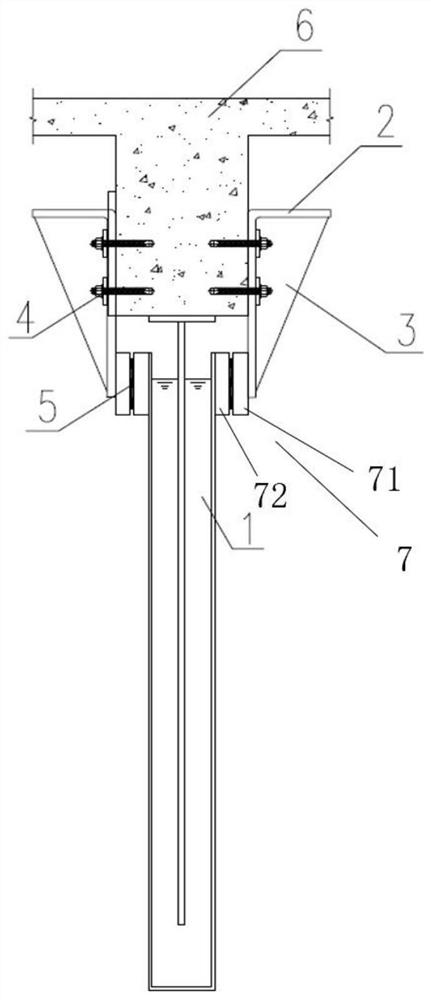

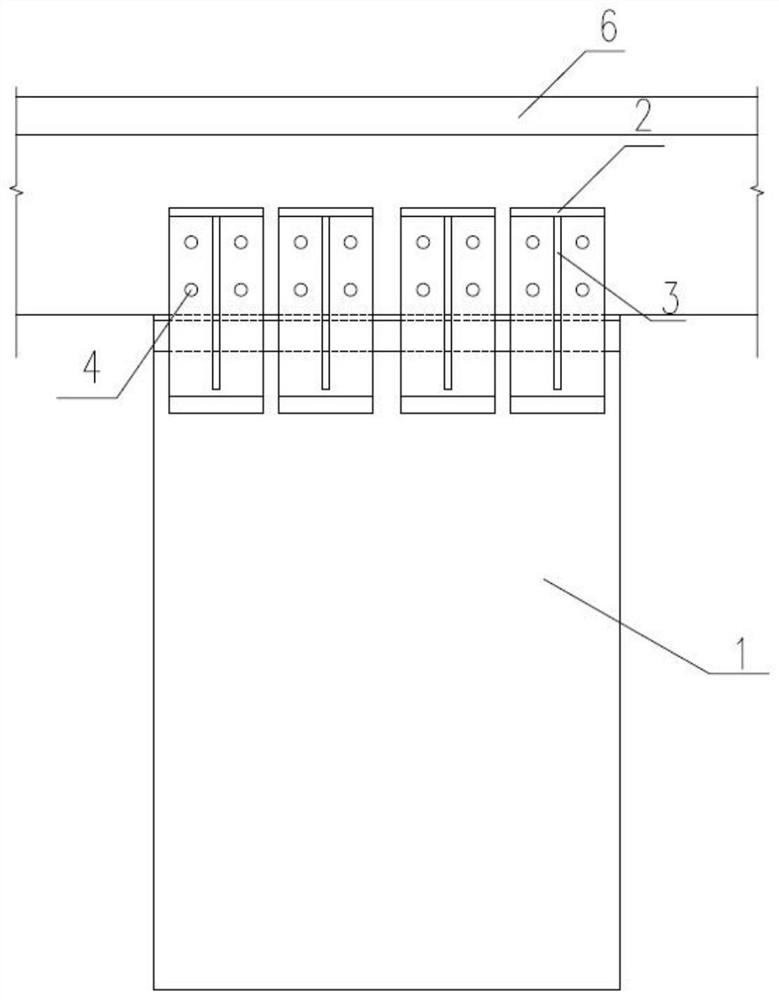

Structure and implementation method for solving out-of-plane rigidity of viscous damping wall

A technology of out-of-plane stiffness and viscous damping, which is applied in the direction of building construction, building components, and building materials, and can solve problems such as unreliable connections, inability to guarantee viscous damping energy consumption, and small clear distances between steel plates , to achieve the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions provided herein will be further described below in conjunction with specific embodiments and their drawings. By the following description, the advantages and features of the present application will be more clear.

[0019] It should be noted that the embodiments of the present application have preferred embodiments, not limited to any of the forms of the present application. The techniques or combinations of technical features or technical features described in the present application embodiments should not be considered isolated, they can be combined to achieve better technical effects. The scope of the preferred embodiments of the present application may also include additional implementation, and this should be understood by those skilled in the art of the present application.

[0020] For technical, methods, and equipment known to those of ordinary skill in the art may not be discussed in detail, in appropriate, the techniques, methods and equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com