Special-shaped steel pipe machining device for municipal building materials

A special-shaped steel pipe and processing device technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low degree of automation, inconvenient operation, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

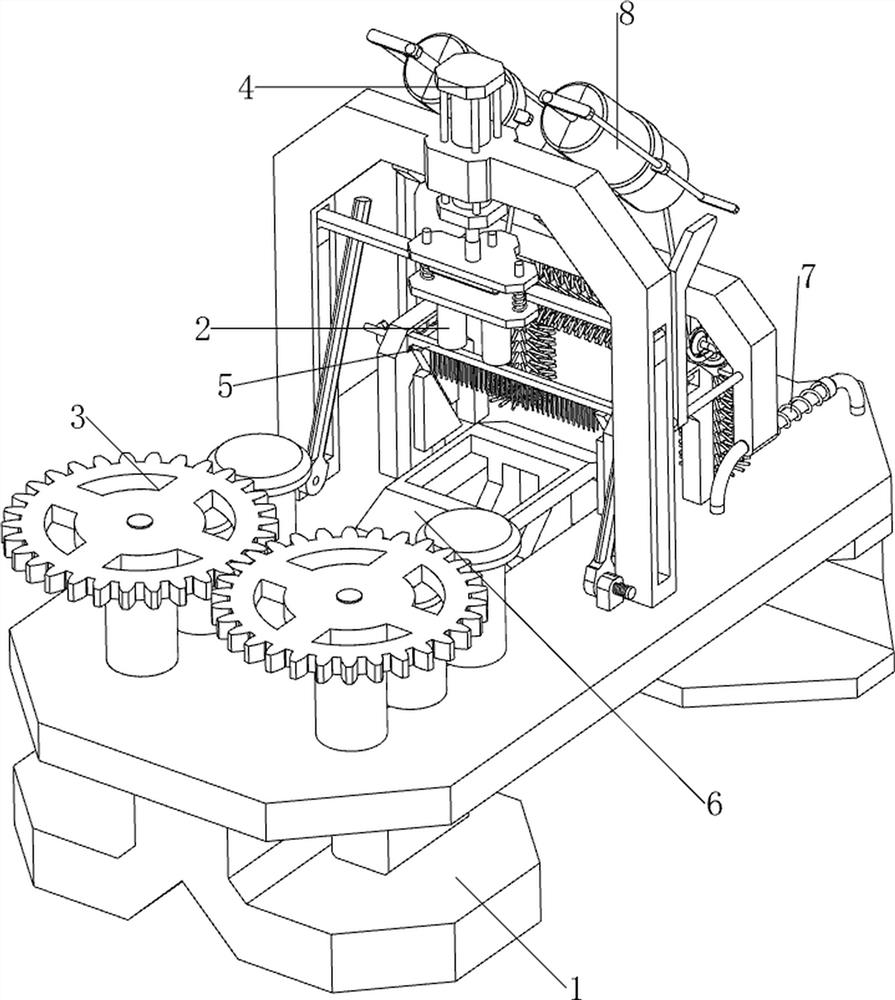

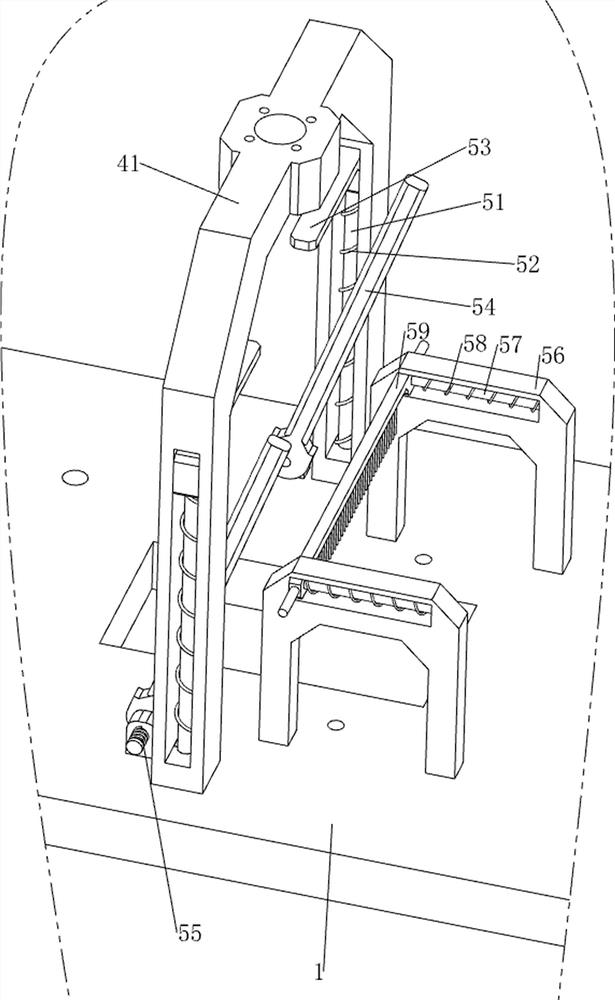

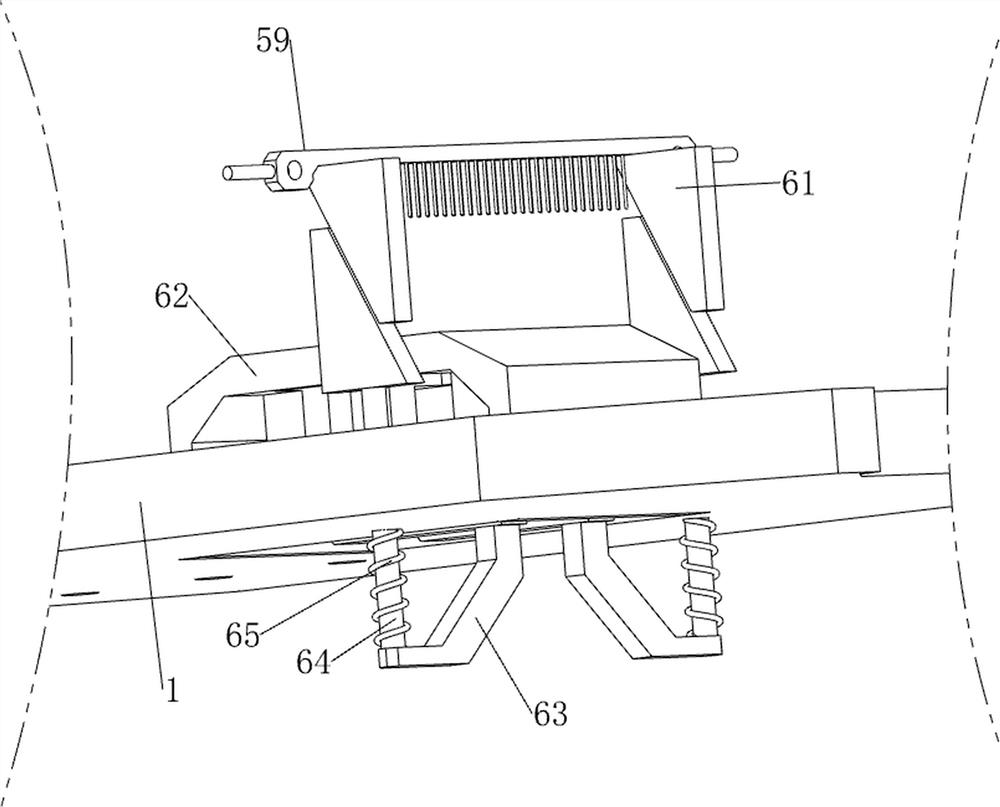

[0030] Such as Figure 1-7 A special-shaped steel pipe processing device for municipal building materials is shown, including a support frame 1, a punching knife 2, a transmission mechanism 3, a first transmission wheel 31, a second transmission wheel 32, a pulley 33, a flat belt 34, and a servo motor 35 , bevel gear set 36, spur gear 37, press-down mechanism 4, first fixed mount 41, cylinder 42, first briquetting block 43, second briquetting block 44, first spring 45, cleaning mechanism 5, first guide rod 51 , the second spring 52, the first pressing rod 53, the rotating rod 54, the torsion spring 55, the second fixed frame 56, the second guide rod 57, the third spring 58, the first brush 59, the jacking mechanism 6, the wedge block 61, bump 62, connecting block 63, slide bar 64, fourth spring 65, smear mechanism 7, third guide rod 71, slider 72, fift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com