Pipeline inner wall welding walking robot

A walking robot, pipeline technology, applied in the direction of pipes/pipe joints/pipes, special pipes, pipe components, etc., to achieve good practical effects, reduce risks, and reduce jitter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation.

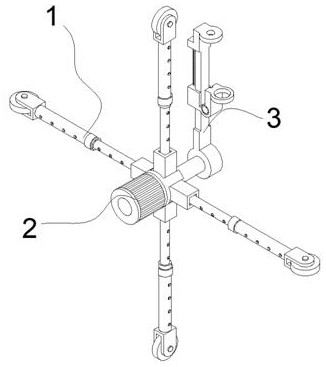

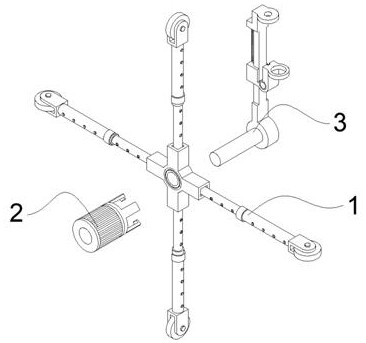

[0033] A walking robot for pipeline inner wall welding, comprising a walking frame structure 1, a welding adjustment structure 2, and a fixed welding head structure 3, the welding adjustment structure is fixed on the central front side of the walking frame structure 1, and the fixed welding head structure 3 It is arranged on the rear side of the walking frame structure 1, and the fixed welding head structure 3 passes through the center of the walking frame structure 1 and is connected with the welding adjustment structure 2.

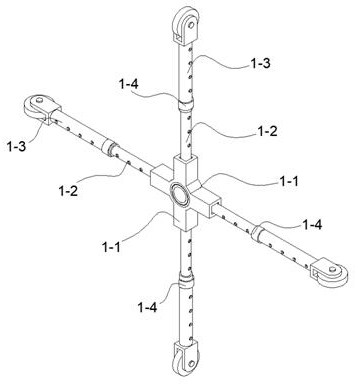

[0034] The walking frame structure 1 is composed of a structural center frame 1-1, a first-level energy-reducing connecting arm 1-2, a second-level walking adjustment connecting arm 1-3, and double-arm fixing buckles 1-4. There are four sets of connecting arms 1-2, secondary walking adjustment connecting arms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com