Rotating chromatic range sensor system with calibration objects and method

一种对象、色度的技术,应用在色度范围传感器光学探针领域,能够解决执行、校准难以准确地执行、难测量地点等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

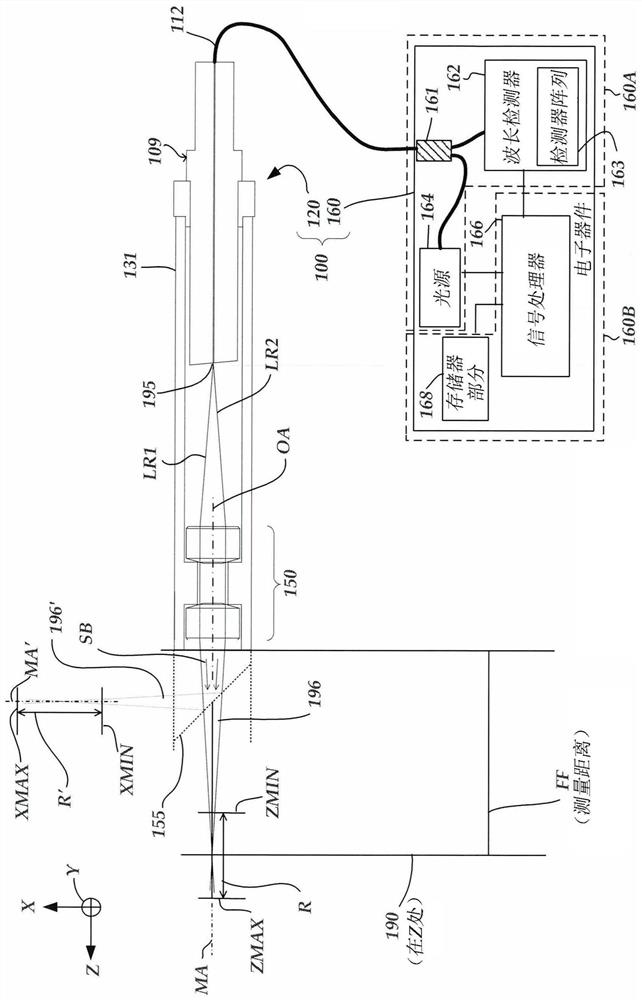

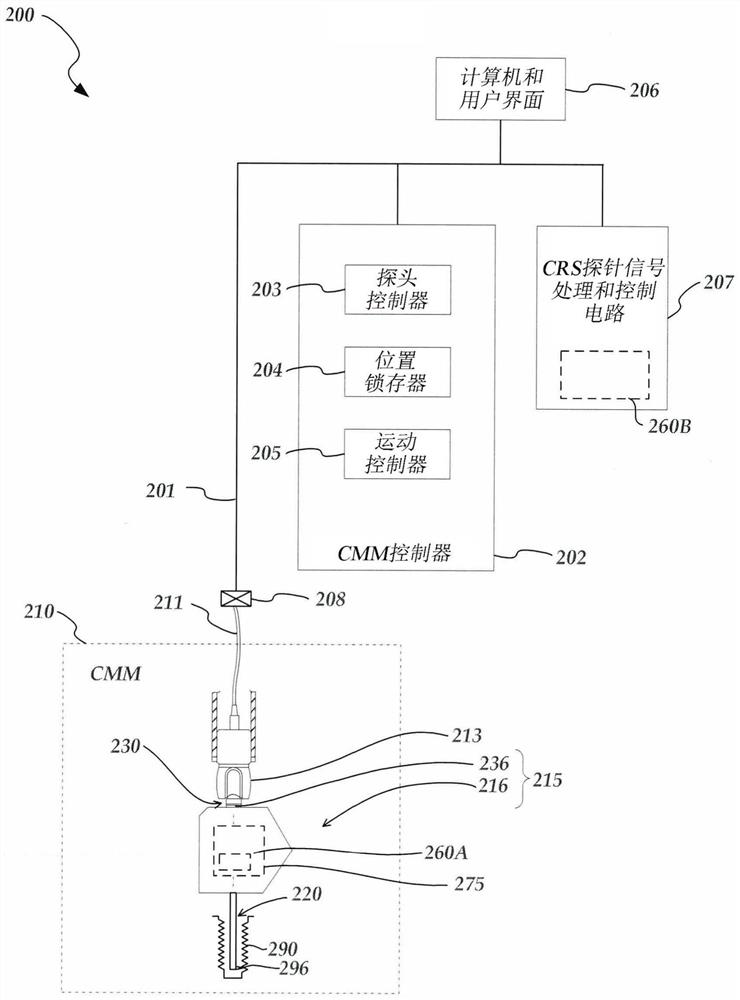

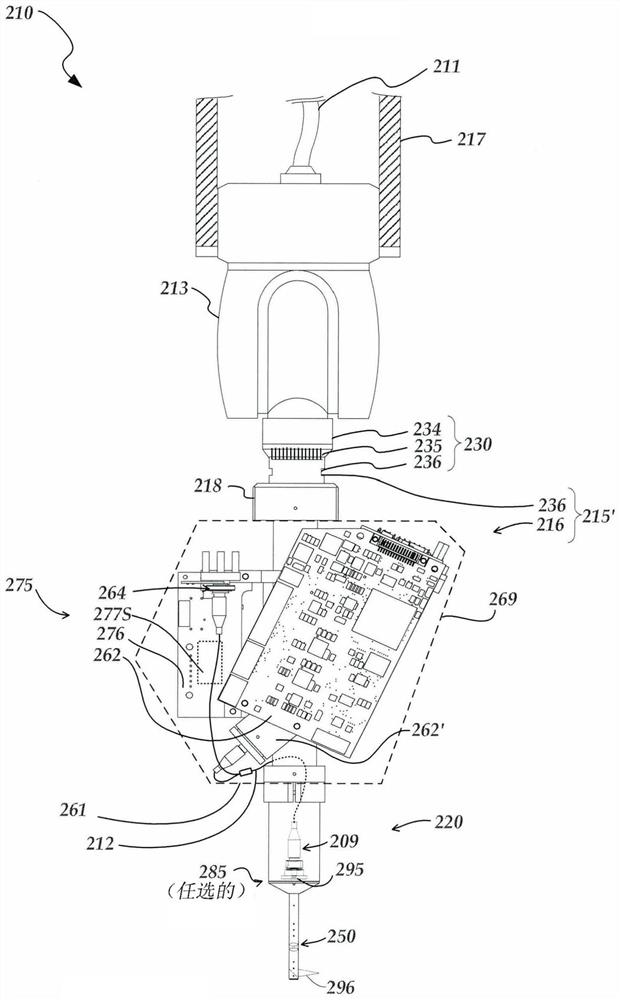

[0046] figure 1 is a block diagram of an exemplary colorimetric sensor (CRS) system 100 of a first type based on the principles of operation expected to be used in conjunction with a coordinate measuring machine. The CRS system 100 has certain similarities to the systems described in US Patent Nos. 7,876,456 and 7,990,522 (the '456 and '522 patents, respectively), which are hereby incorporated by reference in their entirety. As shown in FIG. 1 , CRS system 100 includes optics 120 and electronics 160 . It should be understood that figure 1 The illustrated CRS system 100 is a color point sensor system that, in some cases, can measure a single measurement point at a time. figure 1 The illustrated optical element 120 is an optical pen. However, in various embodiments, alternative types of chromaticity range systems may be utilized, such as chromaticity line sensors.

[0047] Optical pen 120 includes fiber optic connector 109 , housing 131 (eg, assembly tube) and optics portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com