Patents

Literature

53results about How to "Eliminate manual handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automated condiment dispensing system

InactiveUS20050194396A1Simple meanEliminate manual handlingCoin-freed apparatus detailsLiquid transferring devicesEngineeringMechanical engineering

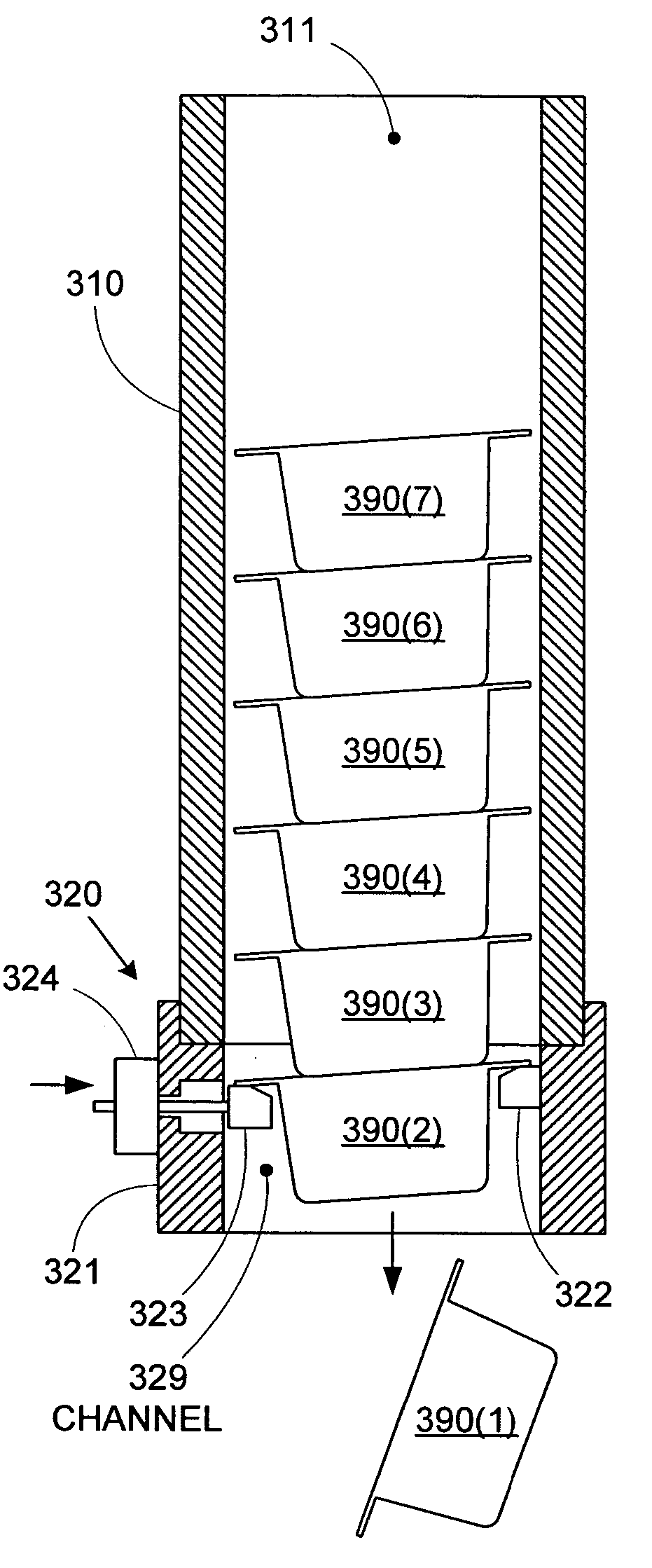

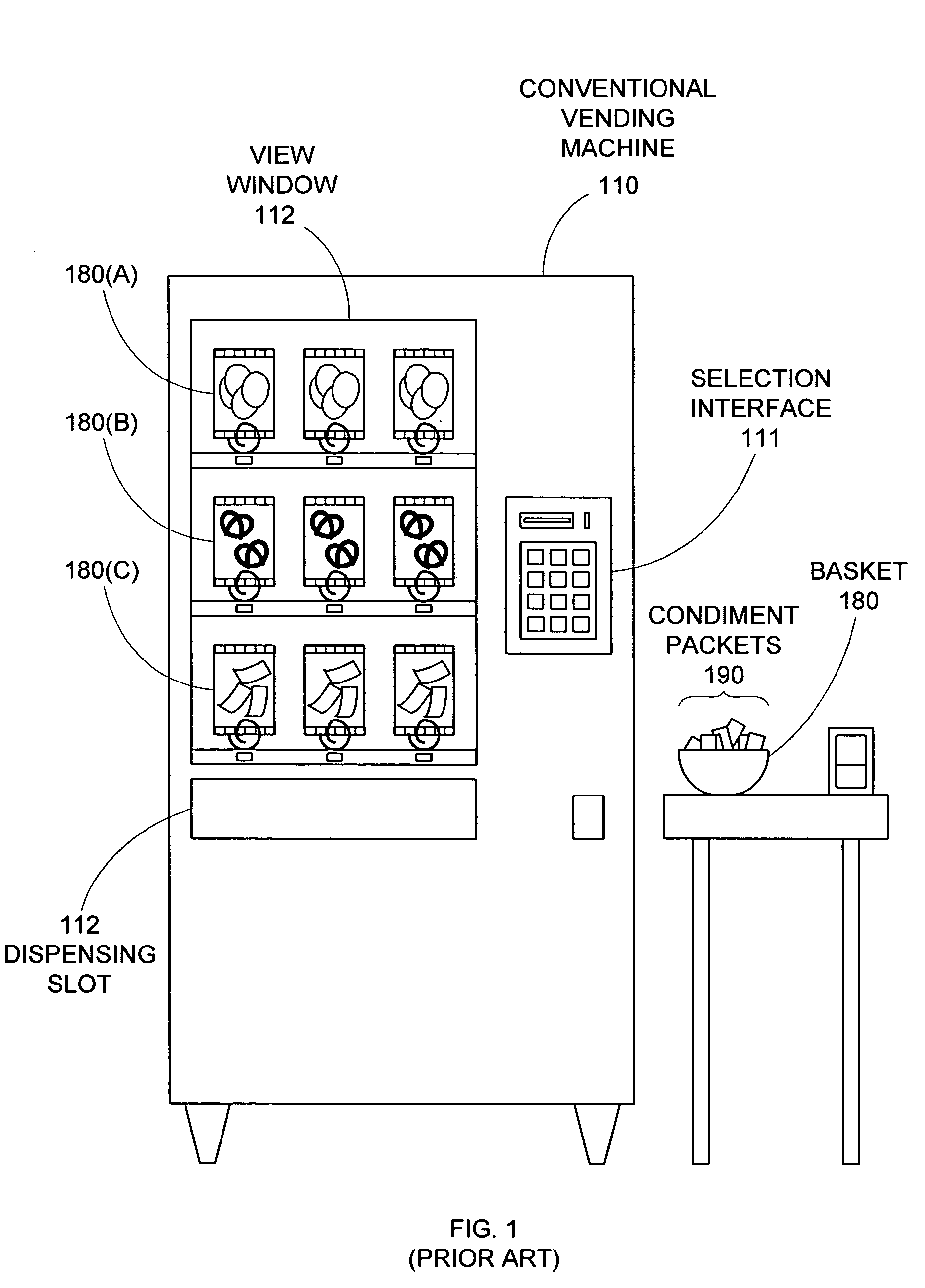

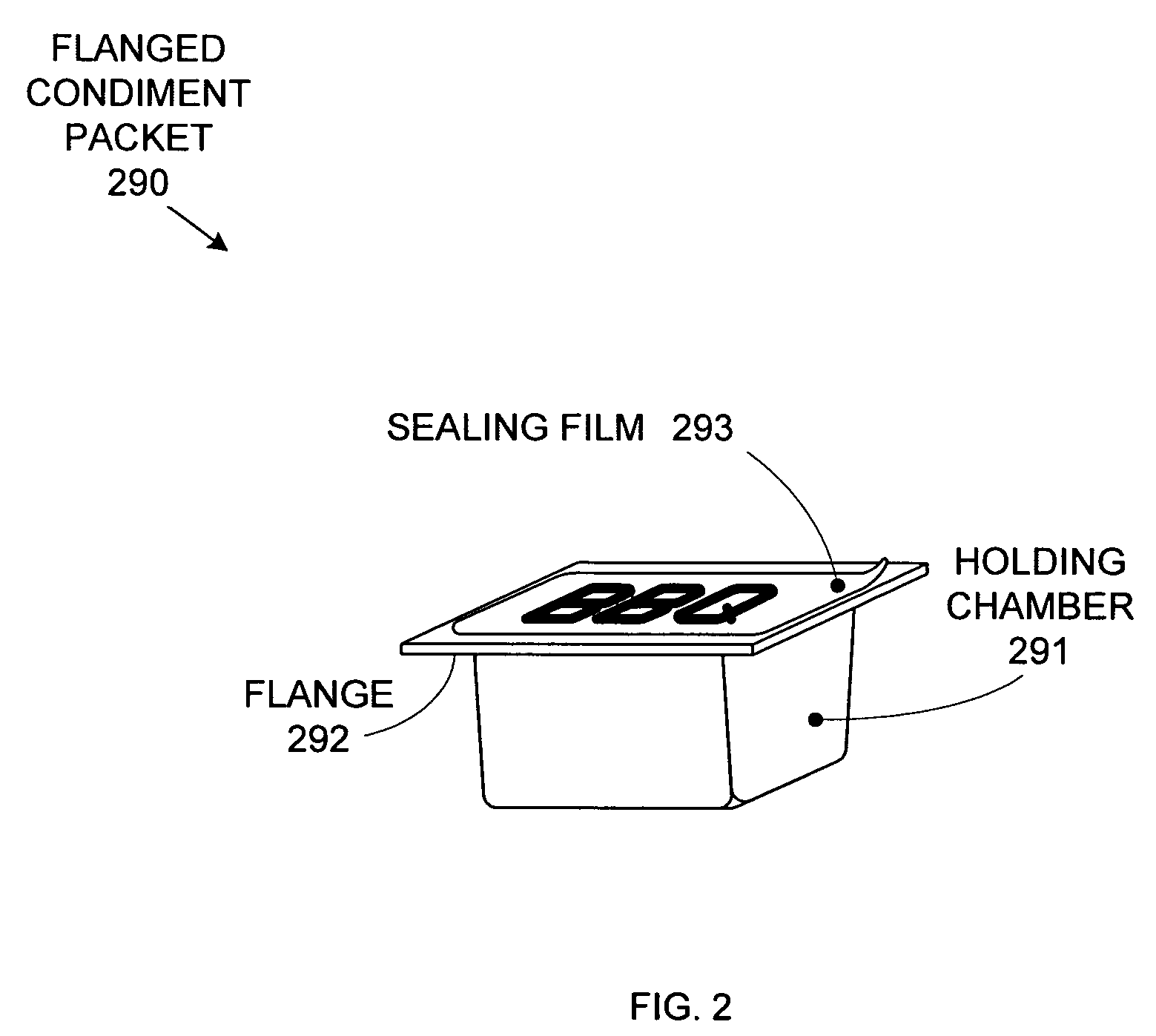

An automated system for dispensing condiment packets includes a magazine for storing a stack of condiment packets and a dispenser for metering out those condiment packets. Multiple magazines and dispensers can be combined in a single condiment delivery assembly, thereby providing the means for dispensing a variety of condiment flavors. The delivery assembly can be incorporated into a fast food vending machine or can be designed as a standalone unit.

