Splicing structure to assist rapid hoisting of high-rise steel beams

A steel beam, fast technology, applied in building construction, building material processing, construction and other directions, can solve the problems of troublesome operation, high risk, complicated connection operation, etc., to achieve strong connection stability, easy to strengthen connection, realize Free and fixed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

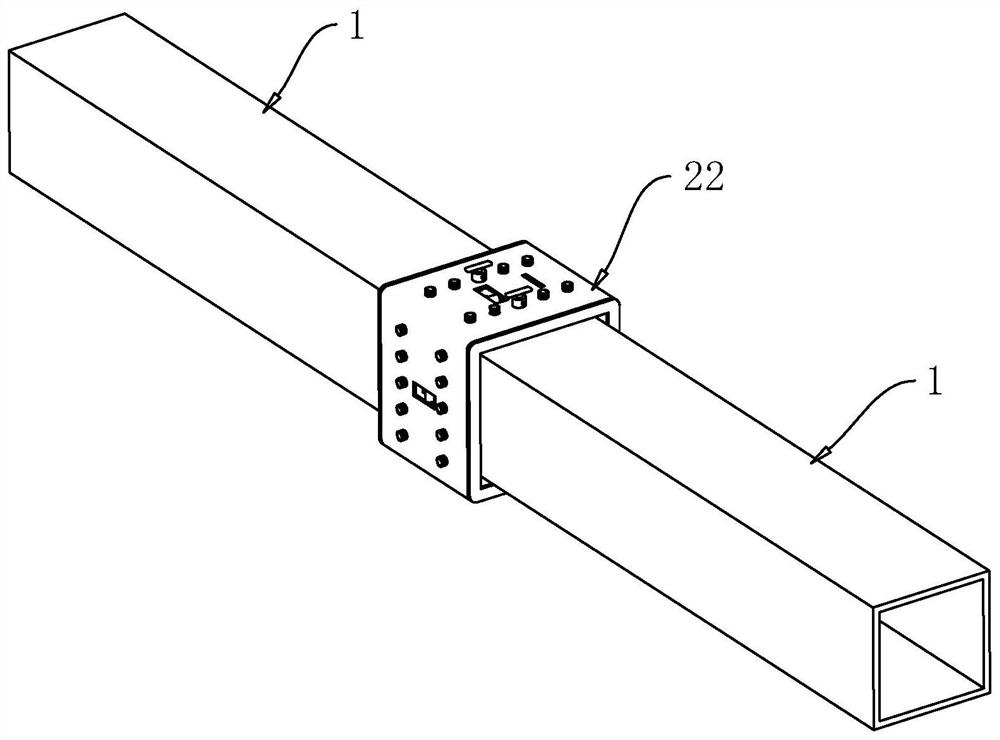

[0042] The embodiment of the present application discloses a splicing structure for assisting rapid hoisting of high-rise steel girders.

