Screw compressor bearing dismounting device and dismounting method

The technology of a bearing dismounting device and a screw compressor, which is applied in the field of compressors, can solve the problems of damage, high cost, complex and bulky structure, etc., and achieve the effects of enhancing physical and mental health, reducing labor intensity and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

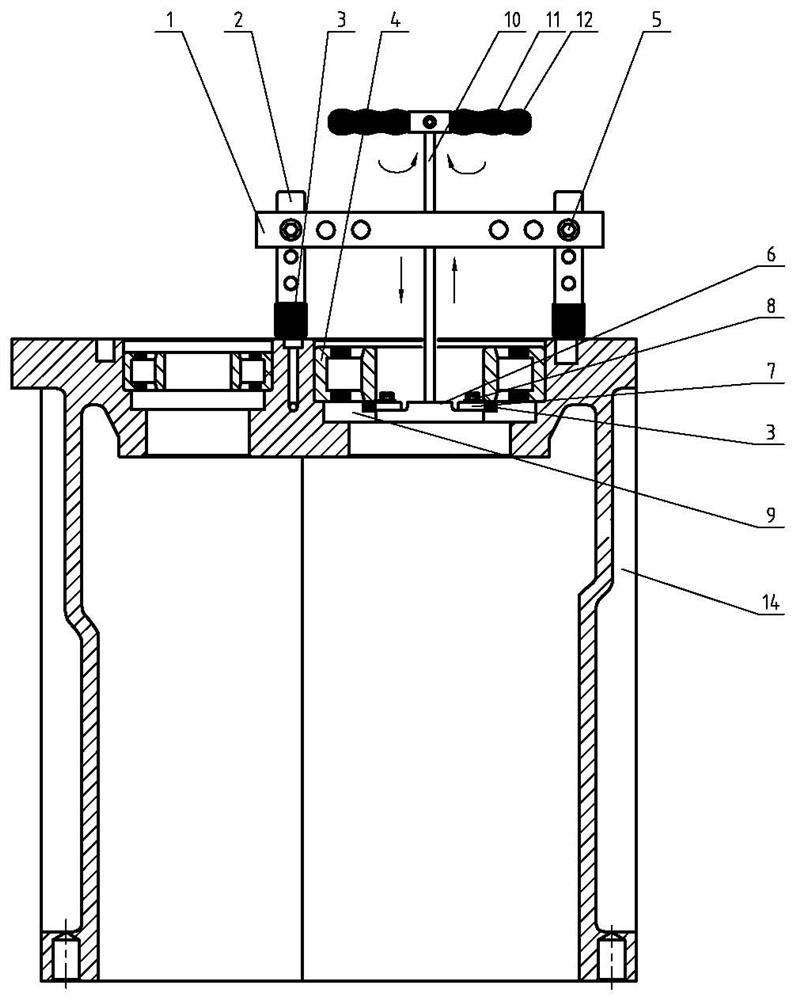

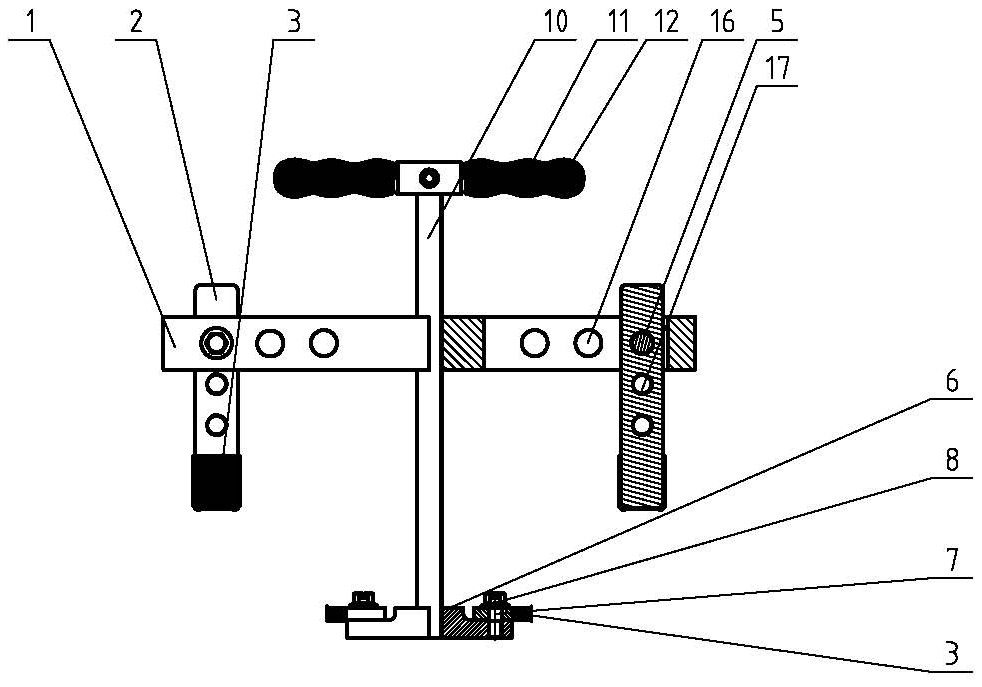

[0022] See figure 1 , figure 2 , image 3 As shown, a screw compressor bearing removal device includes a pressure plate 1, a threaded hole 13 is opened in the middle of the pressure plate 1 and a tie rod stud 10 is installed. An ergonomic grip 11 is installed on one end of the tie rod stud 10, and There is a disc 6, and the ergonomic grip 11 is provided with a PVC plastic sleeve 12, which has the effect of anti-slip and shock absorption, and at the same time improves the corrosion resistance and comfort of the grip. The disc 6 is provided with two ends The movable plectrum 7 that can extend out from the edge of the disc is specifically installed as one end of the movable plectrum 7 is installed on the disc 6 through a screw 8, the rotation of the screw 8 drives the movable plectrum 7 to rotate and the other end extends out of the disc 6, and the pressing plate 1. Support columns 2 are installed at both ends, and the ends of the support column 2 and the movable paddle 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com