Elastic pull-assisting pinned coupler

A pull-out type, connector technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the problem that the best labor-saving effect and fast plug-in and pull-out can not be achieved, and the service life of the plug connector Problems such as low and occupying the space of the converter, etc., achieve the effect of fast and labor-saving plugging and unplugging of the plug connector, saving space, avoiding offset and deformation movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

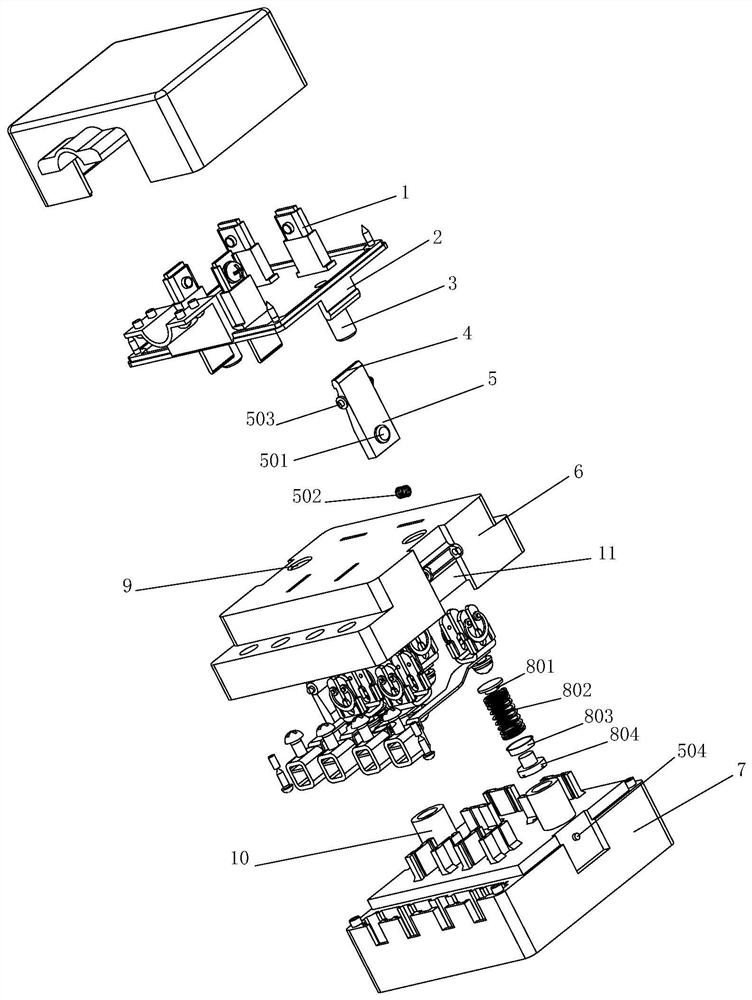

[0036] Embodiment one: if Figure 1-4 , including a latch assembly 1, a plug housing, a socket housing, an elastic component and a locking assembly. The plug assembly 1 is arranged at the lower end of the plug housing. The elastic component includes two elastic parts distributed inside the socket housing and two top blocks 3 arranged at the lower end of the plug housing, and the locking assembly includes two sets of locking parts and two matching trigger parts 5 . The top block 3 and the lock assembly are arranged on the same side, and the resistance is shared evenly, which is beneficial to reduce the resistance of the elastic parts to push out of the socket. The socket housing comprises a socket upper housing 6 and a socket lower housing 7. The socket upper housing 6 is provided with two holes A9 matched with the top block 3, the holes A9 are round holes, and the socket The lower casing 7 is provided with a groove B10 with a cylindrical opening directly below the hole A9, ...