Owner:EXPENSE MANAGEMENT

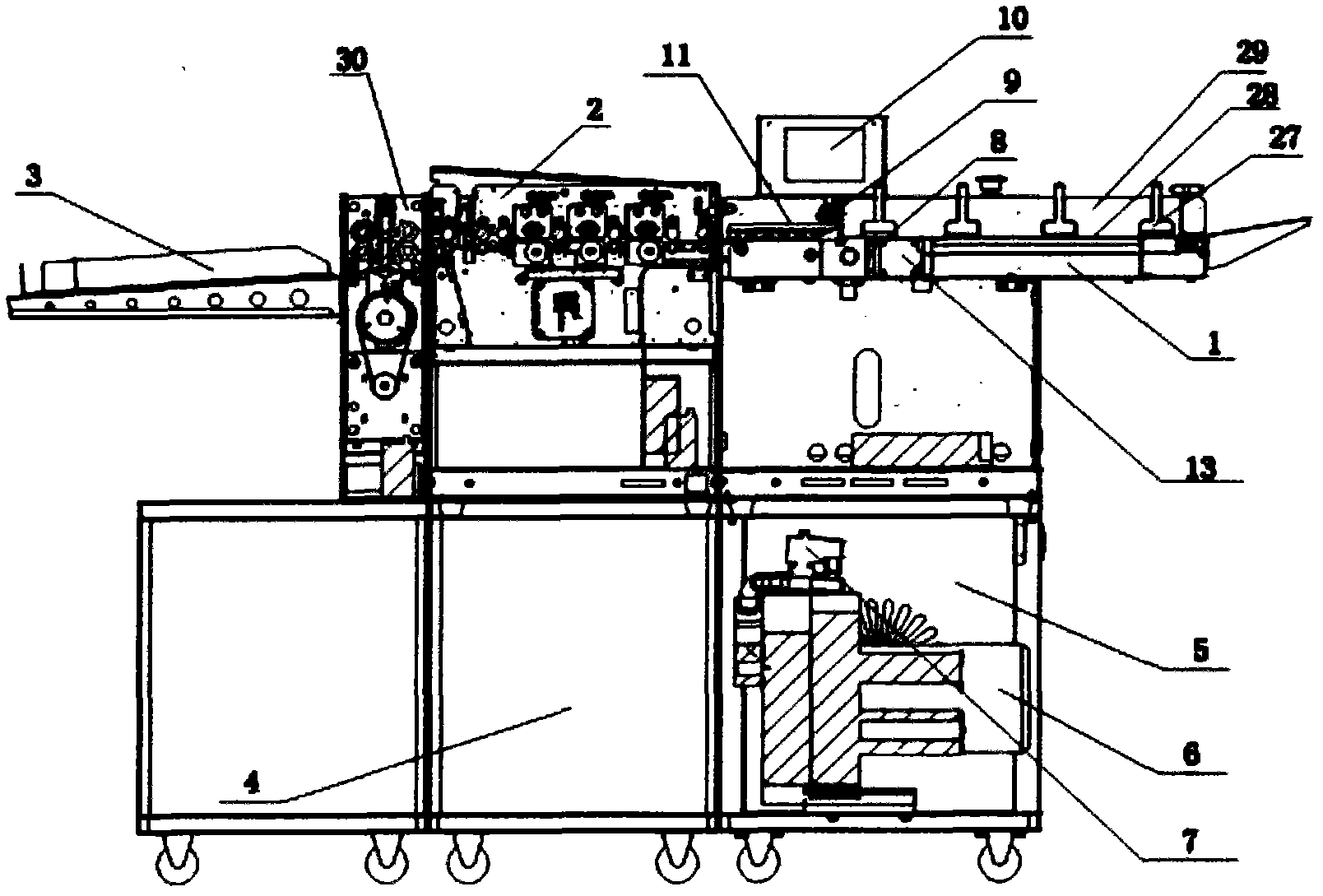

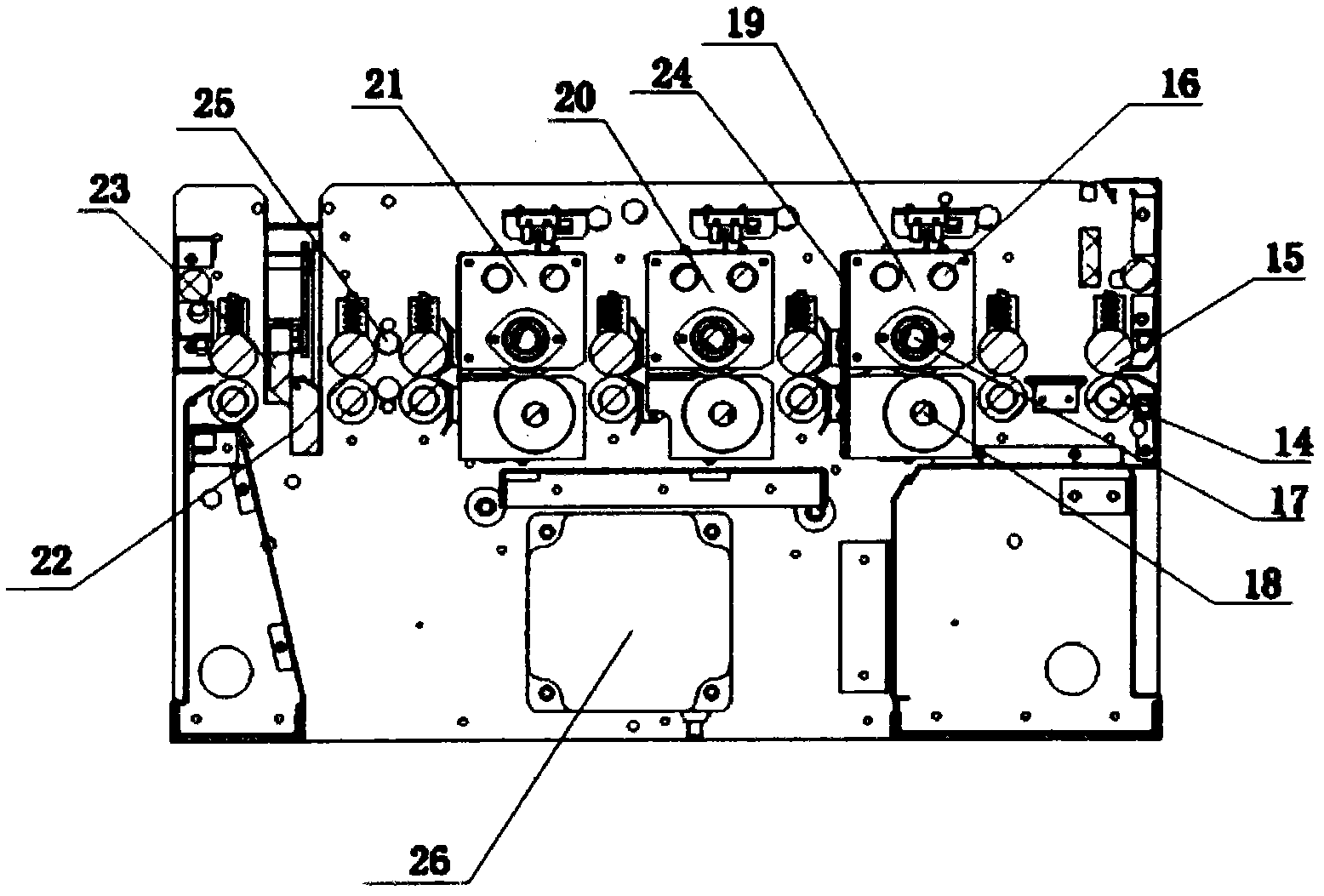

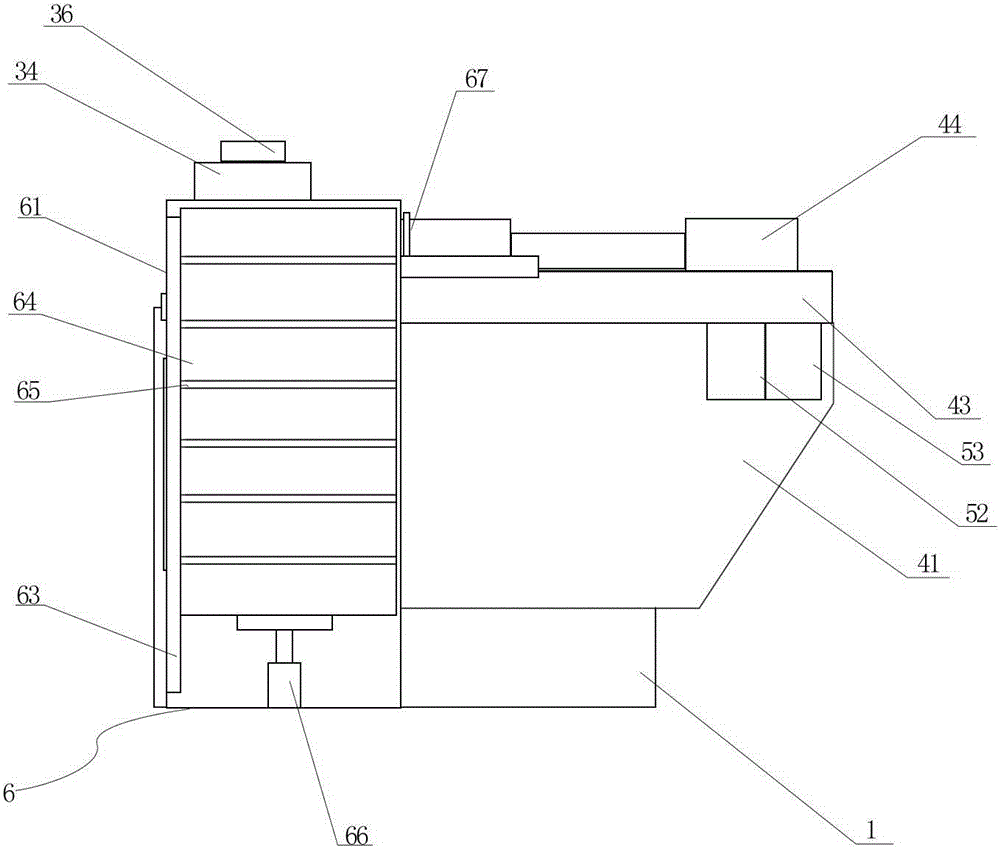

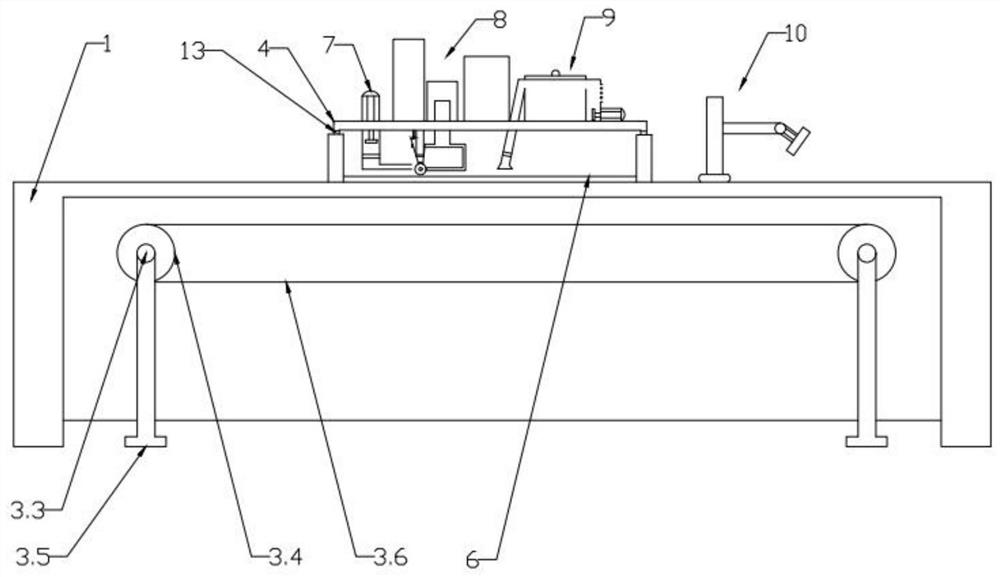

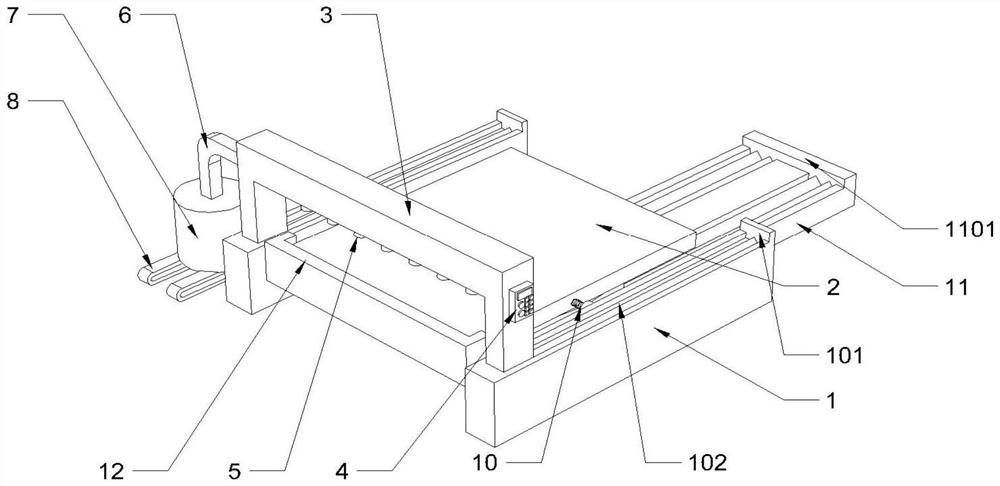

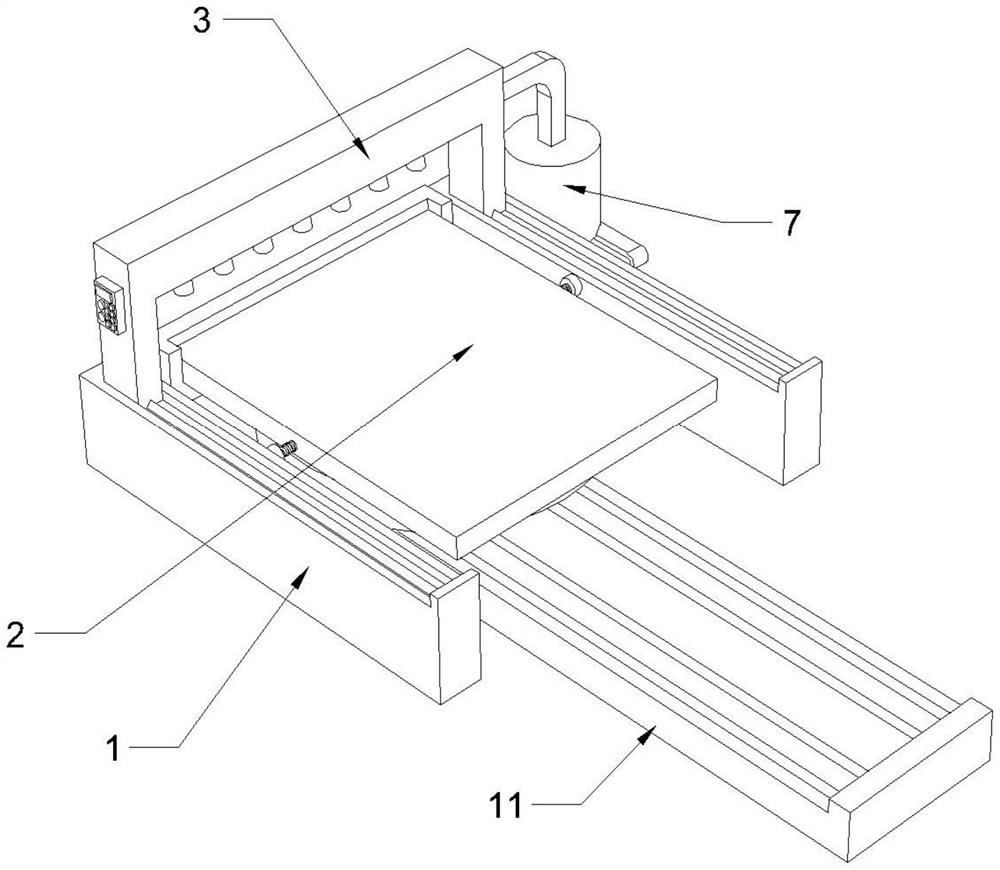

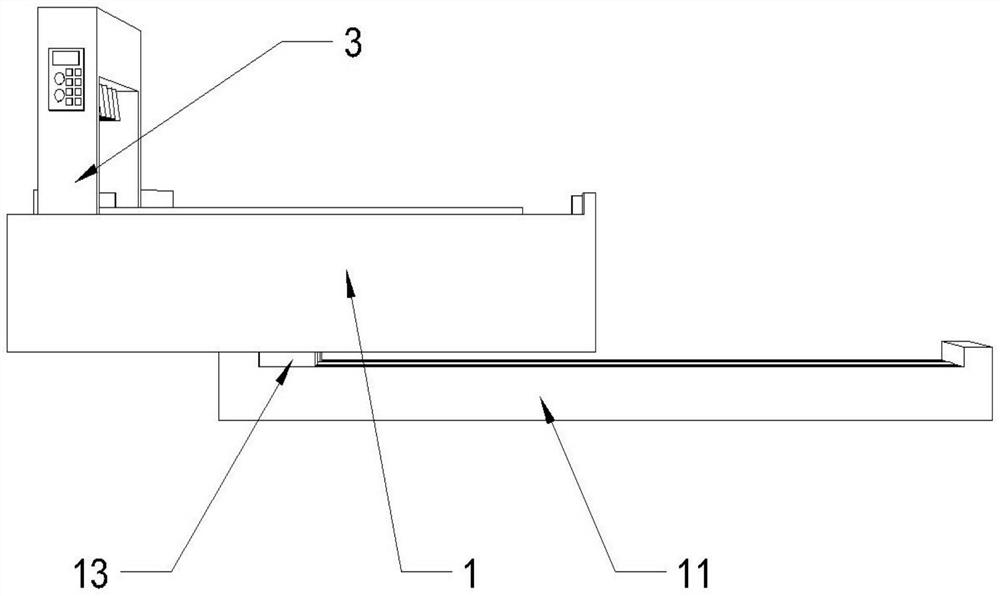

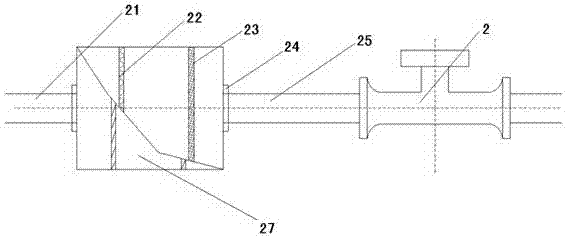

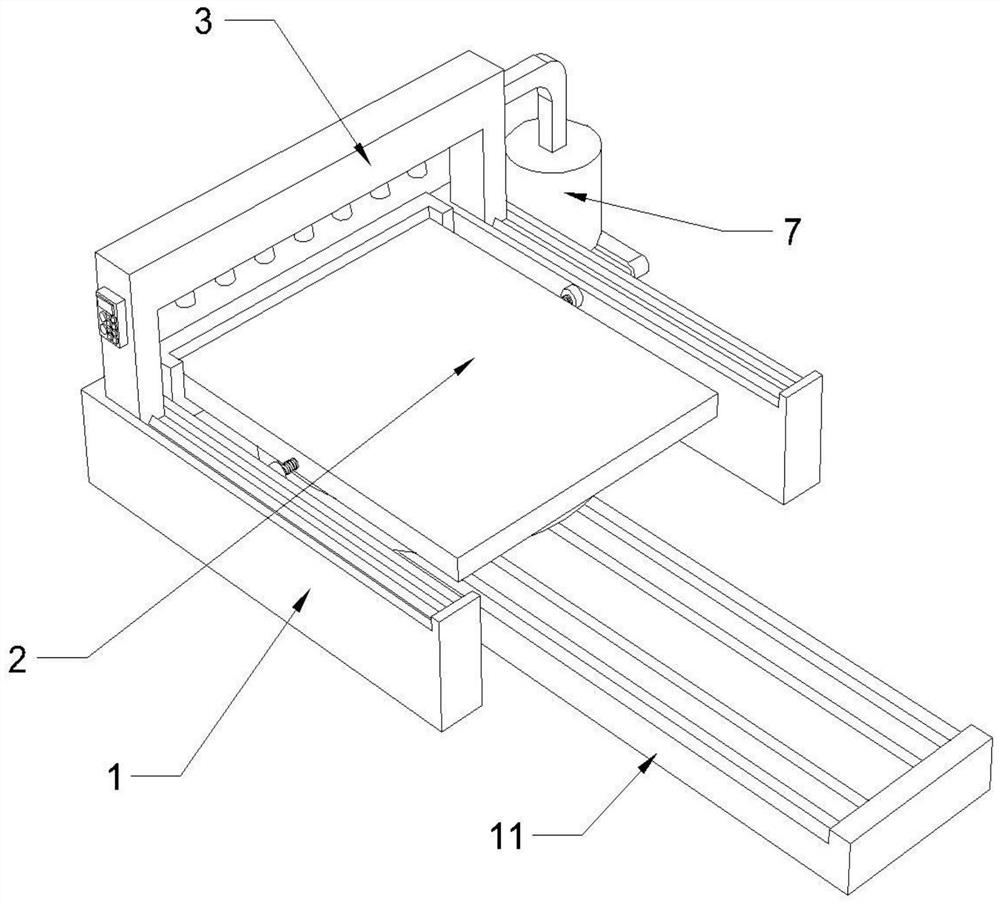

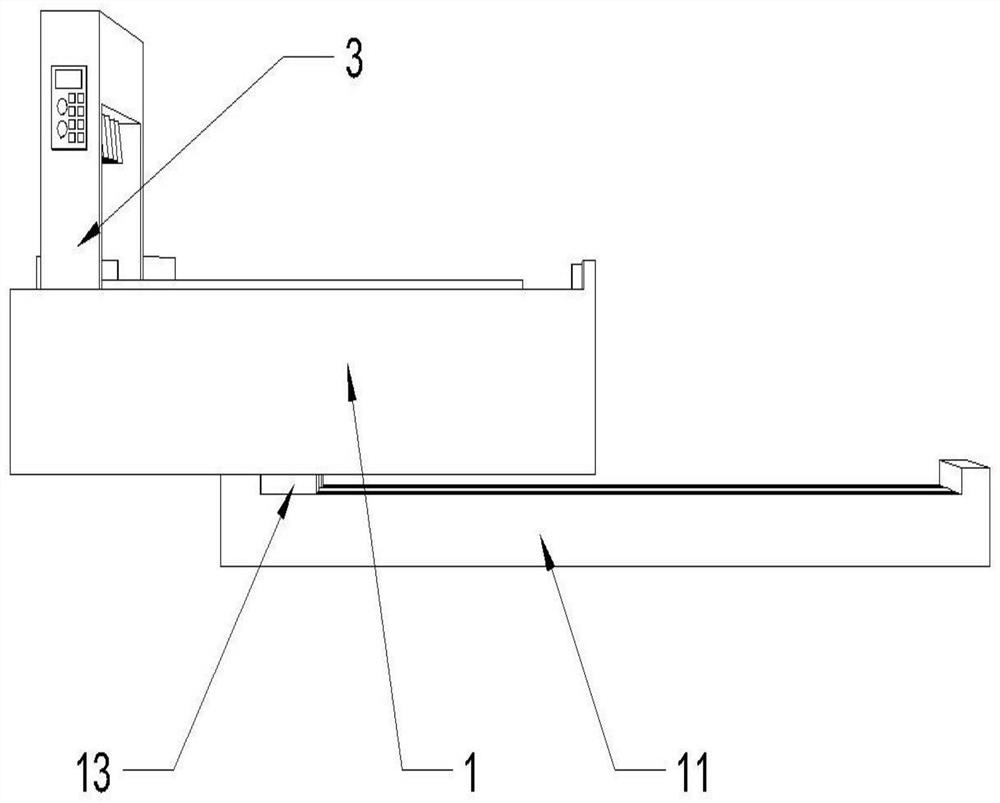

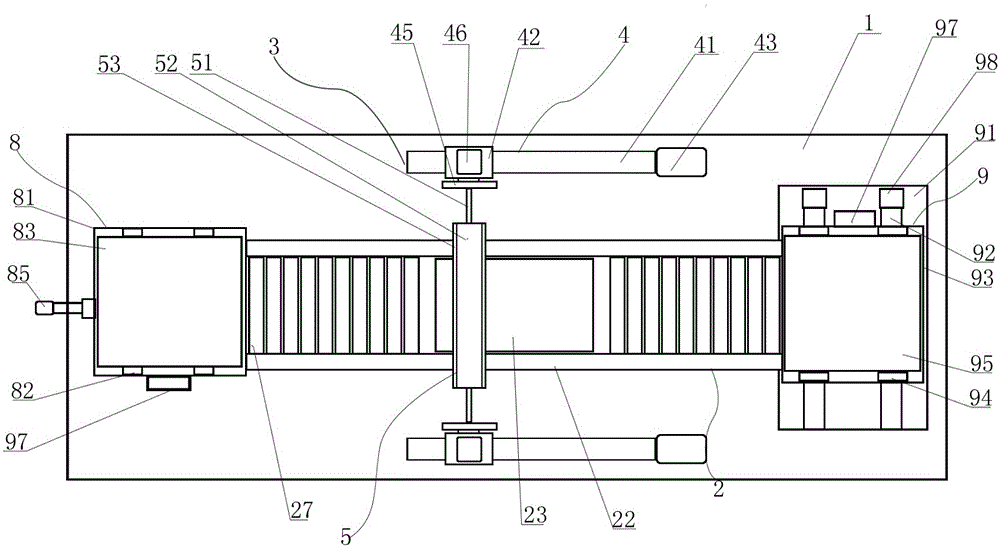

Automatic paper feed digital cropping and creasing machine

ActiveCN102922775AIncrease productivityFully automatedBox making operationsPaper-makingEconomic benefitsComputer module

The invention discloses an automatic paper feed digital cropping and creasing machine. The cropping and creasing machine comprises a paper feed unit, a paper receiving unit, a cropping module, a creasing unit, a type area position and positioning information bar code scanning head, a fan unit and an operating control unit; the cropping module comprises a cropping unit and a support bottom cabinet unit; the creasing unit comprises upper and lower paper feed rubber rollers, creasing cutters, upper and lower paper discharge rubber rollers, paper feed and discharge sensors, and a step motor; the problems of low efficiency and high cost in the conventional process for manufacturing a die cut template can be solved, and the production efficiency of a user is greatly; and the function of feeding paper without halting can be realized, the applicability and the production continuity of the machine are improved, the processing information bar codes are read and automatically adjusted, the effects of unattended operation, high yield and low labor cost can be achieved, and extremely high economic benefit is brought to the user.

