Method for controlling a clutch unit

A clutch, friction clutch technology, applied in the direction of clutch, friction clutch, mechanical drive clutch, etc., can solve problems such as reducing the driving performance of motor vehicles, and achieve the effect of improving driving dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

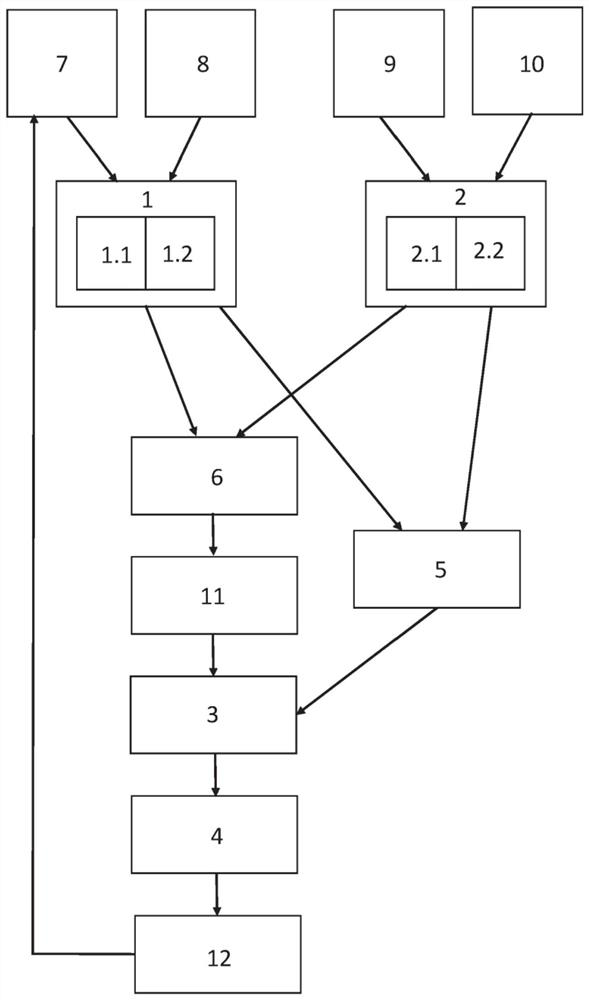

[0025] The sequence of the method according to the invention for controlling a clutch unit of a drive train of a motor vehicle is schematically shown in the figure.

[0026] The clutch unit controlled by the method includes an oil-cooled friction clutch for variably transmitting torque from an input member to an output member of the clutch unit. The output element of the clutch unit is connected in a rotationally fixed manner to the cardan shaft, so that the clutch unit transmits torque to the rear axle of the motor vehicle in a variably controllable manner.

[0027] According to the method, the heat input contributing to the oil heating of the clutch unit is first calculated in step 1 . The calculation includes determining the torque-dependent heat input as substep 1.1 of step 1, taking into account the heat input from the current torque of the drive train on the side of the output element 7 . Furthermore, the speed-dependent heat input 1.2 is taken into account in the calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com