Embodiment 2

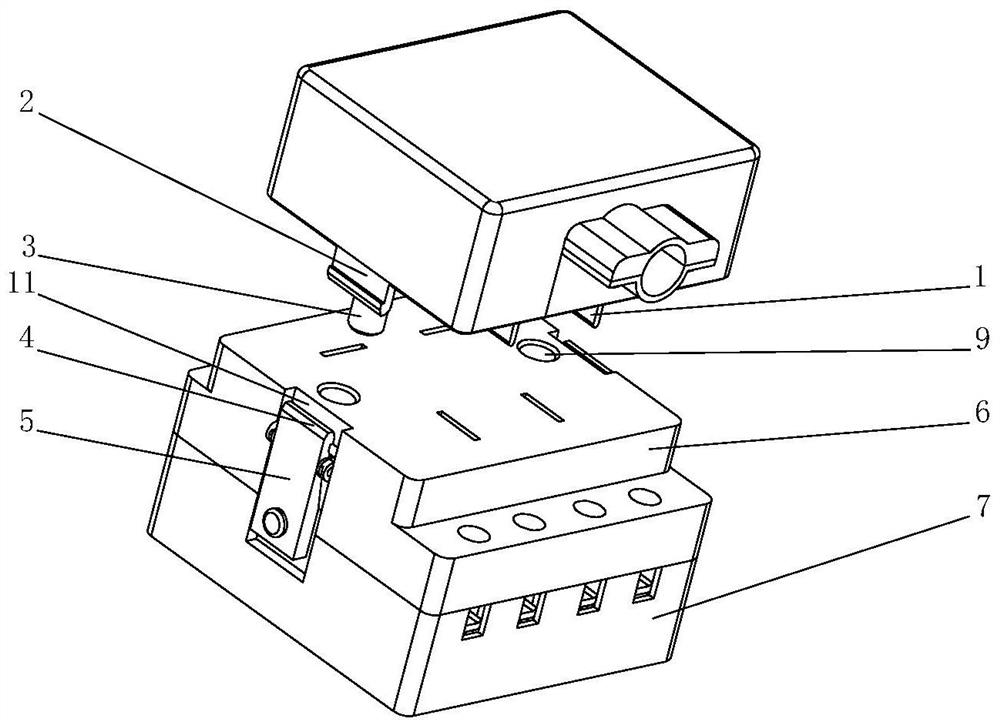

[0041] Embodiment 2: as Figure 5-7 , including a latch assembly 1, a plug housing, a socket housing, an elastic component and a locking assembly. The plug assembly 1 is arranged at the lower end of the plug housing, and the elastic component includes an elastic part located in the middle of the socket housing and a top block 3 arranged at the lower end of the plug housing. The lock assembly includes two sets of locking parts and two matching trigger parts 5 . The socket housing includes a socket upper housing 6 and a socket lower housing 7. The socket upper housing 6 is provided with a hole A9 matching the top block 3, and the hole A9 is a round hole. The socket lower housing 7 is provided with a cylindrical opening groove B10 directly below the hole A9. The side end of the socket upper housing 6 is provided with a rectangular groove C11 matching the trigger part 5, and the trigger part 5 is arranged at the groove C11, which can reduce the influence of the lock assembly on ...

Embodiment 3

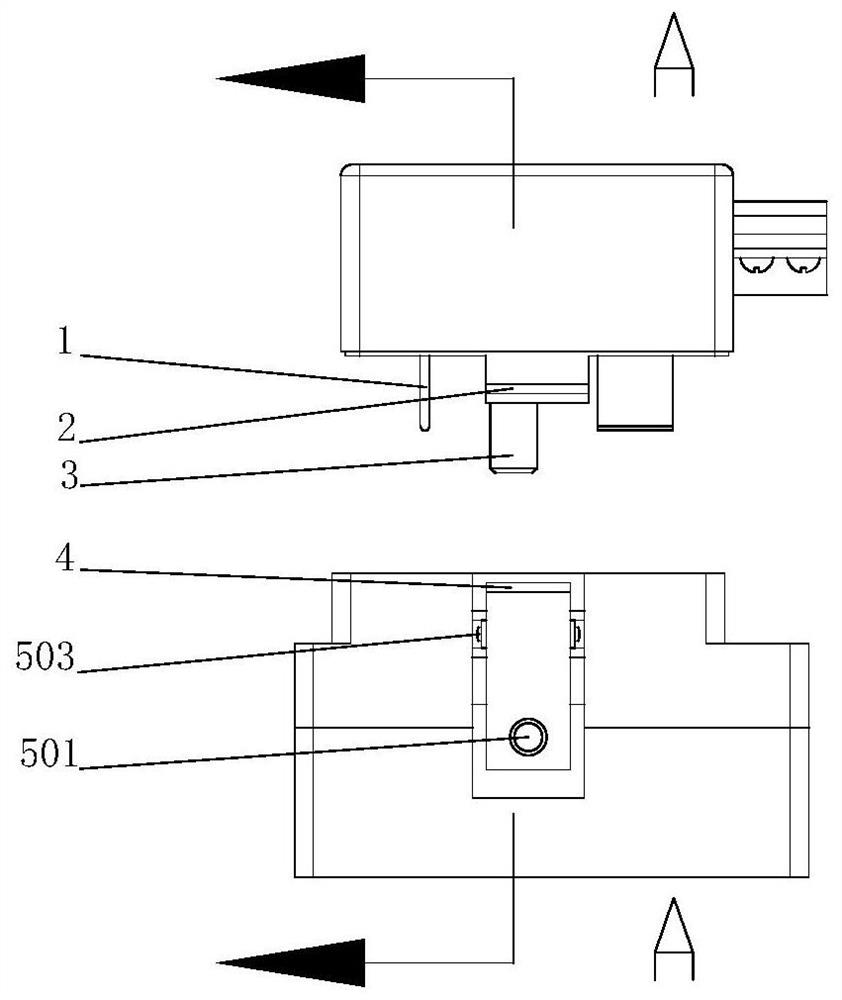

[0045] Embodiment 3: as Figure 8-10, including a latch assembly 1, a plug housing, a socket housing, an elastic component and a locking assembly. The plug assembly 1 is arranged at the lower end of the plug housing, and the elastic member includes two elastic parts located at both ends of the socket housing and two top blocks 3 arranged at both ends of the plug housing. The lock assembly includes two sets of locking parts and two matching trigger parts 5 .

[0046] The socket housing includes a socket upper housing 6 and a socket lower housing 7 . The upper end of the top block 3 is fixedly connected to the lower surface of the plug housing. The middle of the top block 3 is a cube and the lower end is a cylinder. The width of the cube is larger than the diameter of the cylinder, so there is a step between the middle and the lower end of the top block 3 Surface A. The socket upper shell 6 has a square through hole A9 matching the cube of the top block 3, and the socket lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com