Owner:GUANGZHOU DUMOR AUTOMATION SYST

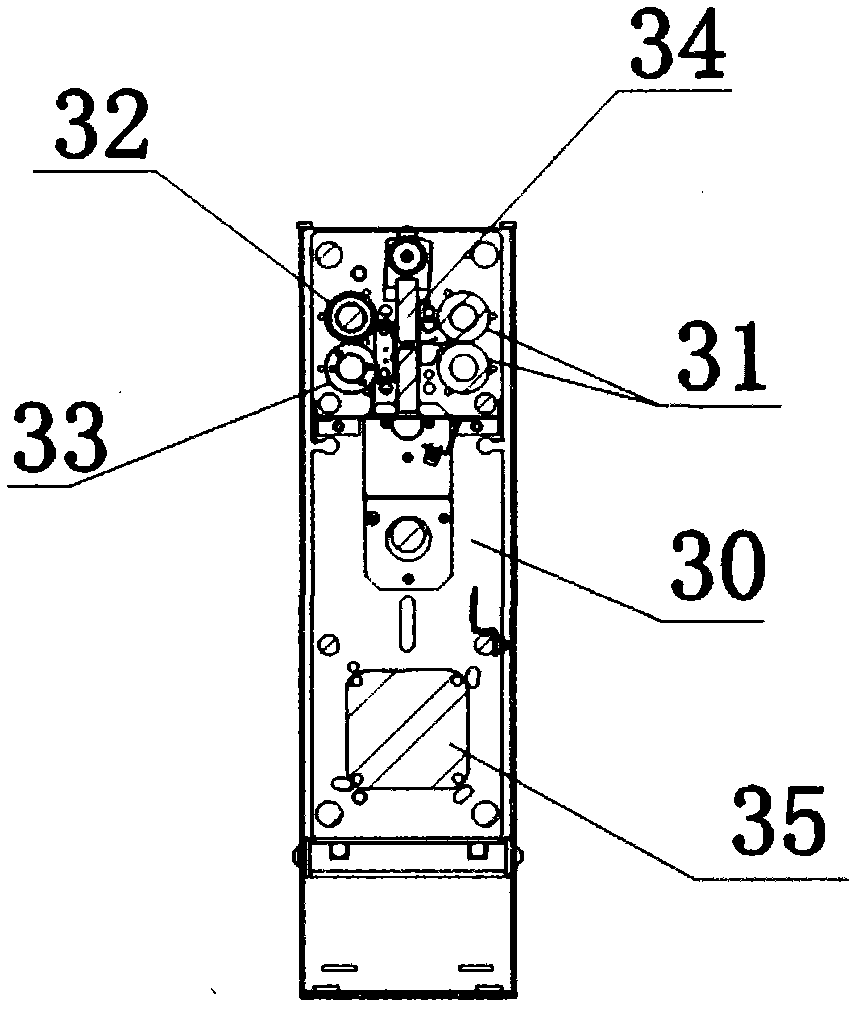

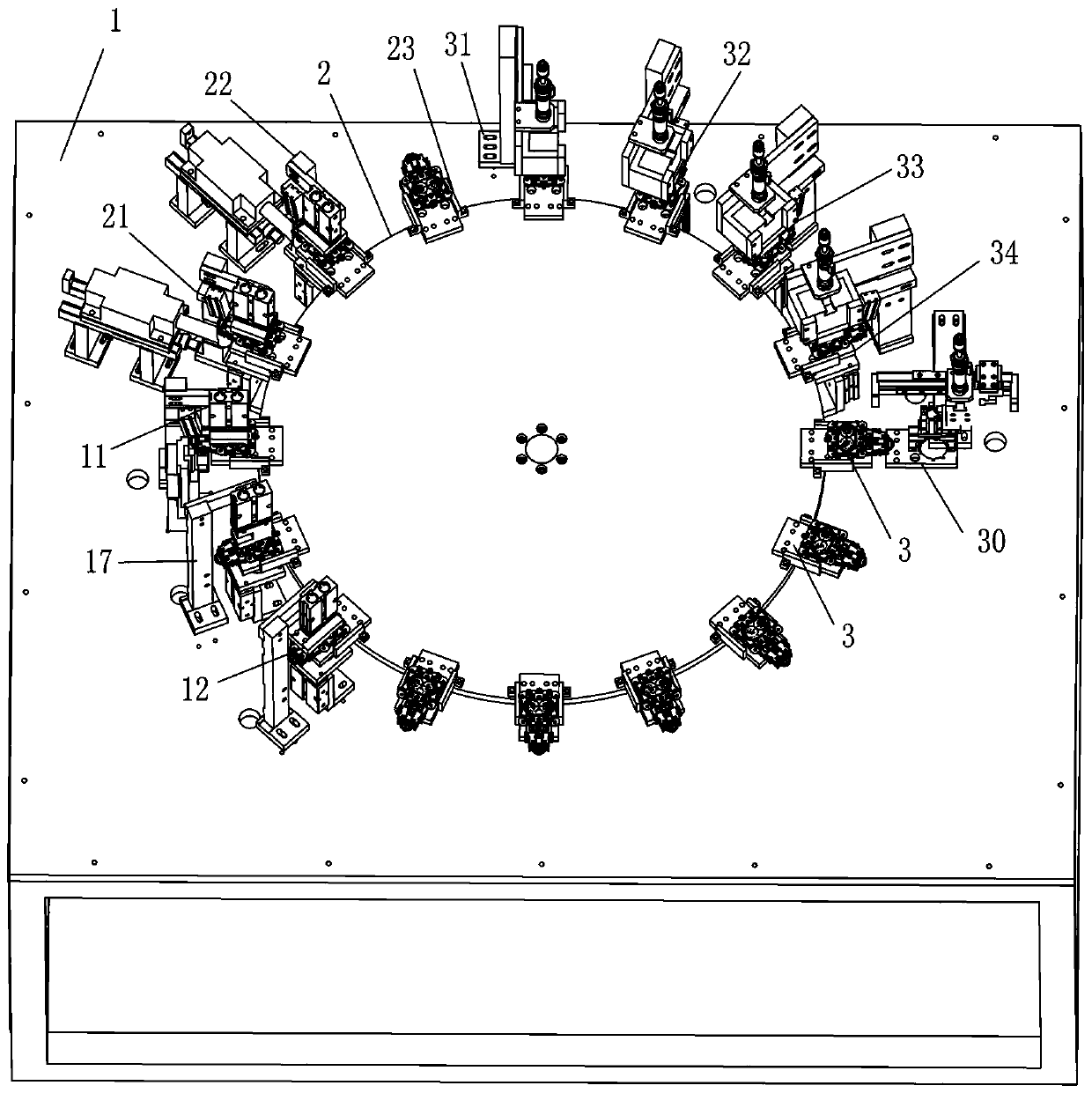

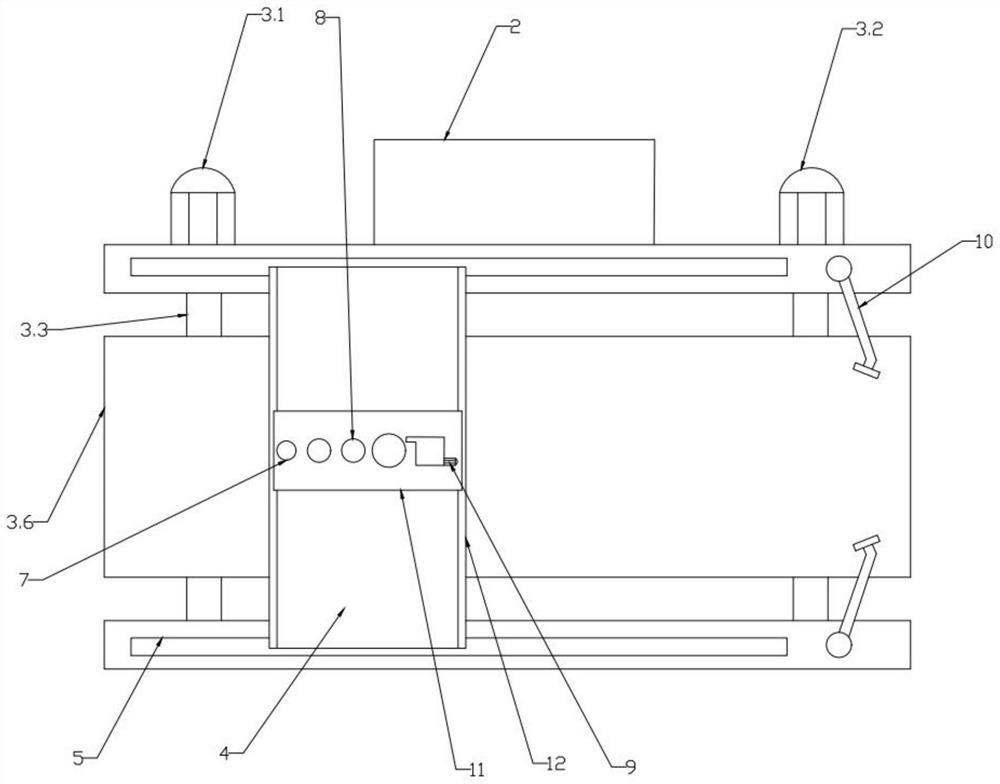

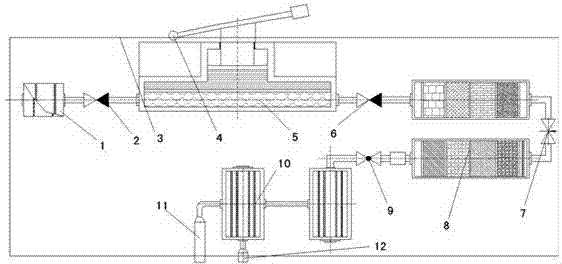

Bag-feeding-type vacuum packaging machine

InactiveCN104276306AIncrease production speedEliminate manual handlingPackaging under vacuum/special atmospherePumping vacuumWaste product

The invention discloses a bag-feeding-type vacuum packaging machine. The bag-feeding-type vacuum packaging machine is characterized by comprising a single turnplate, a bag feeding workstation, a bag opening workstation, a bag propping workstation, a charging workstation, a filling detection workstation, a point sealing workstation, a vacuum sealing workstation and a waste recovery workstation are uniformly distributed on the outer circumference of the single turnplate, a bag feeding device is arranged at the bag feeding workstation corresponding, a horizontal bag feeding mechanism is arranged on the outer side of the bag feeding device, a bag opening device is arranged at the bag opening workstation correspondingly, a bag propping device is arranged at the bag propping workstation correspondingly, a charging device is arranged at the charging workstation correspondingly, a detection device is arranged at the filling detection workstation correspondingly, a point sealing device is arranged at the point sealing workstation correspondingly, a centralized vacuumizing sealing device is arranged at the vacuum sealing workstation correspondingly and externally connected with a finished product output platform, and a waste product output platform is arranged at the waste recovery workstation correspondingly. The bag-feeding-type vacuum packaging machine can replace three independent devices for conventional unit-type vacuum packaging and is simple in structure, and speed, for vacuum packaging, of the bag-feeding-type vacuum packaging machine is increased.

