Efficient paint spraying equipment for wooden door processing and surface paint spraying technology

A technology for spraying equipment and wooden doors, which is applied in the direction of spraying devices, liquid spraying devices, etc., and can solve the problems of lack of automatic painting and automatic feeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

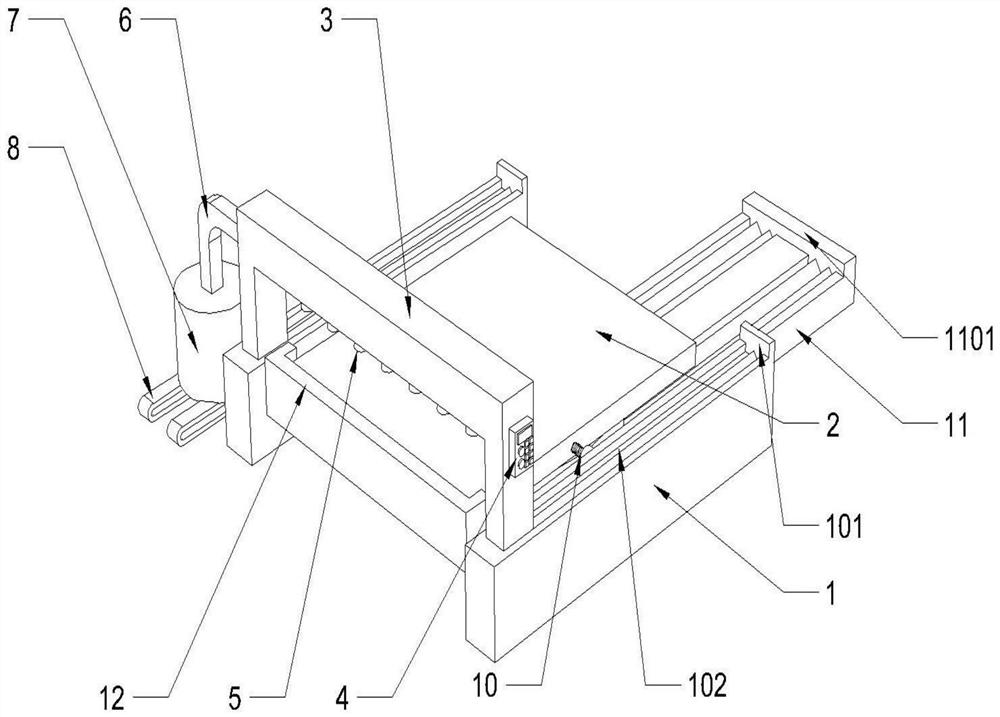

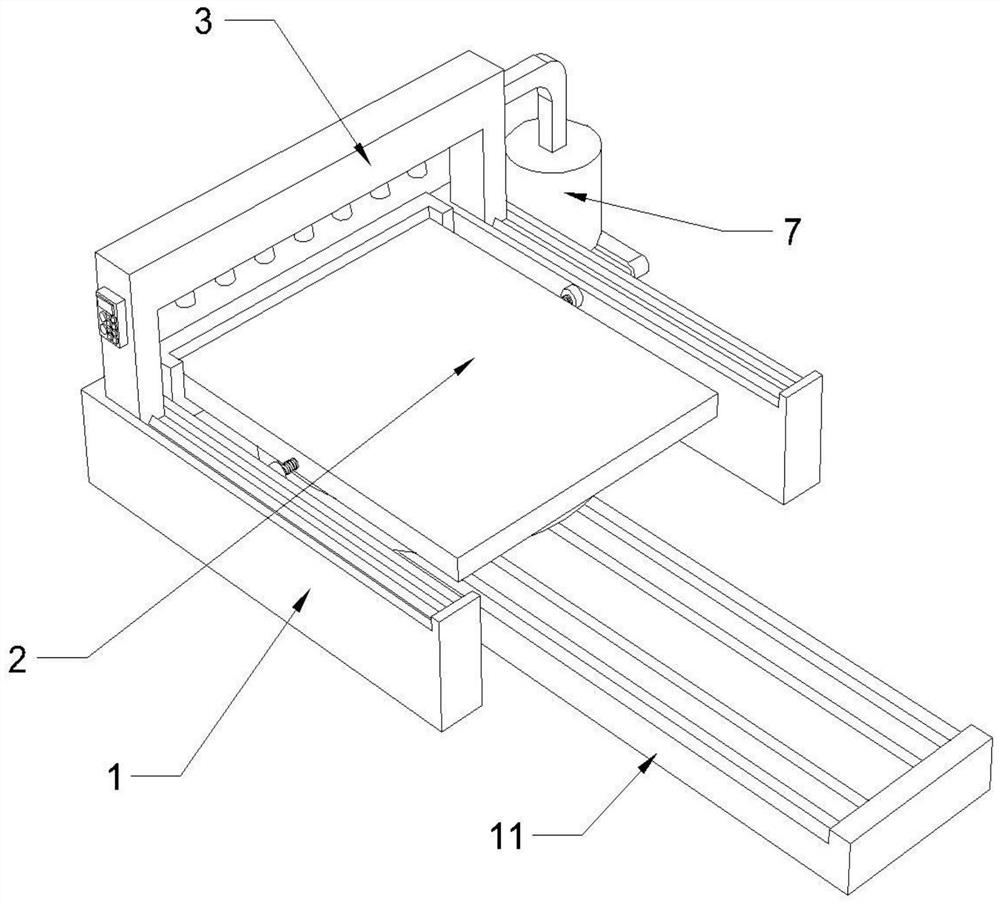

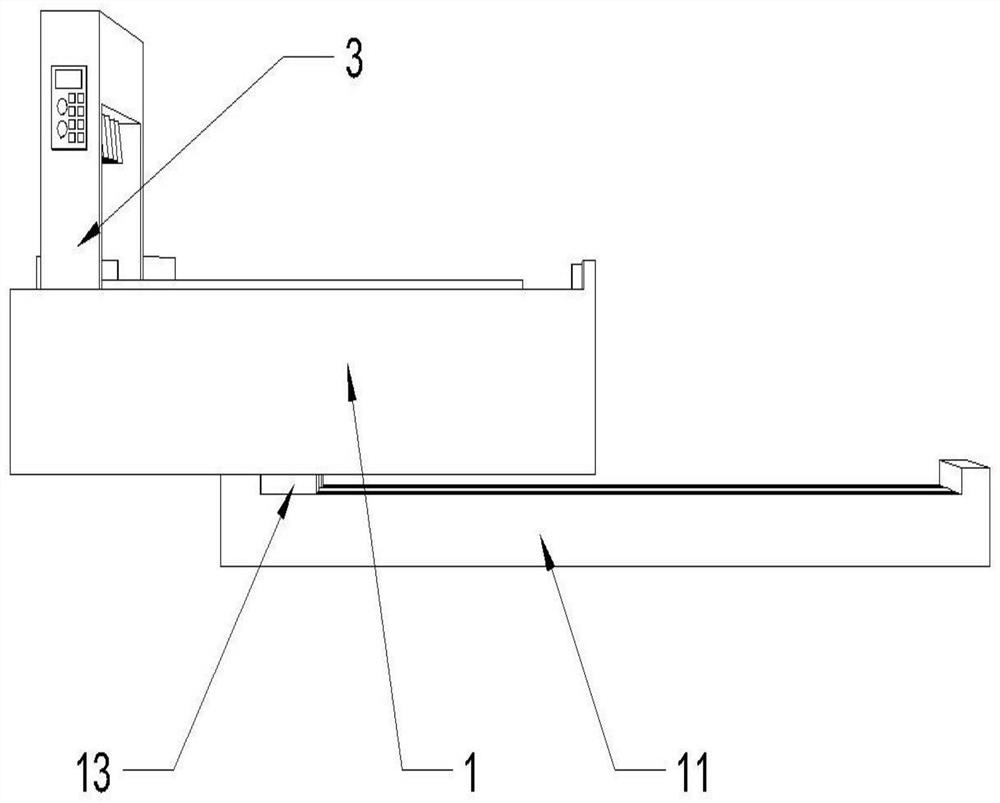

[0025] see Figure 1 to Figure 6 , a kind of high-efficiency painting equipment and surface painting process for wooden door processing, a guide rail seat 1, a guide rail baffle 101 is arranged on the upper end of the guide rail seat 1, a guide rail 102 is arranged in the middle of the guide rail baffle 101, and a paint spraying rack 3 is connected above the two guide rails 102, One side of the paint spraying frame 3 is provided with an operation panel 4, and the top of the operation panel 4 front side is provided with a liquid crystal screen 401, and the left side of the liquid crystal screen 401 bottom is provided with a power switch 402, and the right side of the power switch 402 is provided with a setting button 403, and the paint spraying frame 3 is provided with a setting button 403 in addition. One side is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com