Main cold roller mechanism of biaxially oriented film production line

A biaxially stretched film and production line technology, which is applied to flat products, household appliances, and other household appliances, can solve the problems of increased maintenance difficulty, limited structure that cannot realize auxiliary current limiting by wind force, and non-detachable roller body, etc. , to achieve the effect of improving installation efficiency and avoiding the reduction of auxiliary cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] as attached figure 1 To attach Figure 8 Shown:

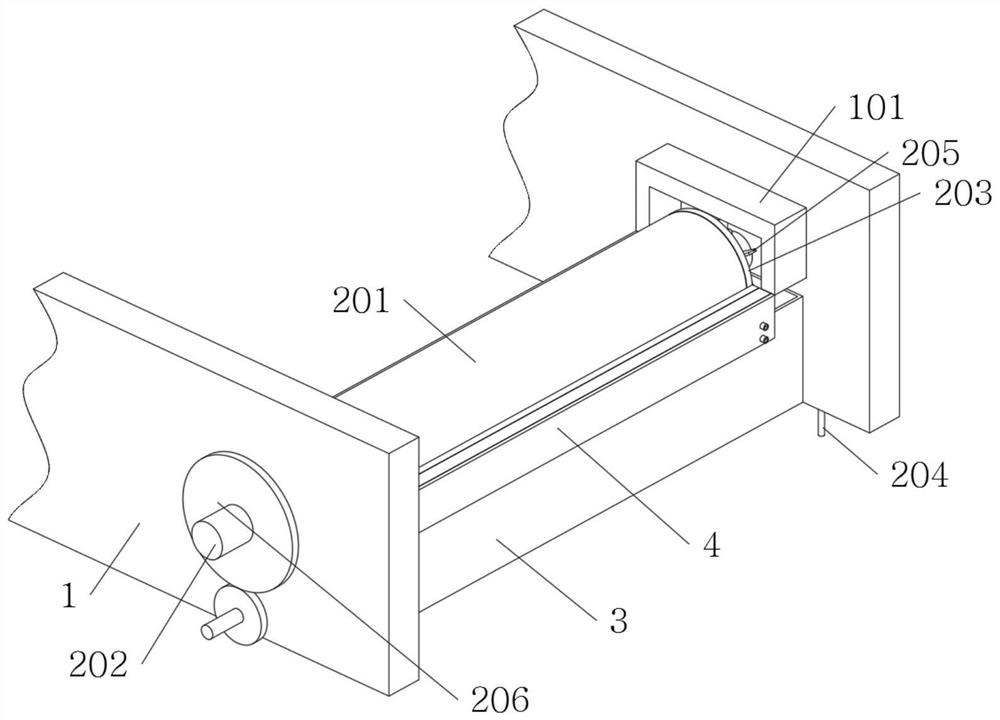

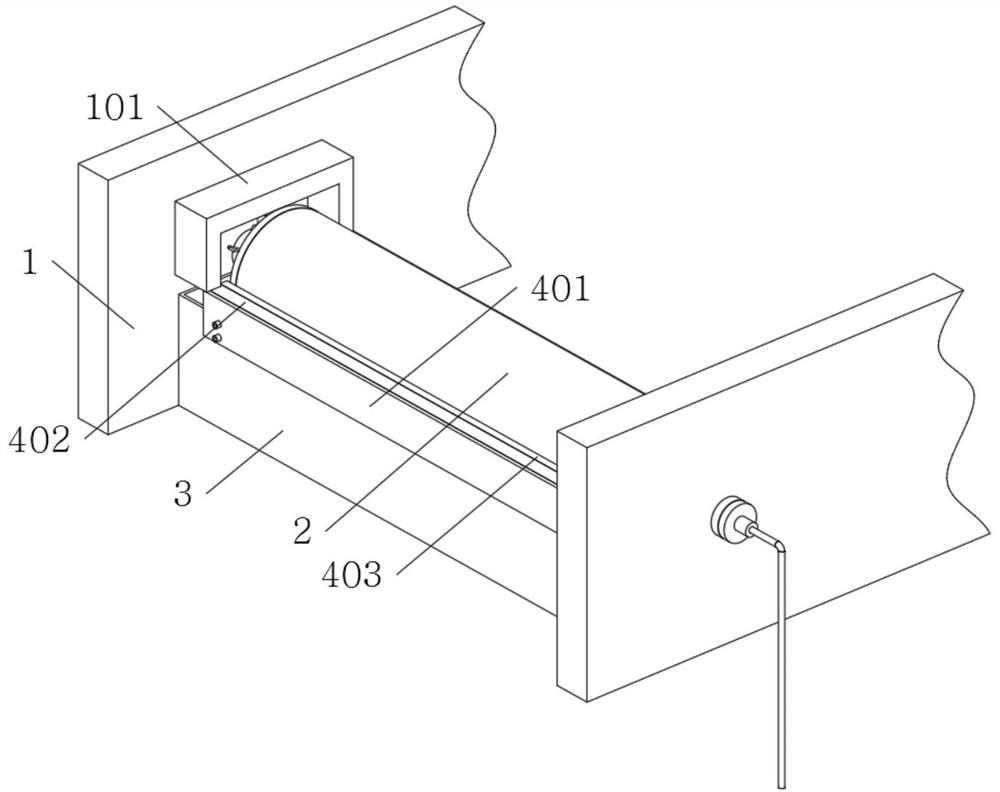

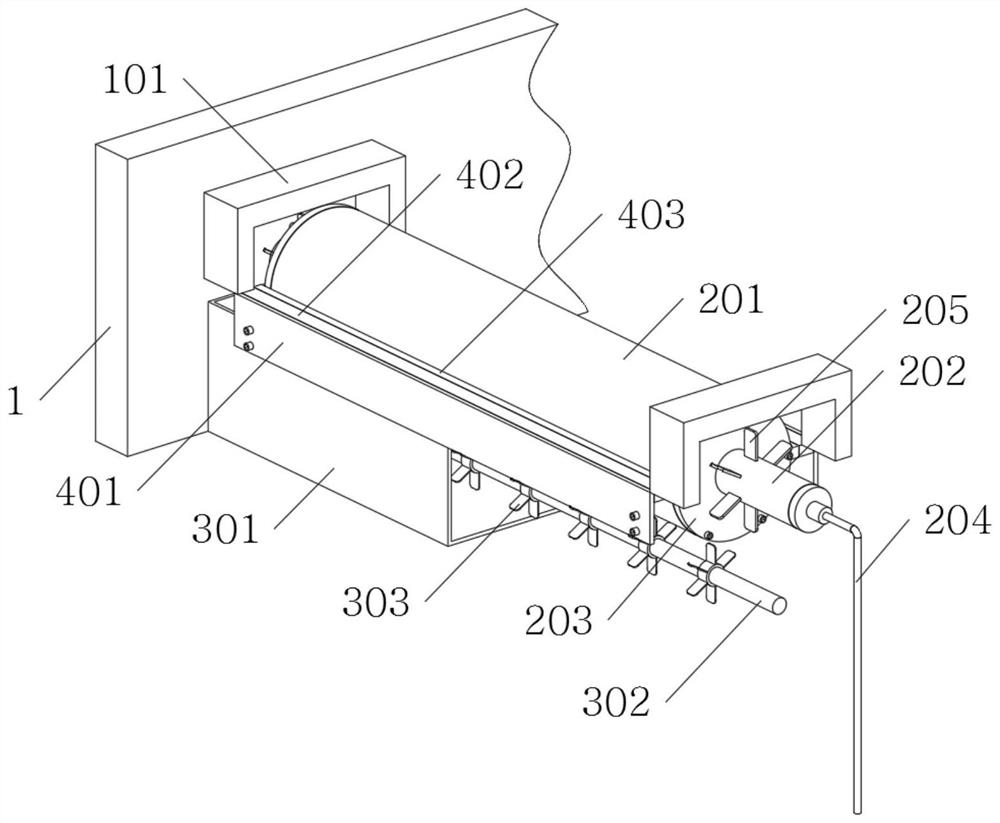

[0038] The present invention provides the main cooling roll mechanism of the biaxially stretched film production line, comprising a frame body 1; a cooling part 2 is installed on the frame body 1, and a second cooling part 3 is also installed on the frame body 1, and on the second cooling part 3 Two auxiliary parts 4 are installed; the second cooling part 3 includes: a box body 301, the box body 301 is a rectangular box-shaped structure, and the box body 301 is fixedly connected to the frame body 1 by bolts; the box body 301 is filled with cooling liquid , and the cooling liquid in the box 301 is in contact with the lower half of the outer wall of the roller body 201, so that the auxiliary cooling of the roller body 201 can be realized through the cooling liquid filled in the box body 301; the rotating shaft 302 is connected to the box body 301 in rotation , and blades B303 are installed in a linear array on the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com