Owner:RUIAN RUIZHI MACHINERY

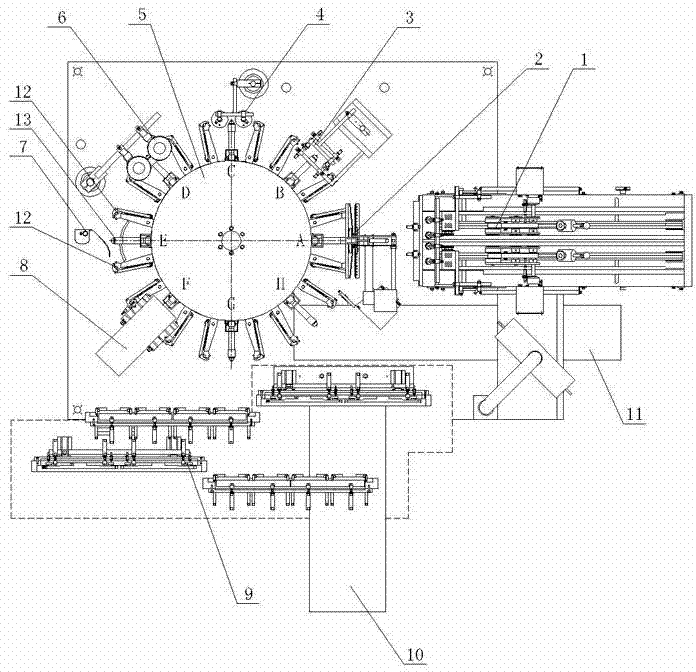

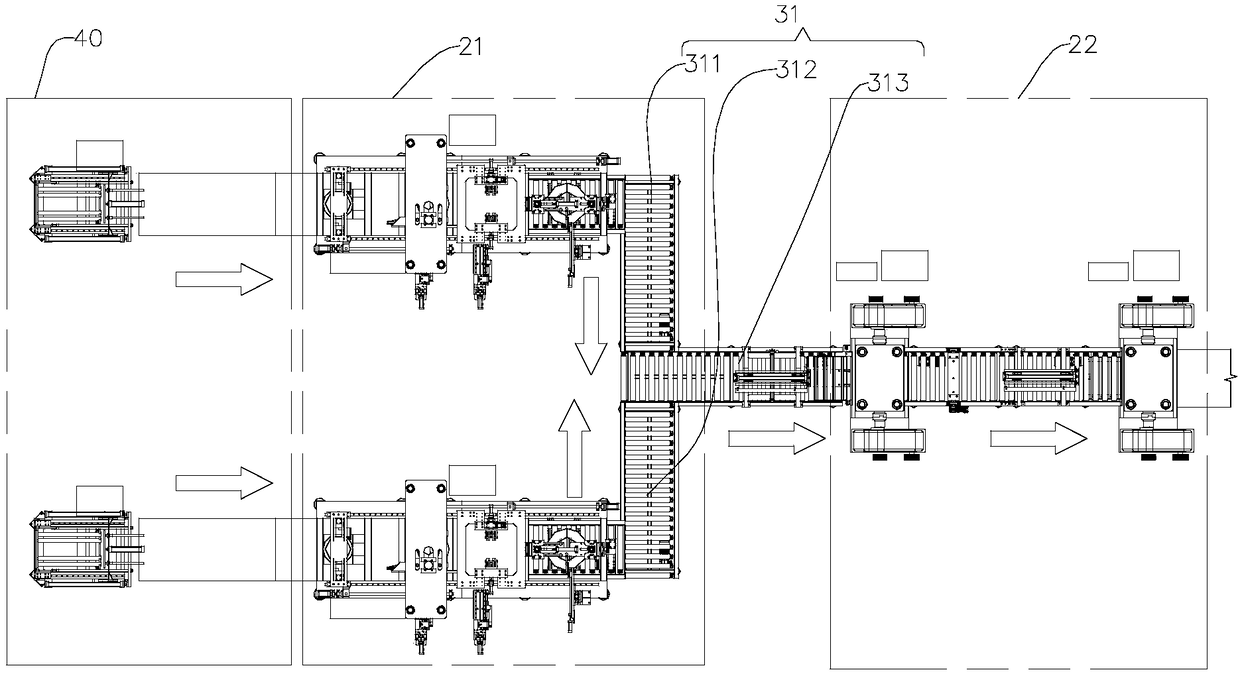

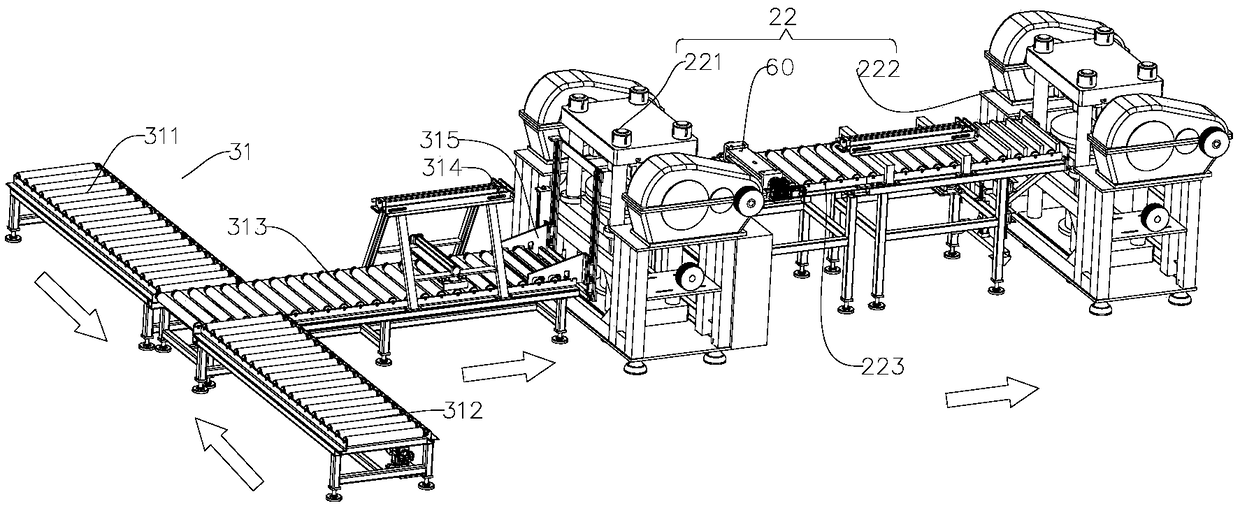

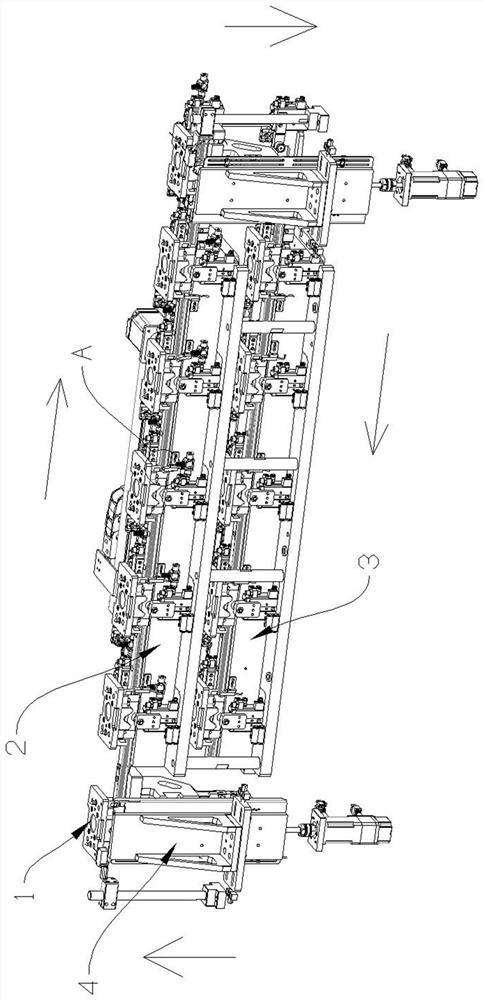

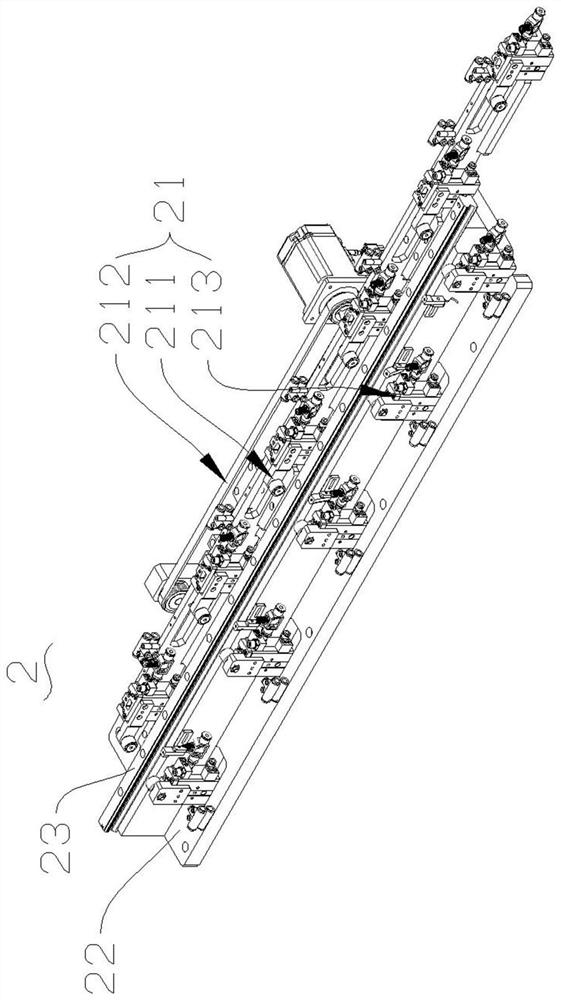

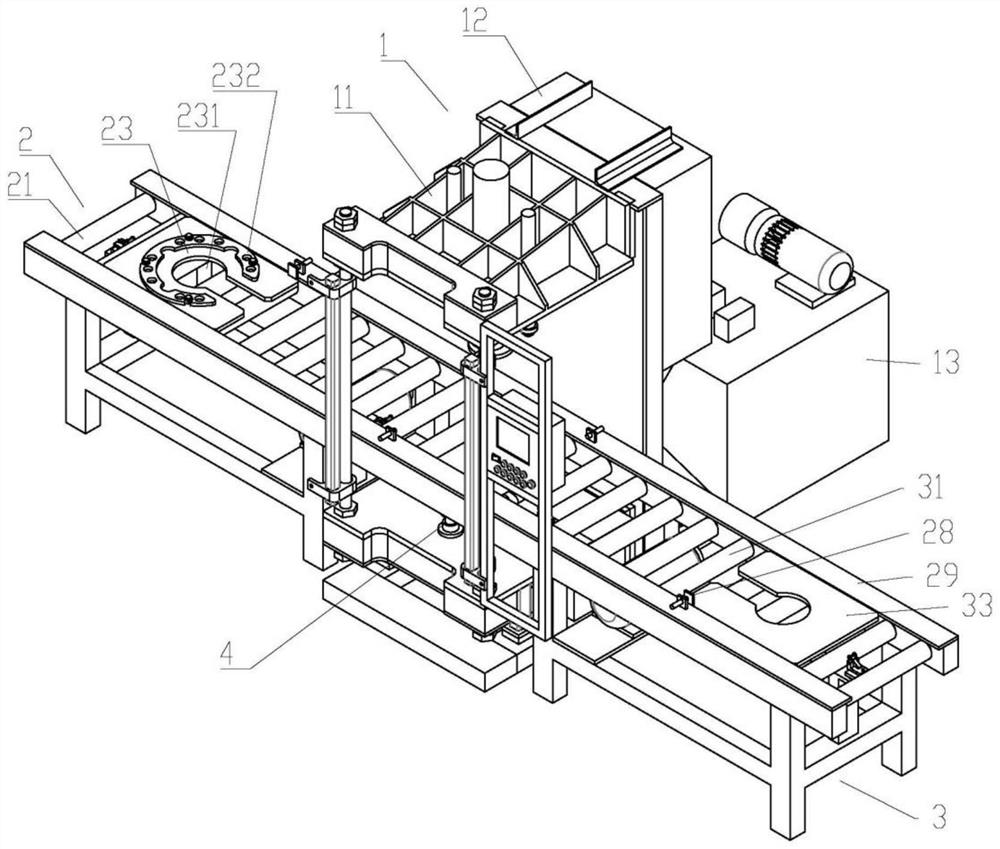

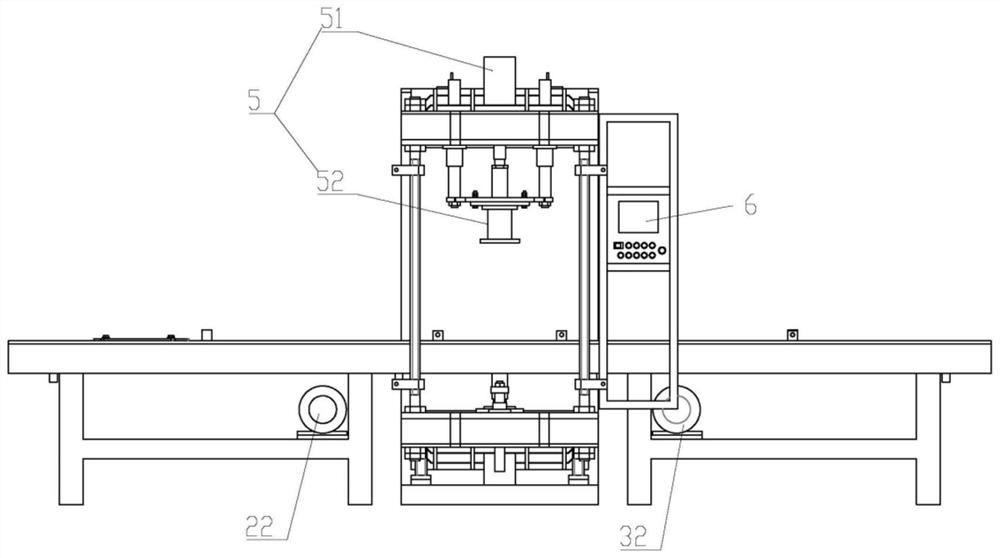

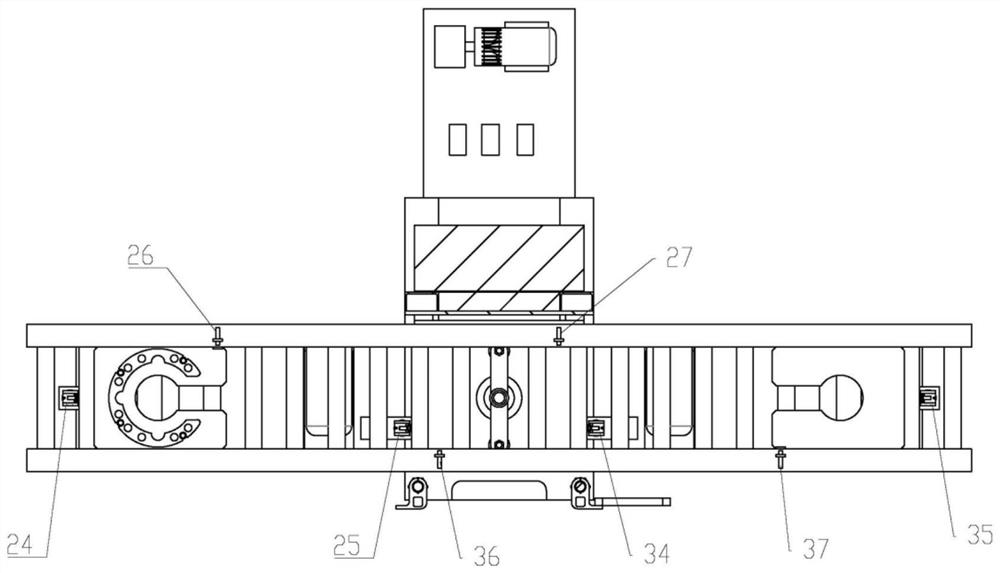

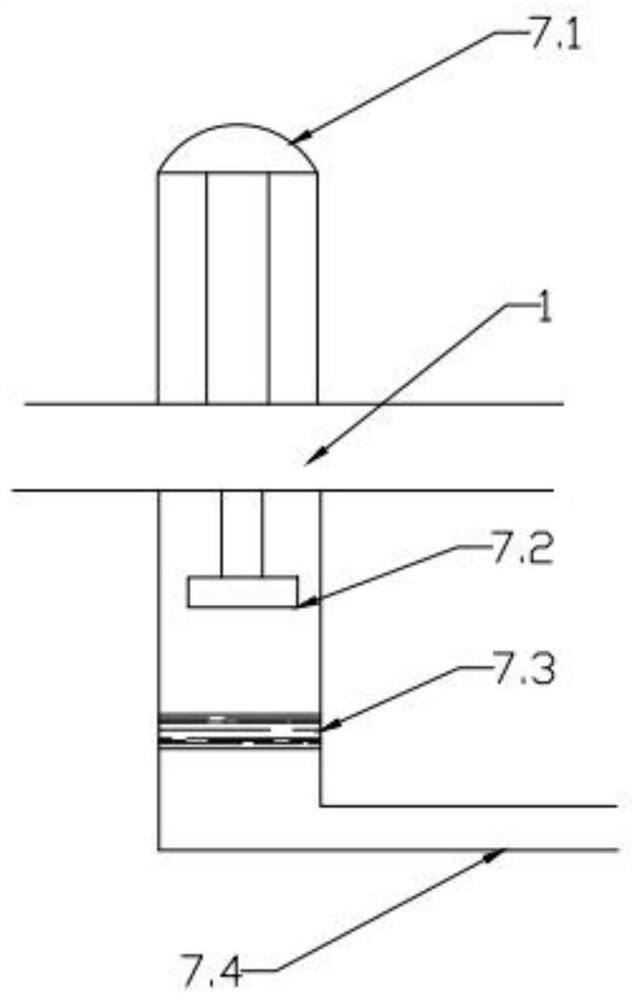

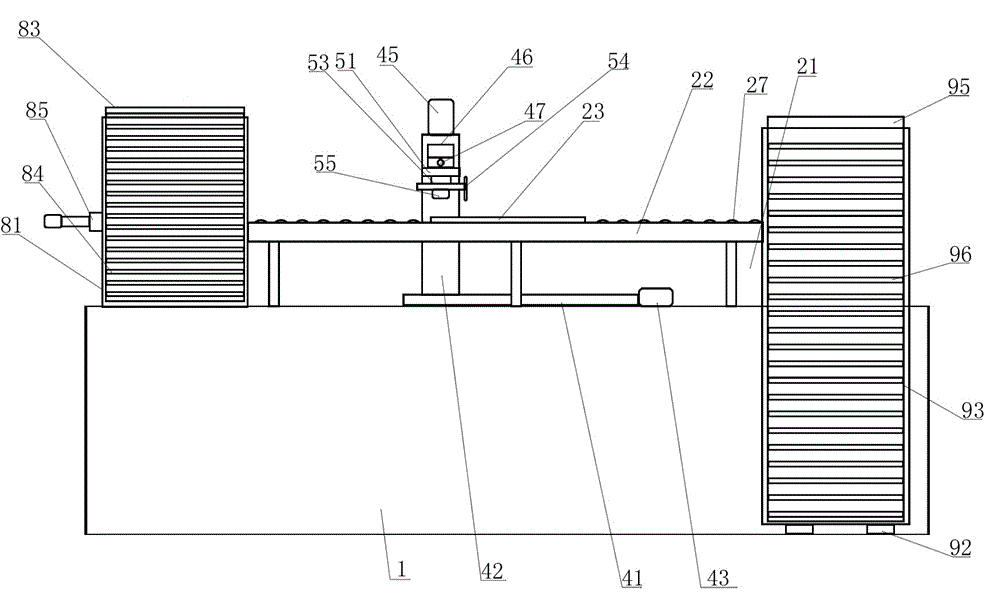

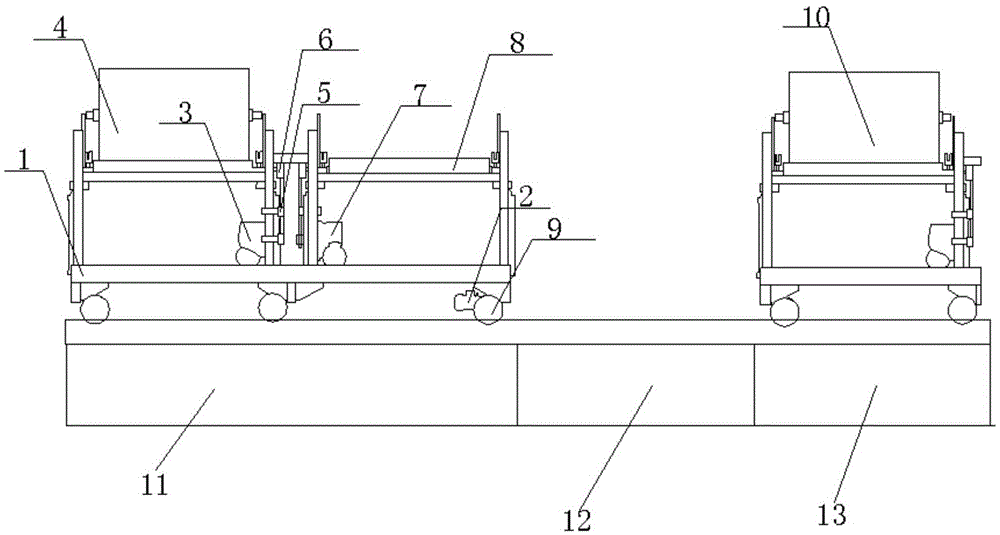

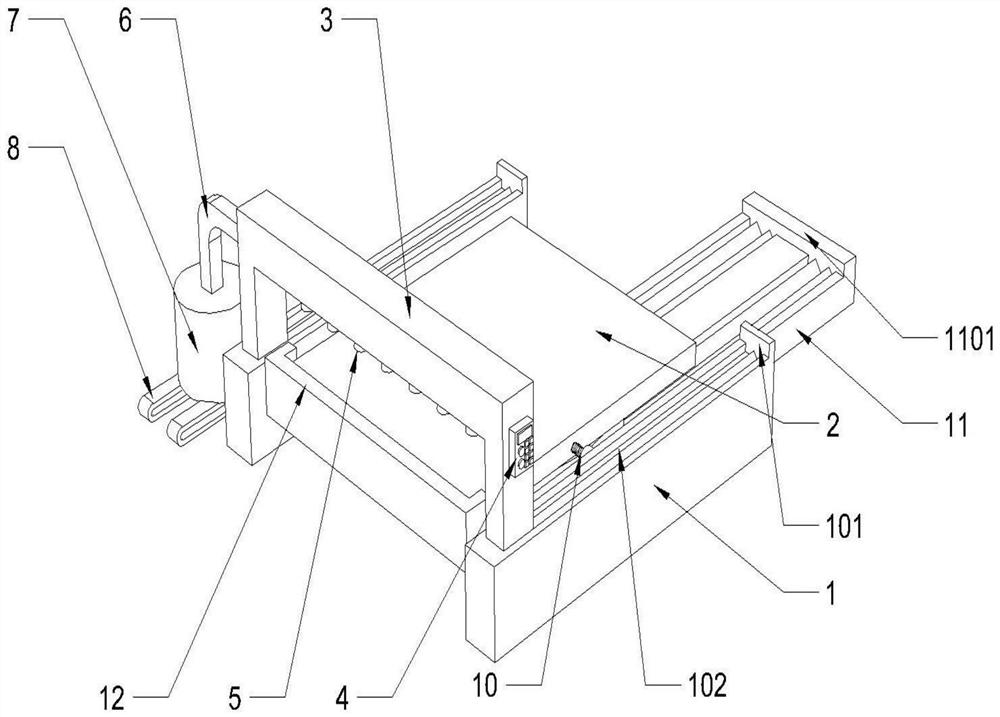

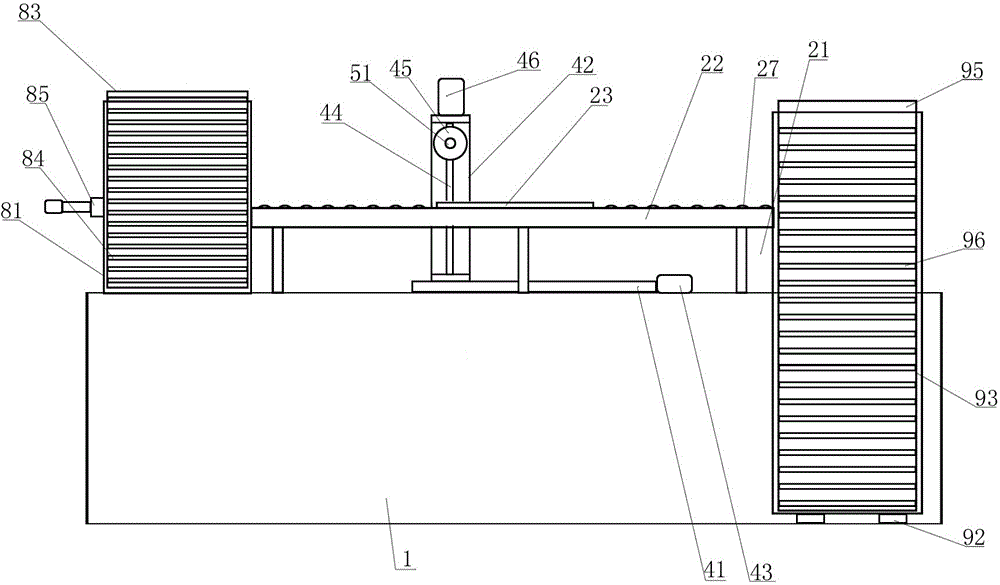

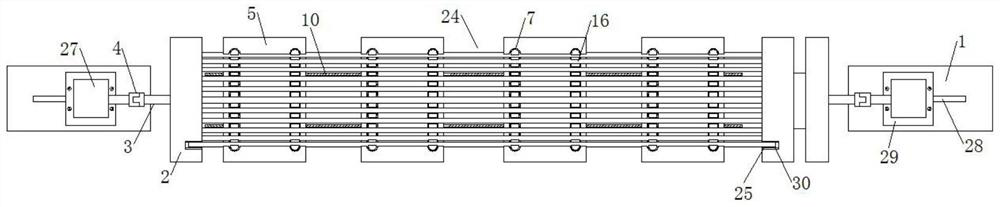

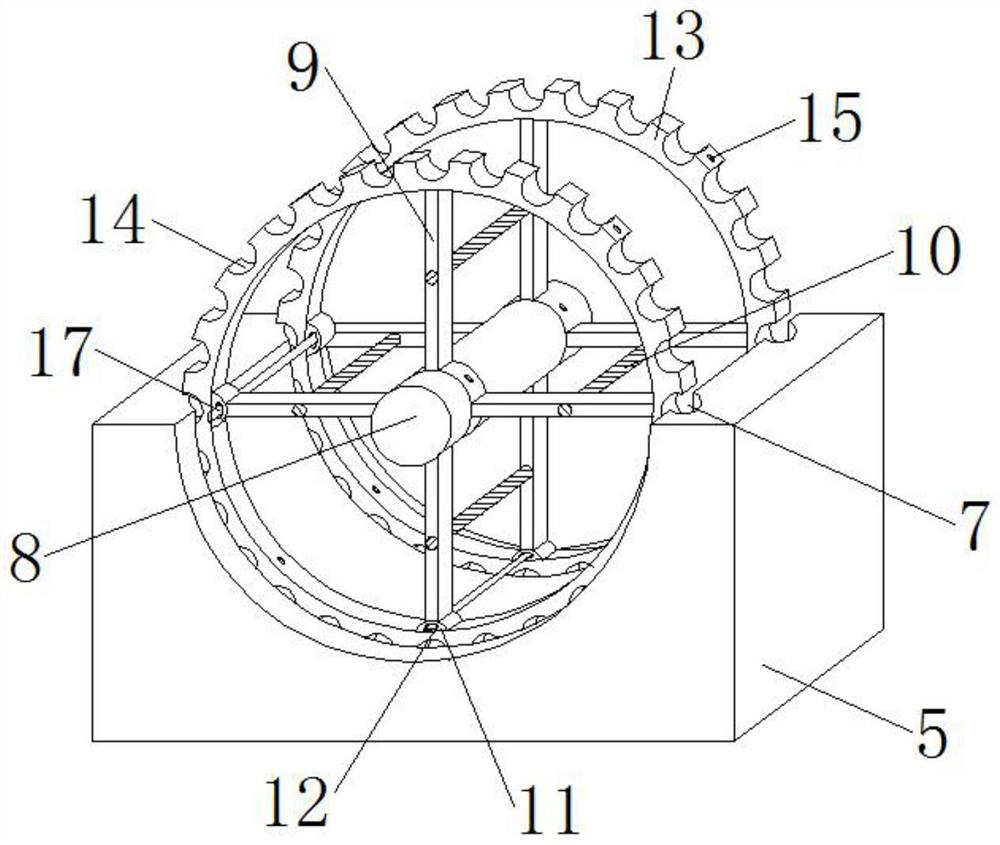

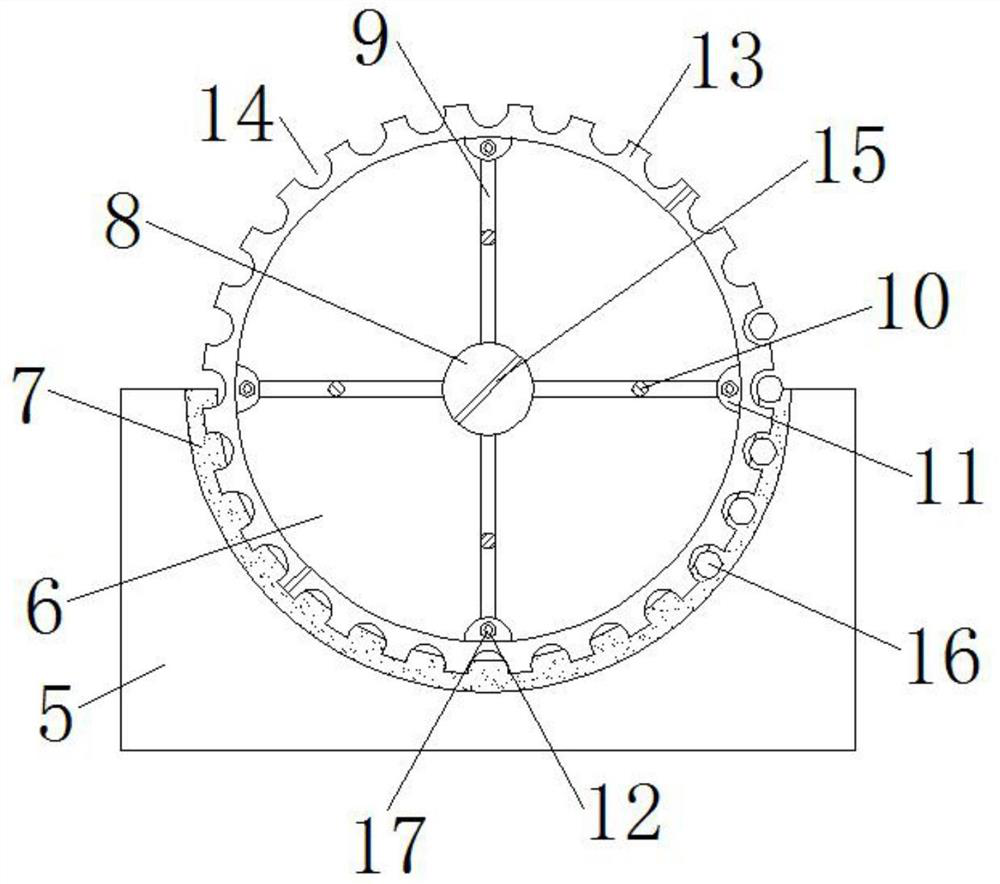

Welding, spin-leveling and end plate processing assembly line

PendingCN109396867ASave man hoursImprove processing efficiencyOther manufacturing equipments/toolsMetal working apparatusPunch pressAssembly line

The invention discloses a welding, spin-leveling and end plate processing assembly line which comprises a welding unit, a spin-leveling unit, a turning-lathe unit, a first punching machine unit, a drilling and tapping unit and a second punching machine unit sequentially connected through a conveying device. The welding unit is used for welding a notch of an annular single chip so as to form an endplate workblank; the spin-leveling unit is used for spin-leveling the end plate workblank; the turning-lathe unit is used for turning the end plate workblank; the first punching machine unit is usedfor punching the end plate workblank; the drilling and tapping unit is used for drilling and tapping the end plate workblank; the second punching machine unit is used for punching the end plate workblank; and the conveying device is arranged to be a feeding end for conveying the end plate workblank at the discharging end of the previous unit to the feeding end of the next unit. Therefore, the labor hour spent on processing the annular single chip to be an end plate is reduced, and the processing efficiency of the end plate is improved; and the welding unit, the spin-leveling unit, the turning-lathe unit, the first punching machine unit, the drilling and tapping unit and the second punching machine unit are connected through the conveying device, so that manual handling can be avoided, thelabor intensity of an operator is reduced, and a semi-finished product has no need to be stored and managed.

