Gear switching method of electronic gear shifter

An electronic shifter and gear switching technology, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problem of large size and weight, damage to the transmission structure, and can not meet the requirements of electrification and intelligence and other problems to achieve the effect of avoiding driving hazards and reducing the probability of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

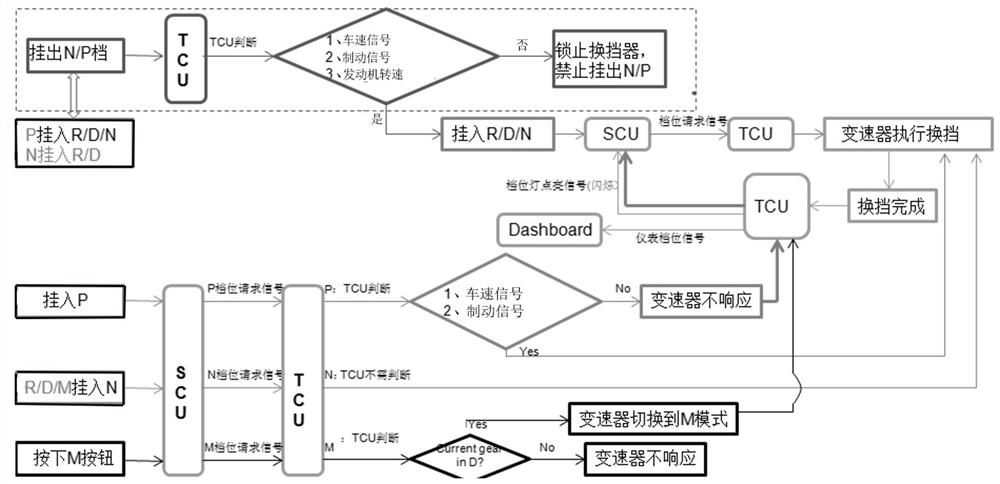

[0027] Refer to the attached figure 1 And embodiment the present invention is described in detail:

[0028] This set of shifting system is mainly composed of knob-type electronic shifter, electronic shifter control module SCU, transmission DCT, and transmission control module TCU, and the signals of each system are exchanged through the CAN bus.

[0029] The meaning of each gear is as follows:

[0030] P parking gear, or parking gear; N neutral gear; R reverse gear; D forward gear or driving gear;

[0031] A gear switching method of an electronic shifter of the present invention, the steps are as follows:

[0032] S1.P shift into R / D / / N gear or N shift into R / D gear:

[0033] S11. After receiving the driver's shift request, the SCU makes a judgment. The judgment conditions at this time are:

[0034] a. Whether the vehicle speed signal meets the preset requirements, such as the vehicle speed V is less than or equal to the calibration value V 0 ;

[0035] b. Whether the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com