A multi-axis grinding machine inner arc polygonal rod tower structure

A grinding machine and inner curved surface technology, which is applied in the field of sand mills, can solve the problems of insufficient grinding of materials and low grinding efficiency of sand mills, and achieve the effect of improving integrity and facilitating maintenance of tower rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below with reference to the accompanying drawings.

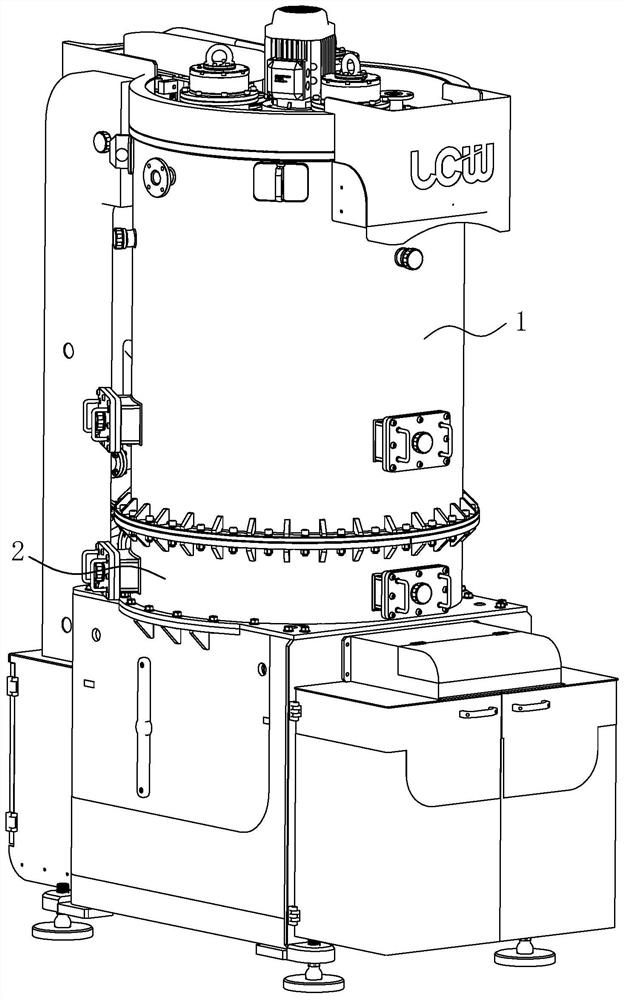

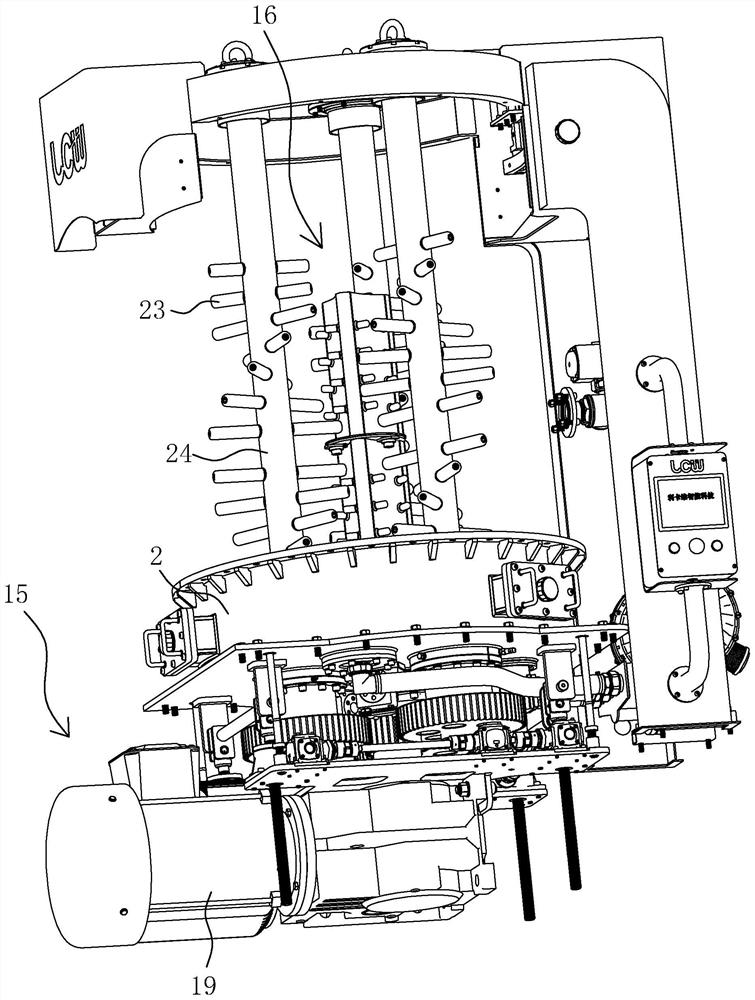

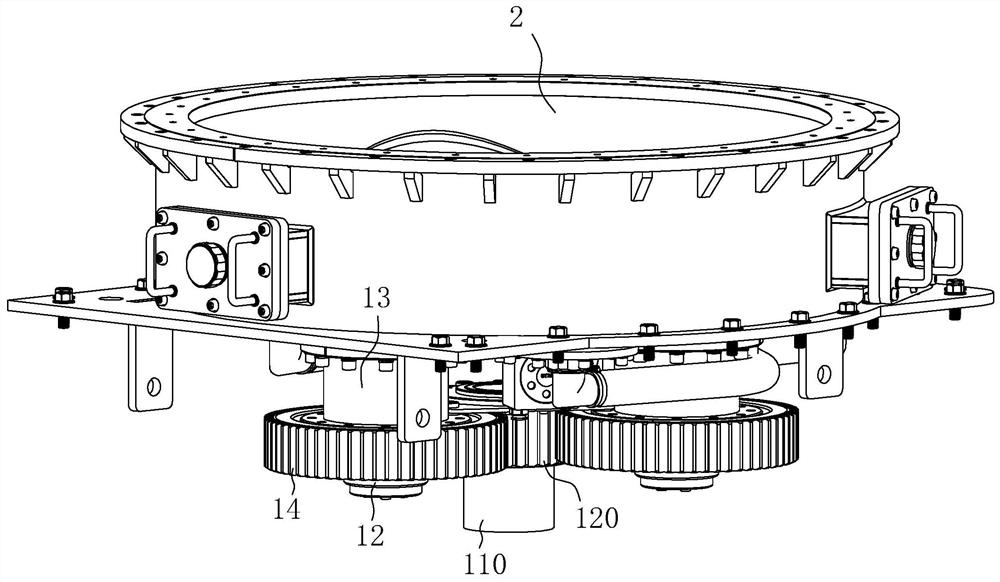

[0041] refer to figure 1 and figure 2, which is an inner arc polygonal rod tower structure of a multi-axis grinding machine disclosed in the present invention, comprising a base 2, a barrel 1 seated on the base 2, the barrel 1 is arranged in a cylindrical hollow, and the barrel 1 is integrally arranged in two Layer, three stirring rods 11 are arranged on the base 2, and the plane connecting lines of the three stirring rods 11 are arranged in an equilateral triangle. In order to reduce the dead space between the three stirring rods 11, a tower rod 16 is vertically arranged between the three stirring rods 11. , the side of the base 2 away from the stirring rod 11 is provided with a driving device 15. The driving device 15 includes a motor 19 on the fixed base 2. The operator can indirectly control the rotation of the stirring rod 11 through the motor 19. The op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com