Owner:GUANGZHOU DEYA MACHINERY MFG

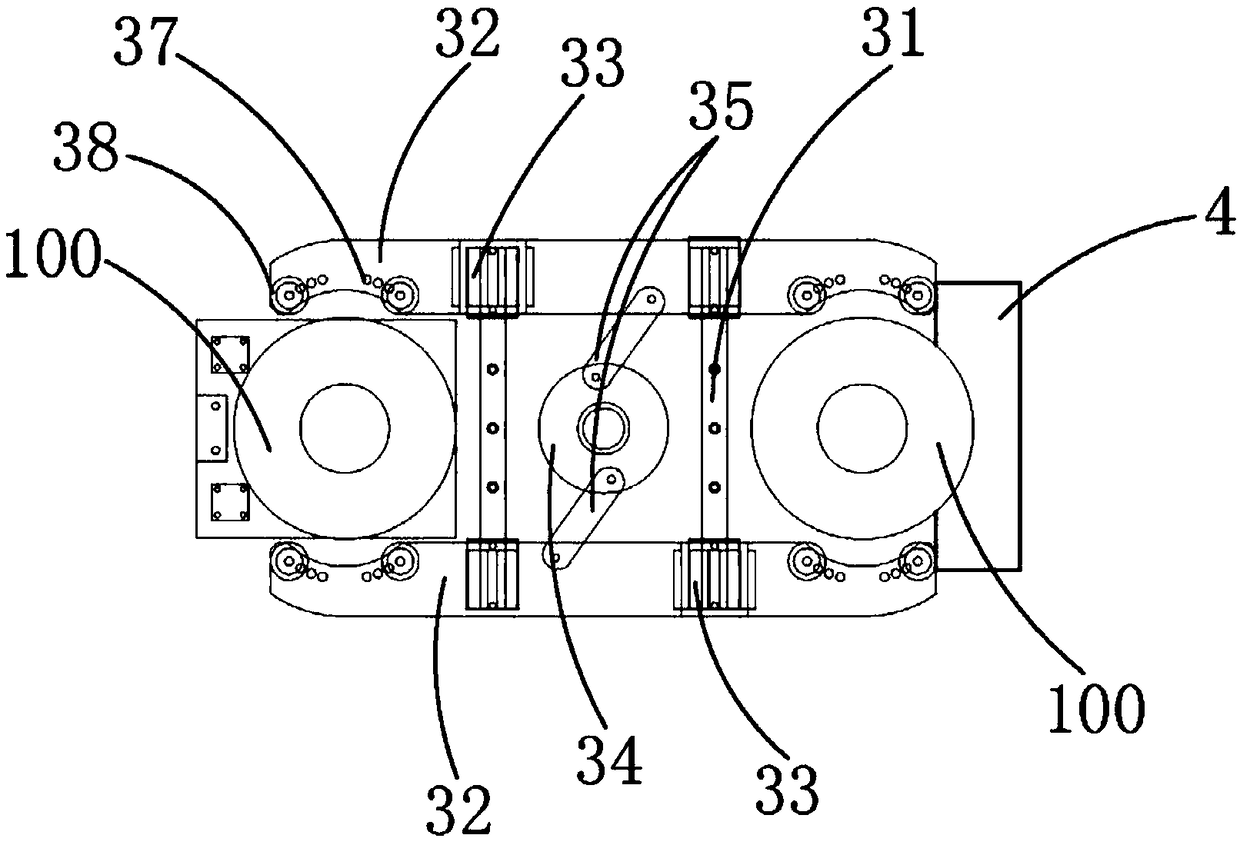

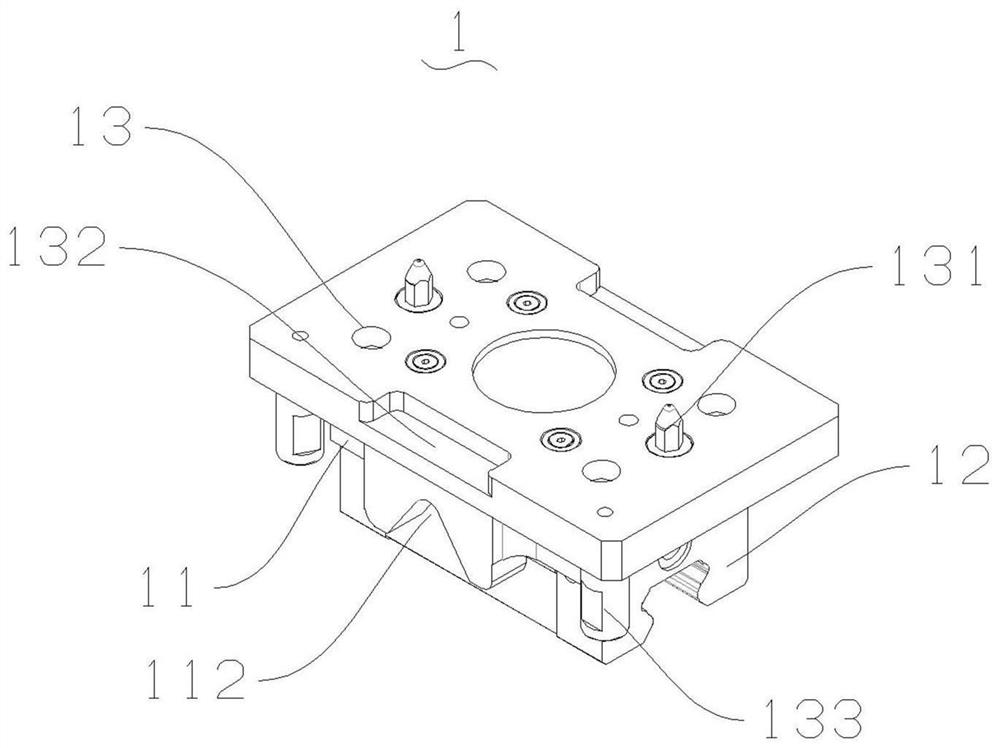

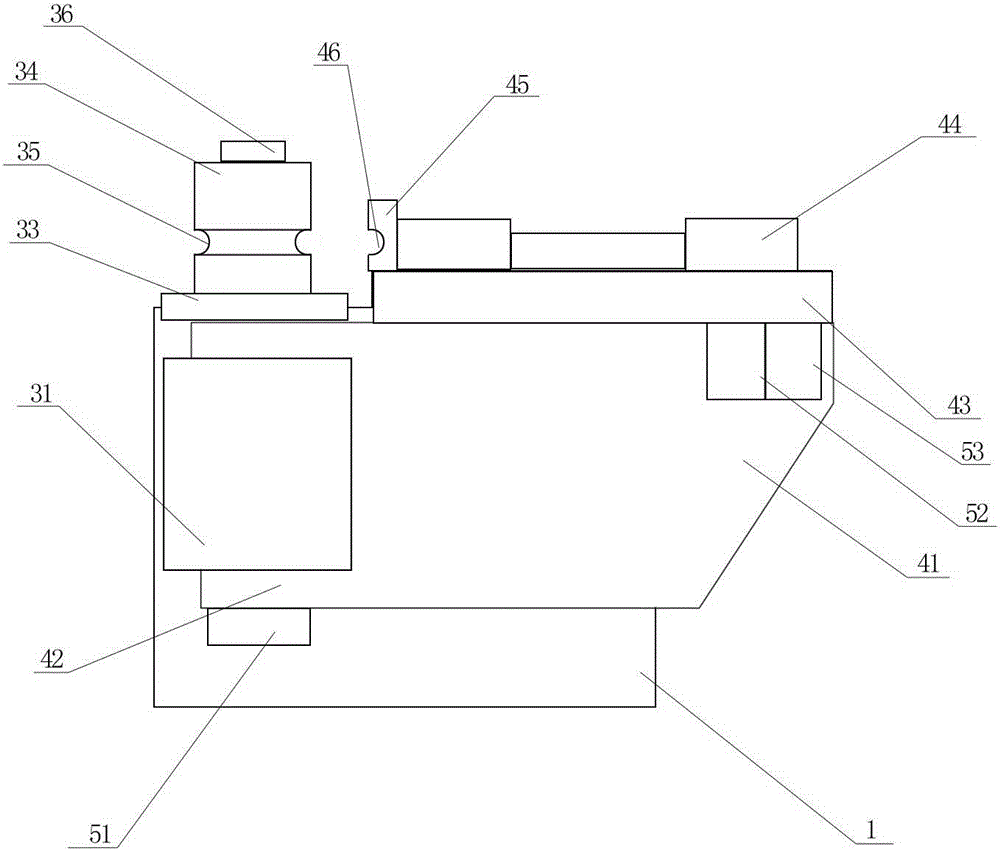

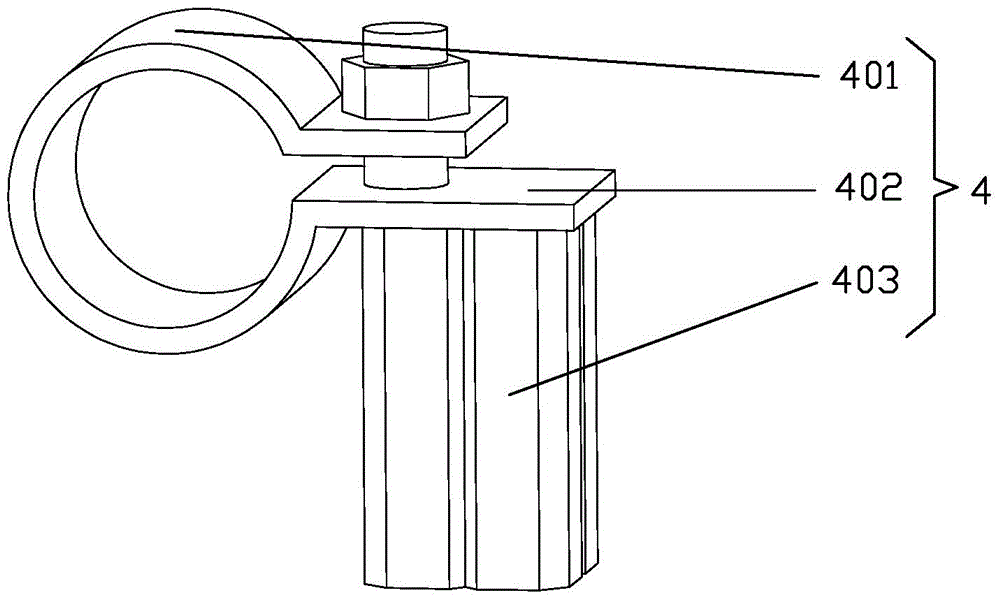

Ceramic forming mold automatic exchange machine

InactiveCN108724449AHigh degree of automationIncrease productivityConveyorsAuxillary shaping apparatusMaterials scienceAutomation

The invention relates to the field of ceramic forming production equipment, in particular to a ceramic forming mold automatic exchange machine. The ceramic forming mold automatic exchange machine is characterized by comprising a longitudinal moving mechanism, an exchange mechanism and a clamping mechanism; the longitudinal moving mechanism comprises a mold clamping rack, a longitudinal slide railfixedly arranged on the mold clamping rack, a longitudinal moving rack slidably arranged on the longitudinal slide rail and a longitudinal driving unit driving the longitudinal moving rack to move; the exchange mechanism comprises an exchange servo motor fixedly arranged on the longitudinal moving rack and a rotary frame driven by the exchange servo motor to rotate. According to the ceramic forming mold automatic exchange machine provided by the invention, rising, dropping, position exchange and clamping of plaster molds can be implemented through the longitudinal moving mechanism, the exchange mechanism and the clamping mechanism; unformed plaster molds on a production line and formed plaster mold on an automatic forming machine can be exchanged; the automation degree is high, manual carrying of molds is omitted; the production efficiency is improved; and the labor cost is lowered.

