection, such as Figure 1-3 As shown, it includes a conveyor belt base 1, a roller member 2 positioned on both sides of the conveyor belt base 1, and a steel bracket support plate 3 for fixing the conveyor belt base 1; the conveyor belt base 1 is arranged at intervals along the conveying direction Tray pattern 4; each tray pattern 4 is provided with metal numbers 7 on both sides perpendicular to the conveying direction, and the four corners of each tray pattern 4 are provided with a number pattern 8, and each tray pattern 4 corresponds to a number pattern 8 It is the same number as the metal number 7; the number of the tray patterns 4 is an even number, and half of the tray patterns 4 are located on the half of the conveyor belt base 1 along the conveying direction, and the other half of the tray patterns 4 are located on the conveyor belt base 1 on the other half along the conveying direction, and th...

Embodiment 2

[0035] The structure of this embodiment and embodiment 1 is basically the same, the main difference is that, as Figure 4-6 As shown, in this embodiment, the interval between each tray pattern 4 is not provided with the identification pattern of the prohibited area for placing items and the metal or non-metal partition embedded in the conveyor belt belt base 1, but between each tray pattern 4 Set the bag isolation block 9, the bag isolation block 9 is made of rubber material, and is integrated with the conveyor belt base 1.

[0036] Further, the length of the bag spacer in the direction perpendicular to the conveying direction is less than or equal to the length of the belt base of the conveyor belt in the direction perpendicular to the conveying direction; the length of the bag spacer in the direction of conveyance should not be less than 10 mm, It should not be higher than 50mm, and the height of the bag partition should not be lower than 10mm and not higher than 100mm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com