Splicing sealing structure of ventilating duct

A ventilation pipe and sealing structure technology, applied in the direction of pipe/pipe joint/pipe fitting, passing element, sleeve/socket connection, etc., can solve the problems of small sealing contact surface area, aging rubber sealing ring, poor sealing reliability, etc., to achieve The sealing contact area is large, the use stability is good, and the sealing reliability is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

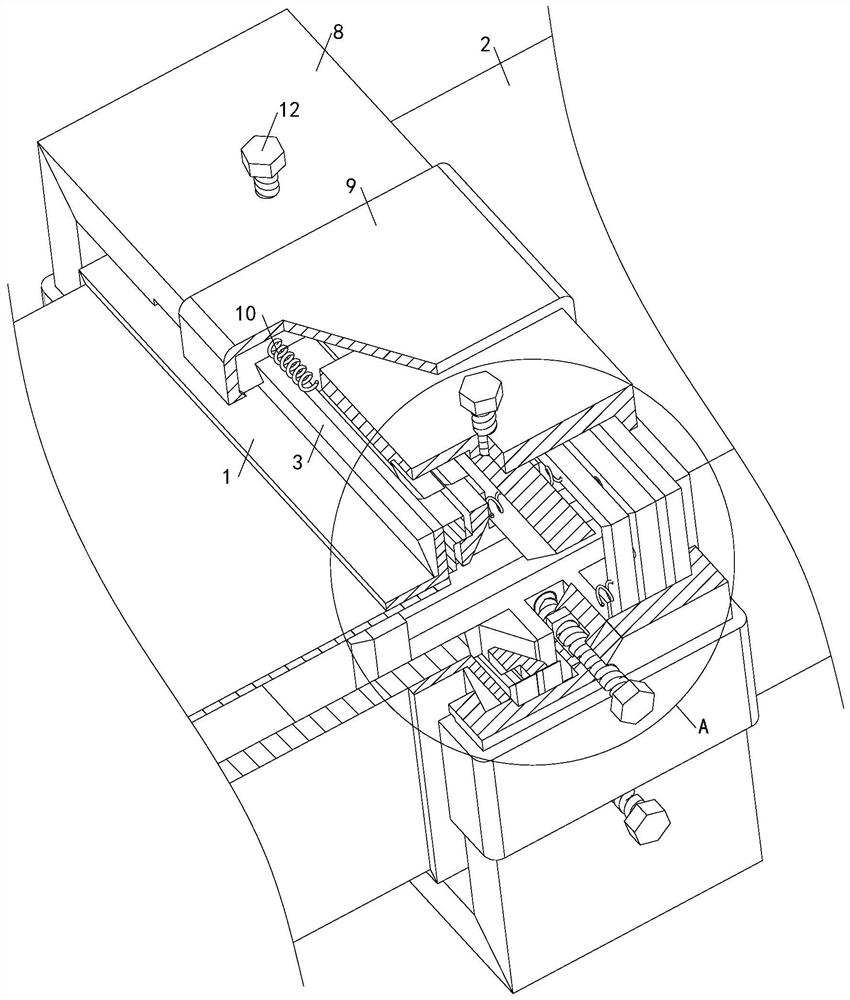

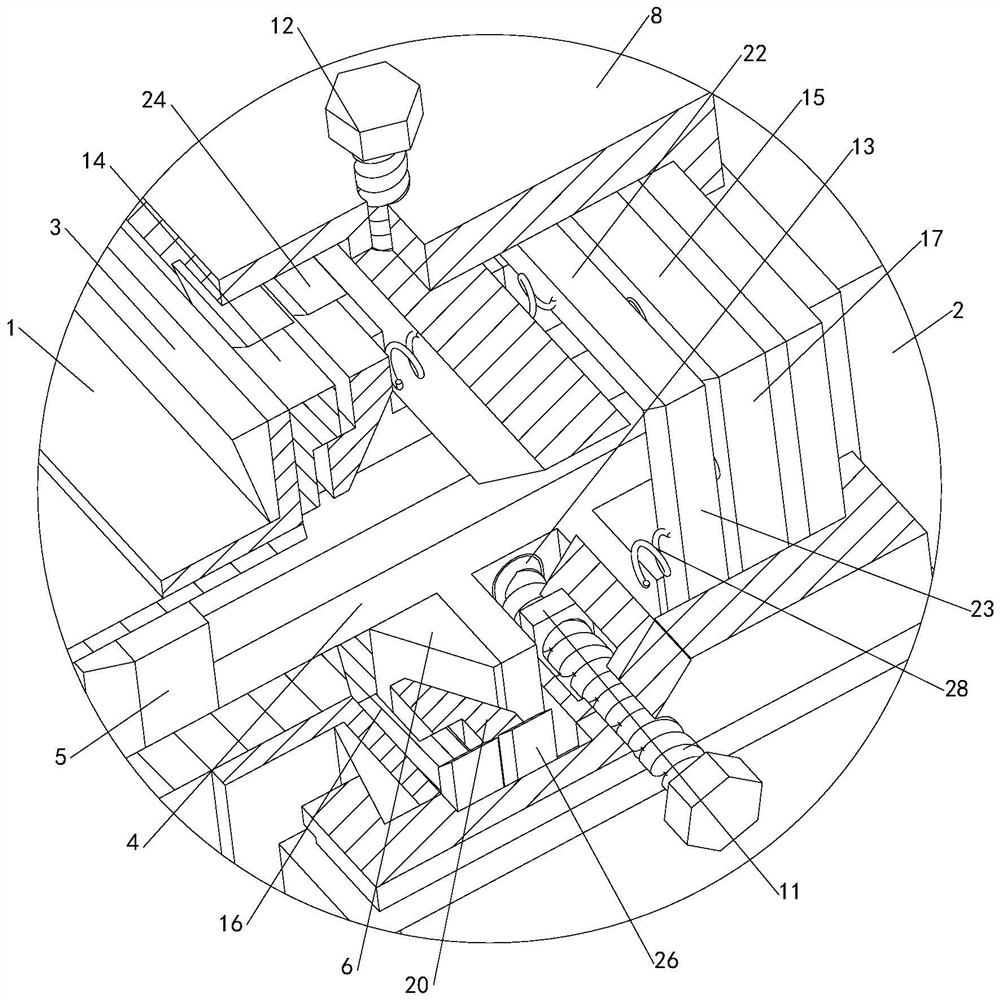

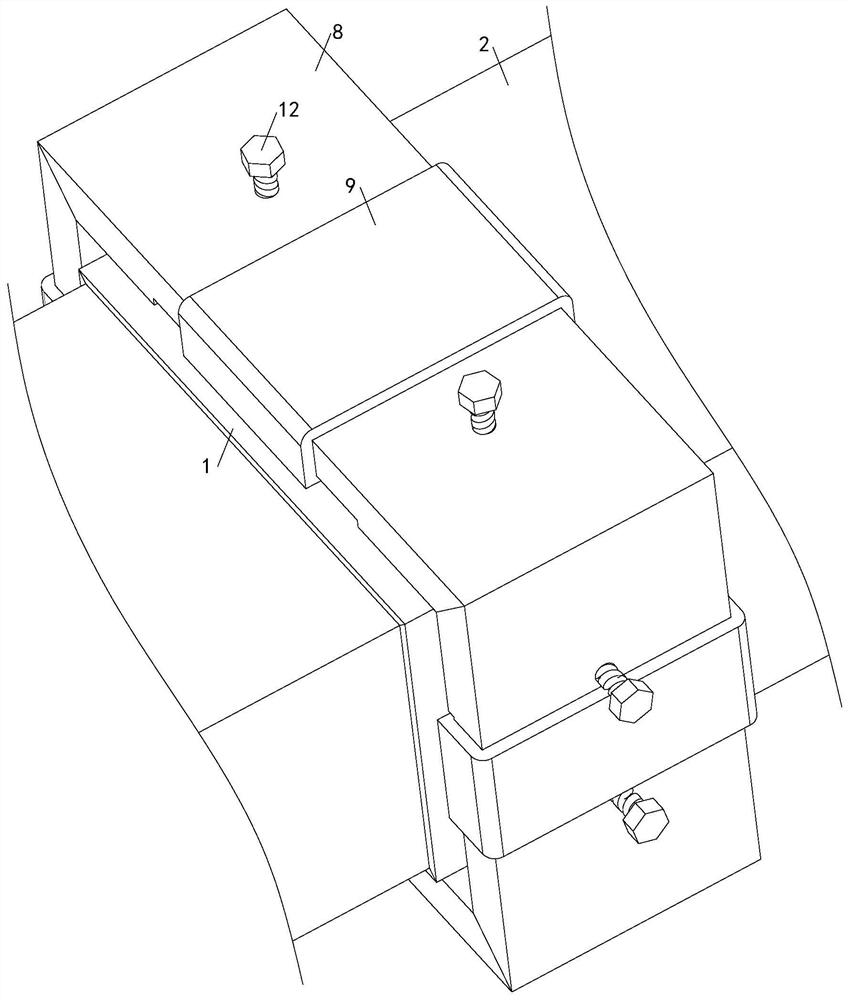

[0033] see Figure 1-7, a splicing and sealing structure for ventilation ducts, comprising two angle iron rings 1 and two ventilation ducts 2, the two angle iron rings 1 are respectively fixedly connected to the side walls of the two ventilation ducts 2, and also includes inner sealing components and The outer sealing assembly, the two angle iron rings 1 are fixedly connected with the gradient ring 3 matching the outer sealing assembly at the ends far away from each other, the inner sealing assembly includes four inner lining strips 4, and the inner lining strips 4 are close to the ventilation duct One end of 2 and the end of the inner corner sleeve 5 close to the ventilation duct 2 are all provided with a gasket, and the two adjacent inner lining racks 4 of the four inner lining racks 4 are connected through the corner sleeve 5, which can be realized internally. The sealing communication between the two ventilation ducts 2 has a larger sealing contact area and better sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com