Full-automatic ring welding equipment

A fully automatic and equipment technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of labor-intensive, low welding accuracy, low welding efficiency, etc., to reduce welding costs, high welding accuracy, and high welding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

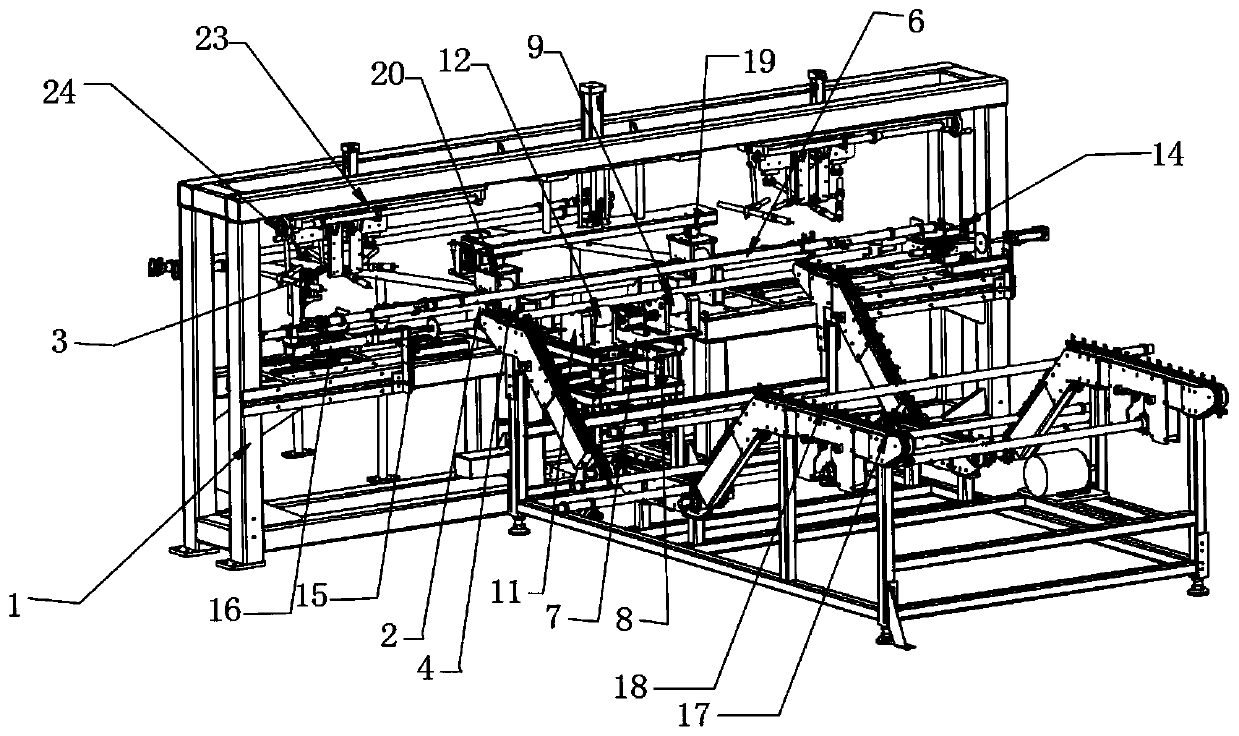

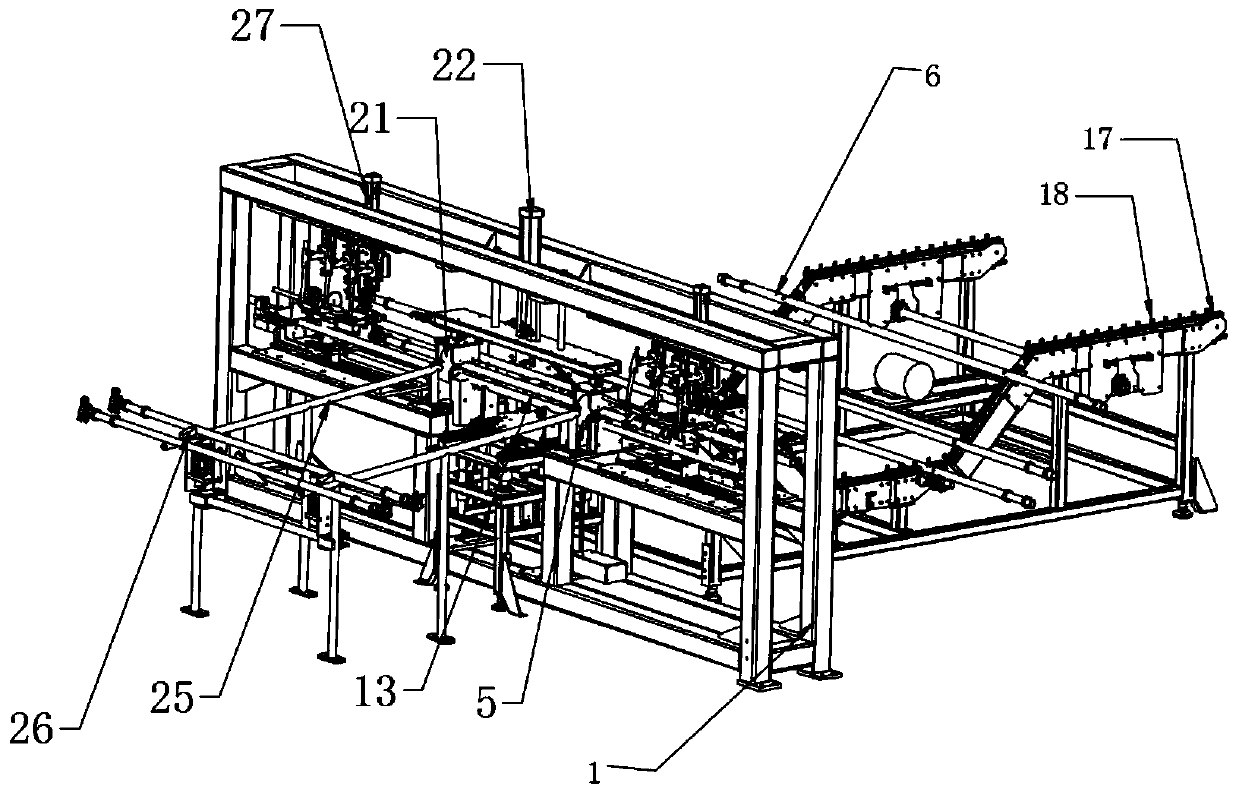

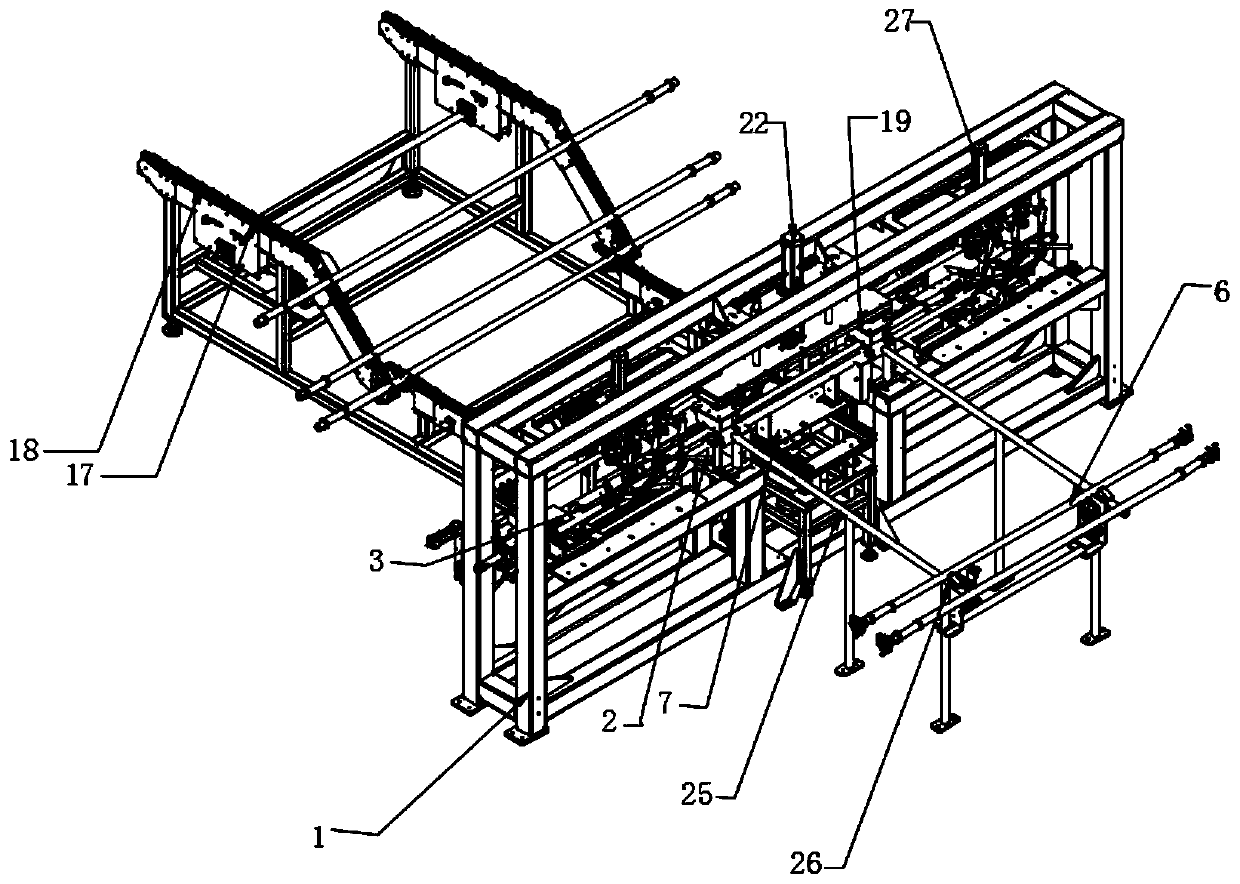

[0021] Embodiment: a fully automatic girth welding equipment, including a frame 1, girth welding station carrier 2, girth welding rotation drive device, wire feeding equipment, welding gun 3, welding gun feed drive device 27 and a control system, the ring welder The position carrier 2 is fixedly installed on the frame. The first runner 4 and the second runner 5 are rotatably installed on the girth welding station carrier 2. The first runner 4 and the second runner 5 are parallel in the horizontal direction. Arranged at intervals, the round pipe workpieces can be held between the outer circumferential surface of the first runner 4 and the second runner 5, and the girth-welded rotary drive device drives the first runner 4 and the second runner 5 to rotate in the same direction. The wire feeding equipment is fixedly installed on the frame. Several welding guns can be installed on the frame so as to move towards the circular tube workpiece on the girth welding station carrier. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com