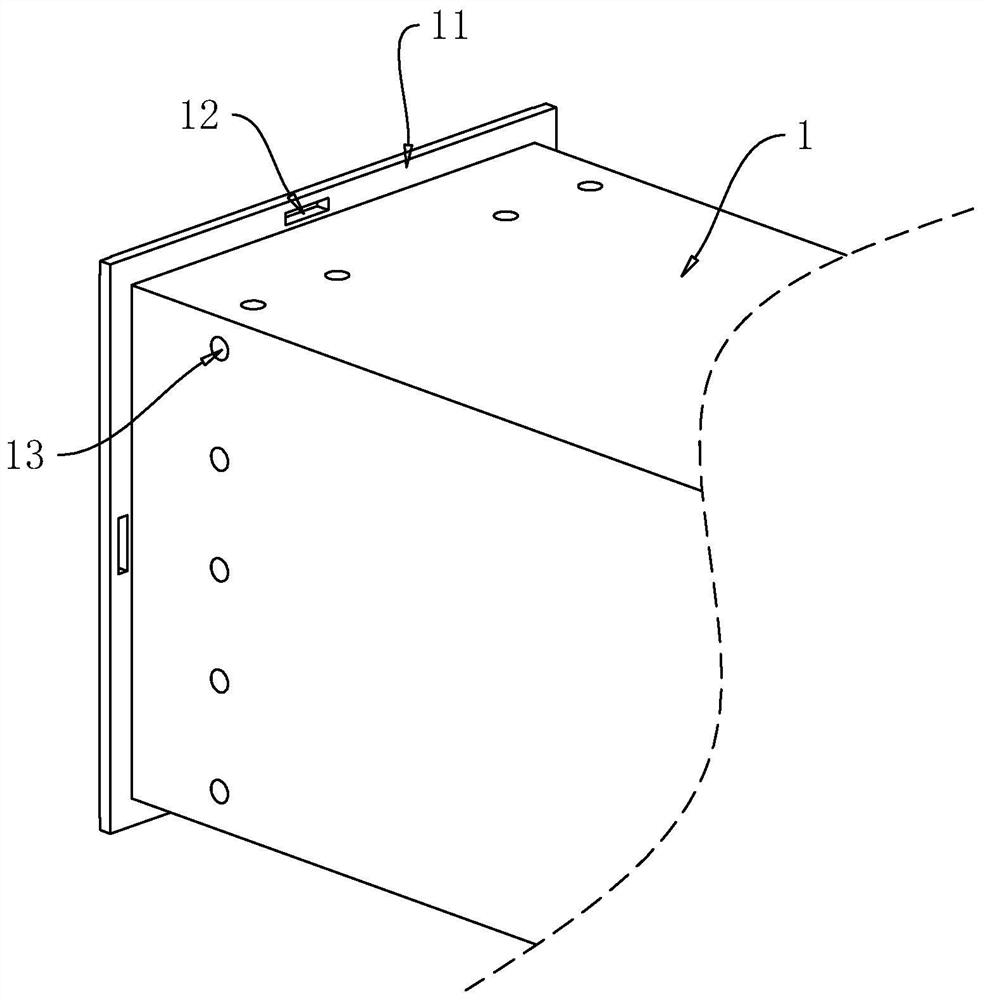

[0043] refer to figure 1 and figure 2 ,, a splicing structure for assisting the rapid hoisting of a high-rise steel girder 1, including a splicing plate 11 and a splicing frame 2 fixed at the end of the steel girder 1.

[0044] refer to figure 1 and figure 2 , the splicing plate 11 is fixed on the end face of the steel beam 1 , the shape of the splicing plate 11 is the same as the cross-sectional shape of the steel beam 1 , and the size of the splicing plate 11 is larger than that of the steel beam 1 . The splicing plate 11 and the steel beam 1 can be fixed by means of welding, bolt connection or the like.

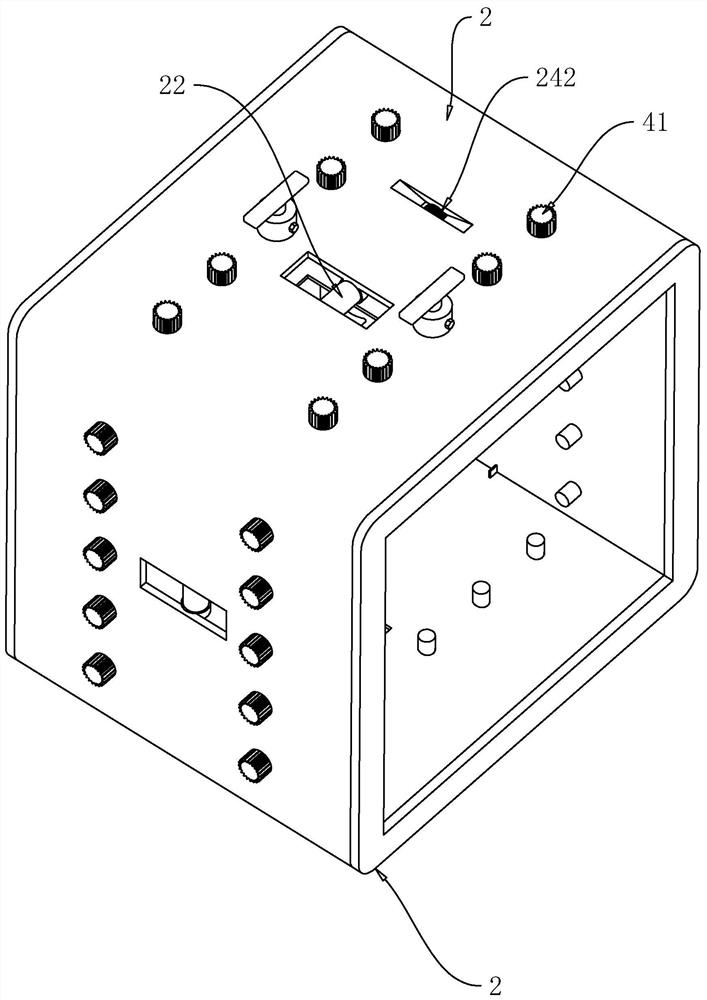

[0045] refer to image 3 , the splicing frame 2 is in the shape of a rectangular frame, and the size and shape of the inner hole of the splicing frame 2 are the same as the size and shape of the splicing plate 11, that is, after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com