Laminated stretched polyamide film

A polyamide film, polyamide technology, applied in the direction of layered products, synthetic resin layered products, packaged food, etc., can solve problems such as low cost, achieve economical, omit the coating process, and have good productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

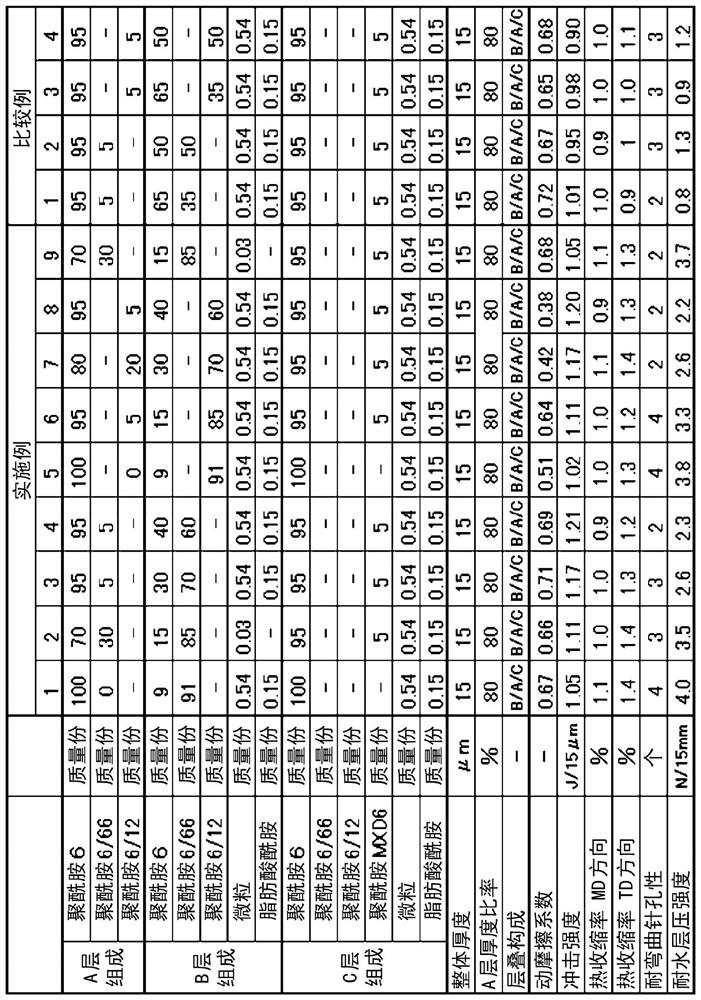

Embodiment 1

[0122] Using a device consisting of 1 caliber 60mm extruder for A layer and 2 caliber 25mm extruders for B and C layers and a 380mm wide co-extrusion T-die, the following materials are melt extruded: As the substrate layer (layer A), polyamide 6 (relative viscosity 2.8, melting point 220°C); as the easy-adhesive layer (layer B), polyamide 6 (relative viscosity 2.8, melting point 220°C) and polyamide 6 / 66 copolymer (the proportion of polyamide 66 is 7% by mass, the relative viscosity is 2.8, and the melting point is 198°C) is blended at a mass ratio of 9 / 91 and contains 0.54% by mass of silica fine particles, 0.15% by mass of ethylene A substance obtained by adding a base distearic acid amide; as an easy-slip layer (C layer), polyamide 6 (relative viscosity 2.8, melting point 220°C) contains 0.54% by mass of silica fine particles, 0.15% by mass % of ethylene bis stearic acid amide is added, and the feed block is laminated in the composition of easy-adhesive layer (B layer) / sub...

Embodiment 2

[0128] A laminated biaxially stretched polyamide film was produced in the same manner as in Example 1 except for the following, except that as the substrate layer (layer A), polyamide 6 and polyamide 6 / 66 copolymer were used as The mass ratio is 70 / 30 and melt-extruded. As the easy-bonding layer (layer B), polyamide 6 and polyamide 6 / 66 copolymer are blended in a mass ratio of 15 / 85, and will contain 0.03 The material obtained by adding silica particles (pore volume 0.8ml / g, average particle diameter 2.7μm) in mass % was melt-extruded, and as the slippery layer (layer C), polyamide 6 and MXD were mixed by weight The ratio is 95 / 5 compounded and melt extruded.

Embodiment 3

[0130]A laminated biaxially stretched polyamide film was produced in the same manner as in Example 1 except for the following, except that as the substrate layer (layer A), polyamide 6 and polyamide 6 / 66 copolymer were used as The ratio of mass ratio 95 / 5 is matched and melt-extruded, as the easy-bonding layer (B layer), polyamide 6 and polyamide 6 / 66 copolymer are melt-extruded with 30 / 70 mass ratio, as the easy-slip layer ( Layer C), polyamide 6 and MXD were blended and melt-extruded in a ratio of 95 / 5 by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com