Auxiliary weaving device for artificial silk flower manufacturing

An auxiliary device, a technology of silk flower making, is applied in the direction of braided fabrics, textiles, and papermaking. It can solve the problems of unfavorable wire winding operations, inconvenient mechanical drive connection, and inability to realize drive control, etc., and achieve the realization of installation connection and drive control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

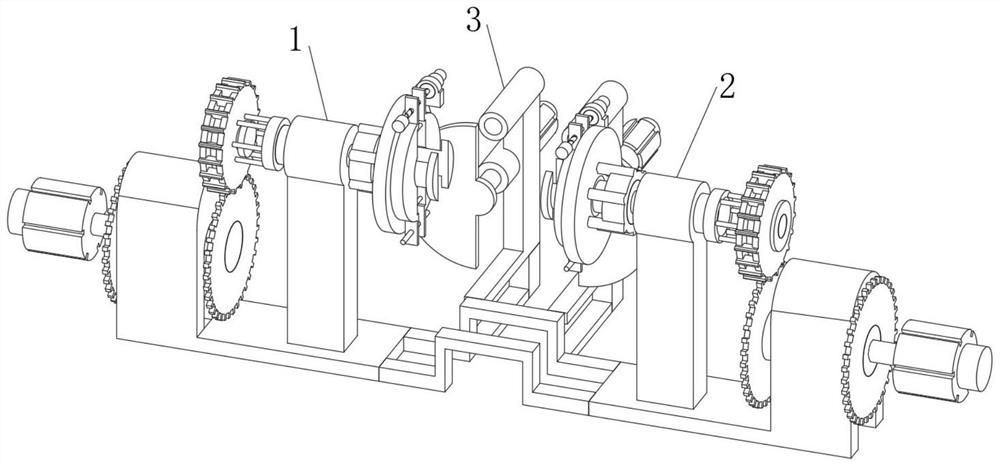

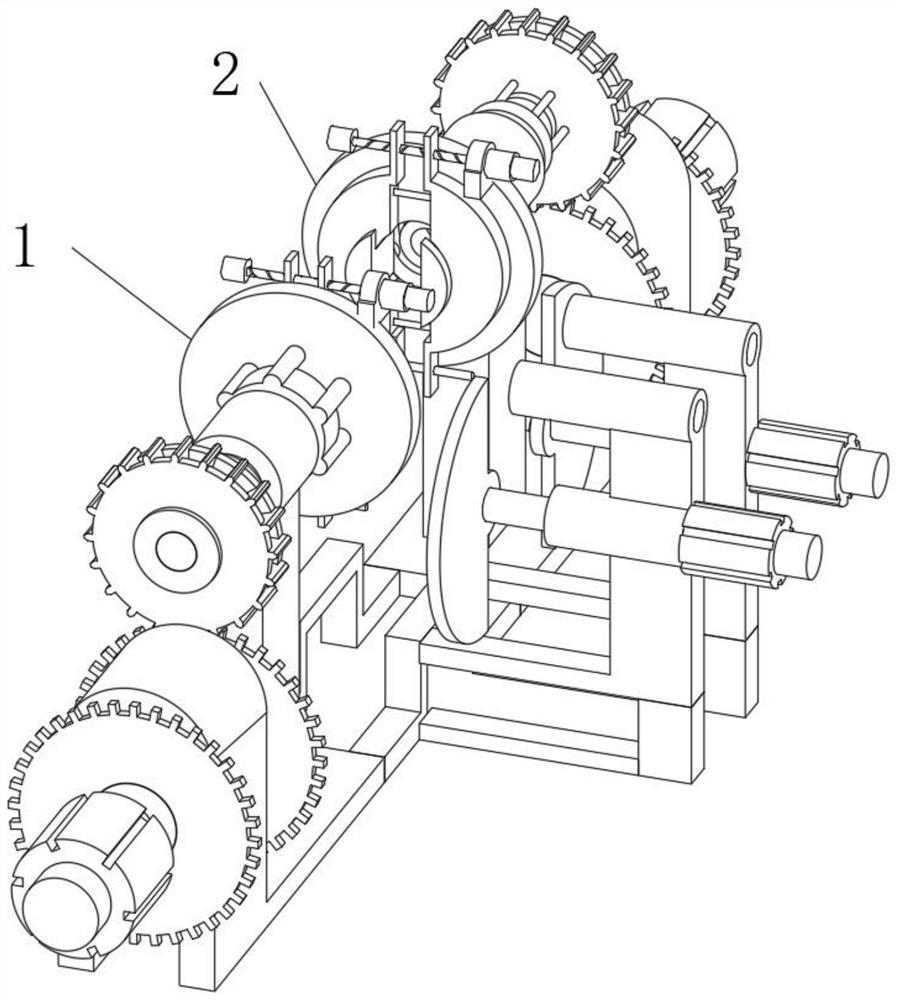

[0038] Such as Figure 1-3 As shown, a weaving auxiliary device for rayon flower making, it includes a first connection structure 1, a second connection structure 2 and a tailoring structure 3, the side end position of the first connection structure 1 is fixedly connected with a second connection Structure 2, the rear ends of the first connection structure 1 and the second connection structure 2 are symmetrically and fixedly connected with a tailoring structure 3;

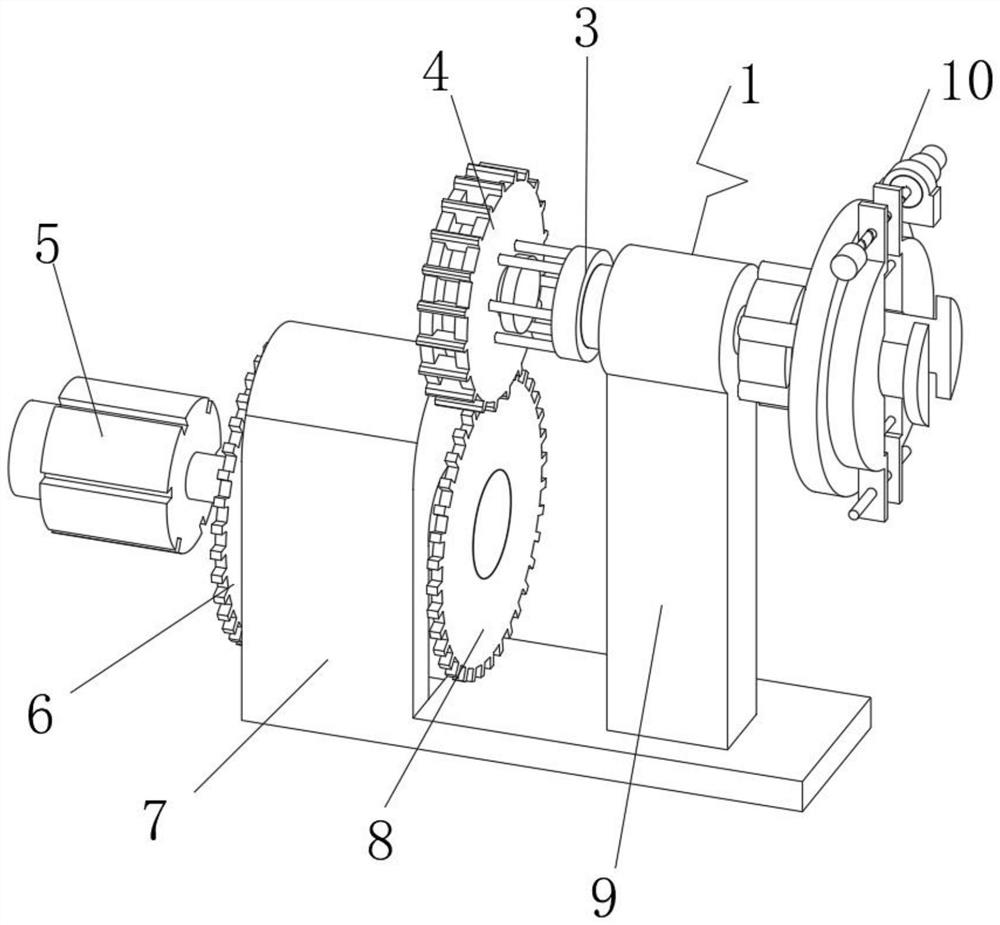

[0039]The first connection structure 1 includes a first toothed plate 4, a first motor 5, a second toothed plate 6, a connecting seat 7, a third toothed plate 8, a stand 9 and a winding component 10, the upper end of the connecting seat 7 A first motor 5 is installed on one side, the side end of the first motor 5 is fixedly connected to the third toothed plate 8 through the second toothed plate 6, and the other side of the upper end of the connecting base 7 is fixedly connected with a stand 9 The upper end of the ...

Embodiment 2

[0041] Such as Figure 1-4 As shown, as a further optimization scheme of the above-mentioned embodiment: a weaving auxiliary device for rayon flower making, it includes a first connection structure 1, a second connection structure 2 and a tailoring structure 3, the side of the first connection structure 1 A second connection structure 2 is fixedly connected to the end position, and a tailoring structure 3 is symmetrically fixedly connected to the rear end positions of the first connection structure 1 and the second connection structure 2;

[0042] The first connection structure 1 includes a first toothed plate 4, a first motor 5, a second toothed plate 6, a connecting seat 7, a third toothed plate 8, a stand 9 and a winding component 10, the upper end of the connecting seat 7 A first motor 5 is installed on one side, the side end of the first motor 5 is fixedly connected to the third toothed plate 8 through the second toothed plate 6, and the other side of the upper end of the...

Embodiment 3

[0044] Such as Figure 1-5 As shown, as a further optimization scheme of the above-mentioned embodiment: a weaving auxiliary device for rayon flower making, it includes a first connection structure 1, a second connection structure 2 and a tailoring structure 3, the side of the first connection structure 1 A second connection structure 2 is fixedly connected to the end position, and a tailoring structure 3 is symmetrically fixedly connected to the rear end positions of the first connection structure 1 and the second connection structure 2;

[0045] The first connection structure 1 includes a first toothed plate 4, a first motor 5, a second toothed plate 6, a connecting seat 7, a third toothed plate 8, a stand 9 and a winding component 10, the upper end of the connecting seat 7 A first motor 5 is installed on one side, the side end of the first motor 5 is fixedly connected to the third toothed plate 8 through the second toothed plate 6, and the other side of the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com