Owner:福建省德化博龙陶瓷有限公司

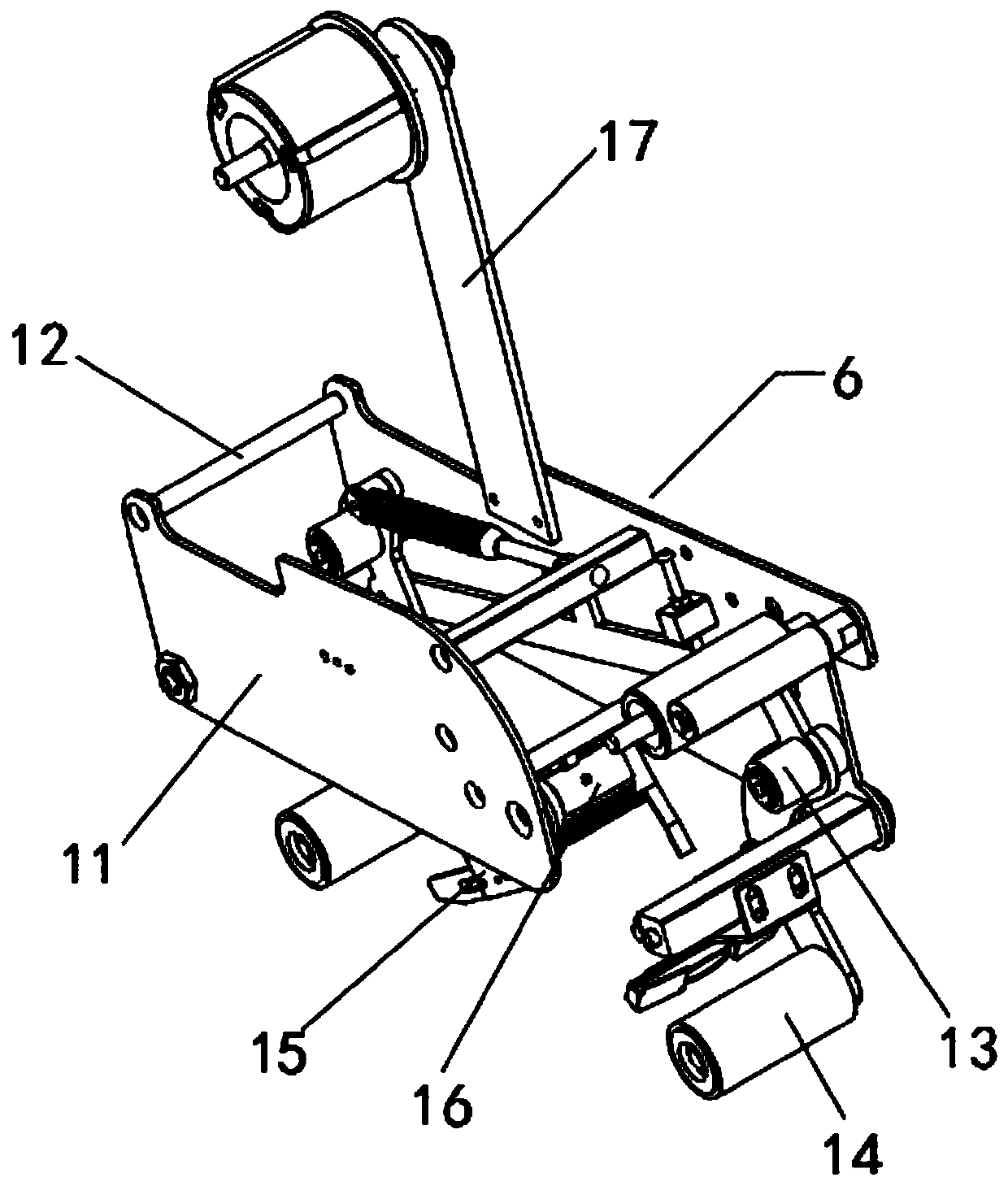

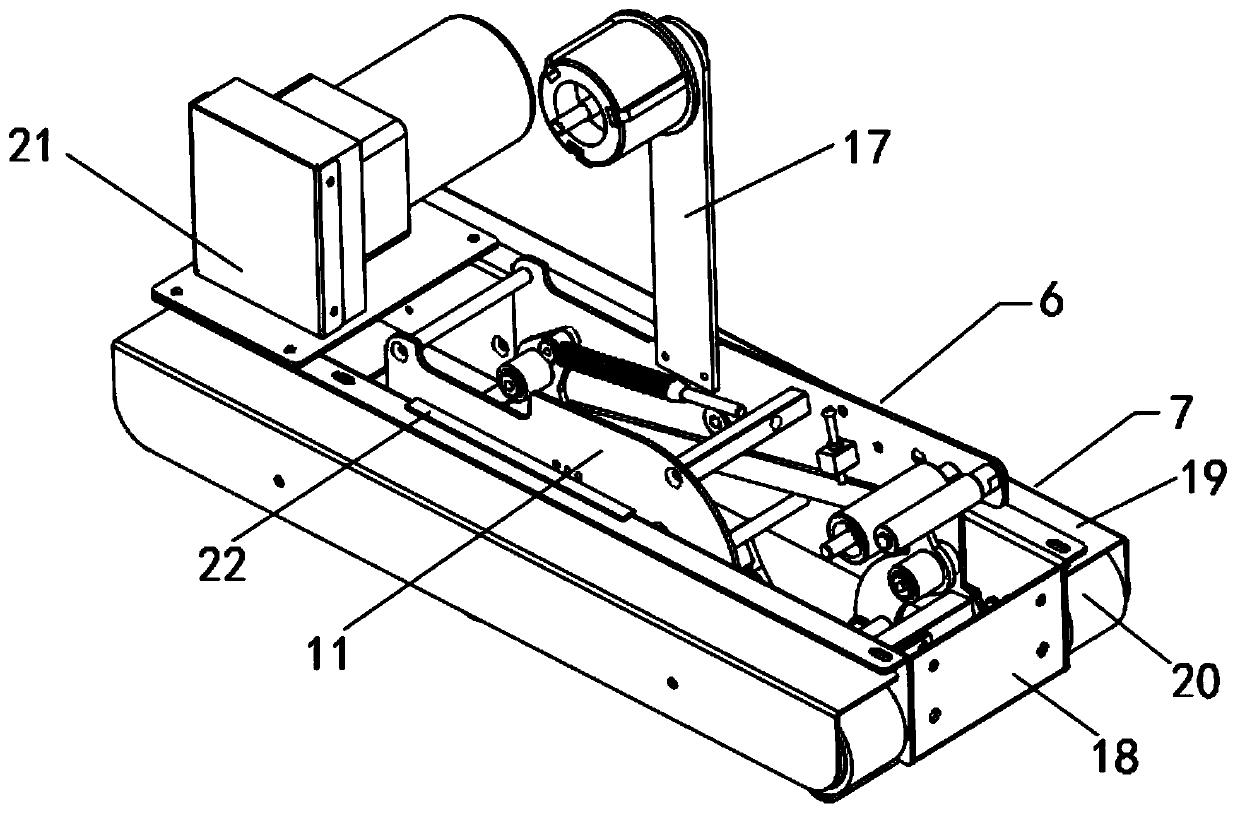

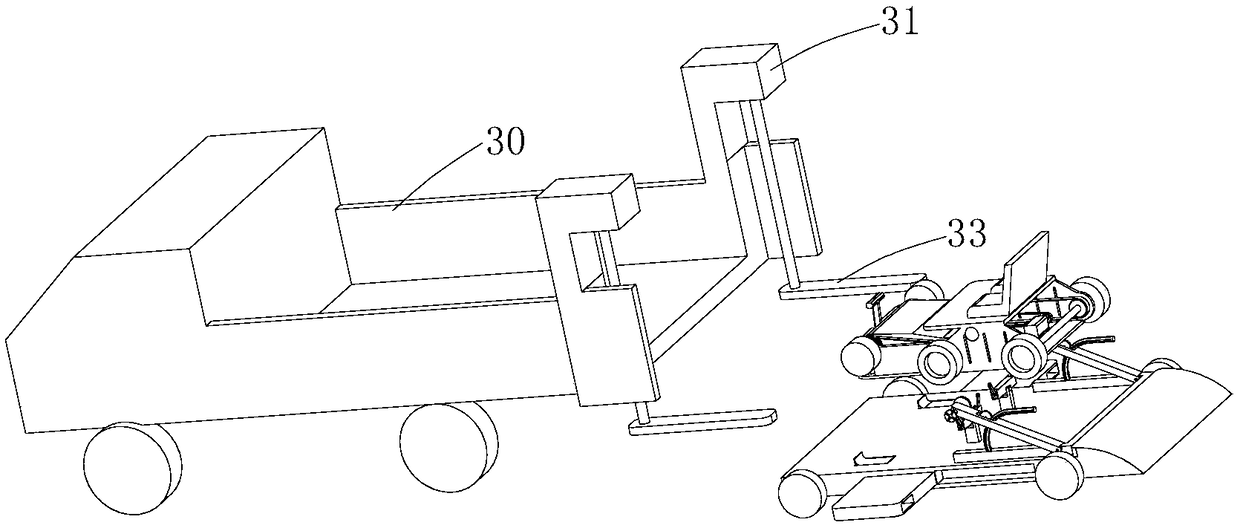

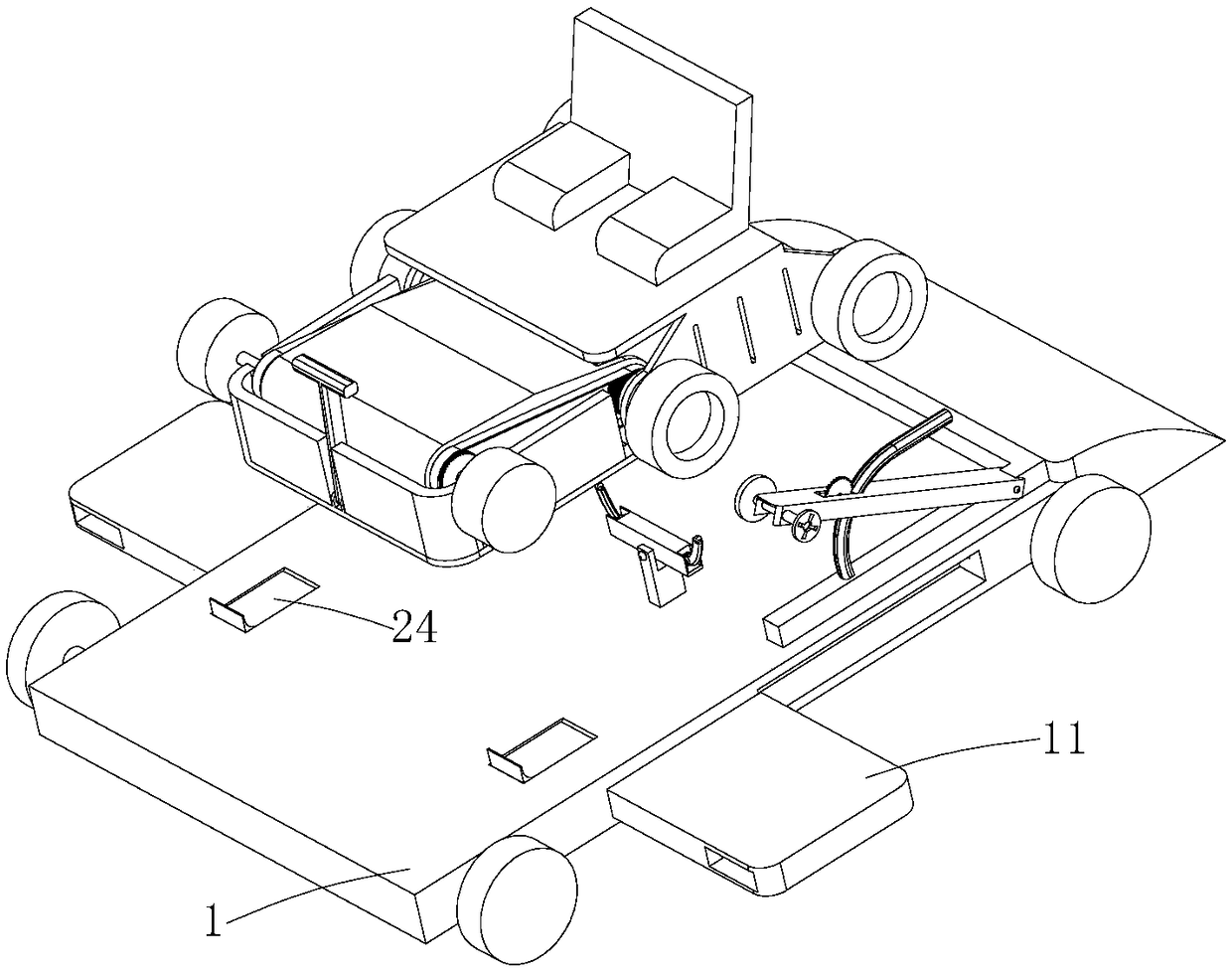

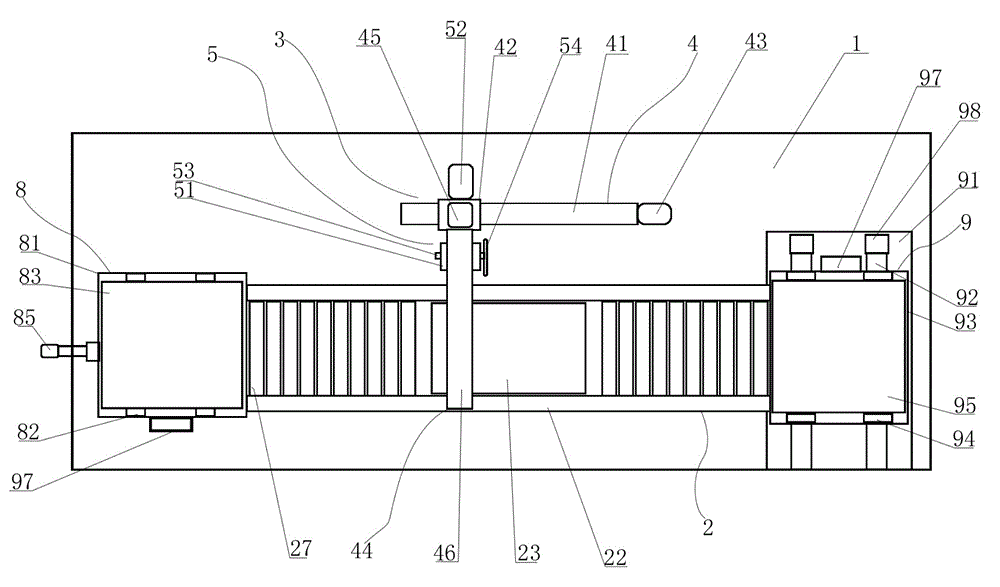

Braided fabric bagged crude tobacco packer carrying wire rope robot system

ActiveCN107127742AAvoid damageEliminate manual handlingProgramme-controlled manipulatorStacking articlesRobotic systemsGabion

The invention relates to a braided fabric bagged crude tobacco packer carrying wire rope robot system. The system is mainly used for tobacco re-drying enterprises and used for unloading braided fabric bagged crude tobacco packers, so that subsequent procedures are facilitated. The wire rope robot system is composed of at heat two wire rope robots and a transition conveying device. The first wire rope robot comprises a travelling device, a first wire rope robot rack, a first visual system device and a first extension and retraction system. The second wire rope robot comprises a travelling device, a second wire rope robot rack, a second visual system device and a second extension and retraction system. The transition conveying device and an artificial platform are mounted between the first wire rope robot rack and the second wire rope robot rack. The artificial platform is arranged in the upper position between the two wire rope robot racks. Through the system, the effect of loading and unloading the braided fabric bagged crude tobacco packers into gabions can be achieved, and the effect of stacking the braided fabric bagged crude tobacco packers in a freight yard can also be achieved; and meanwhile, manual carry is omitted, the working efficiency is improved, the equipment floor area is reduced, and a method for reducing tobacco damage is quite necessary.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

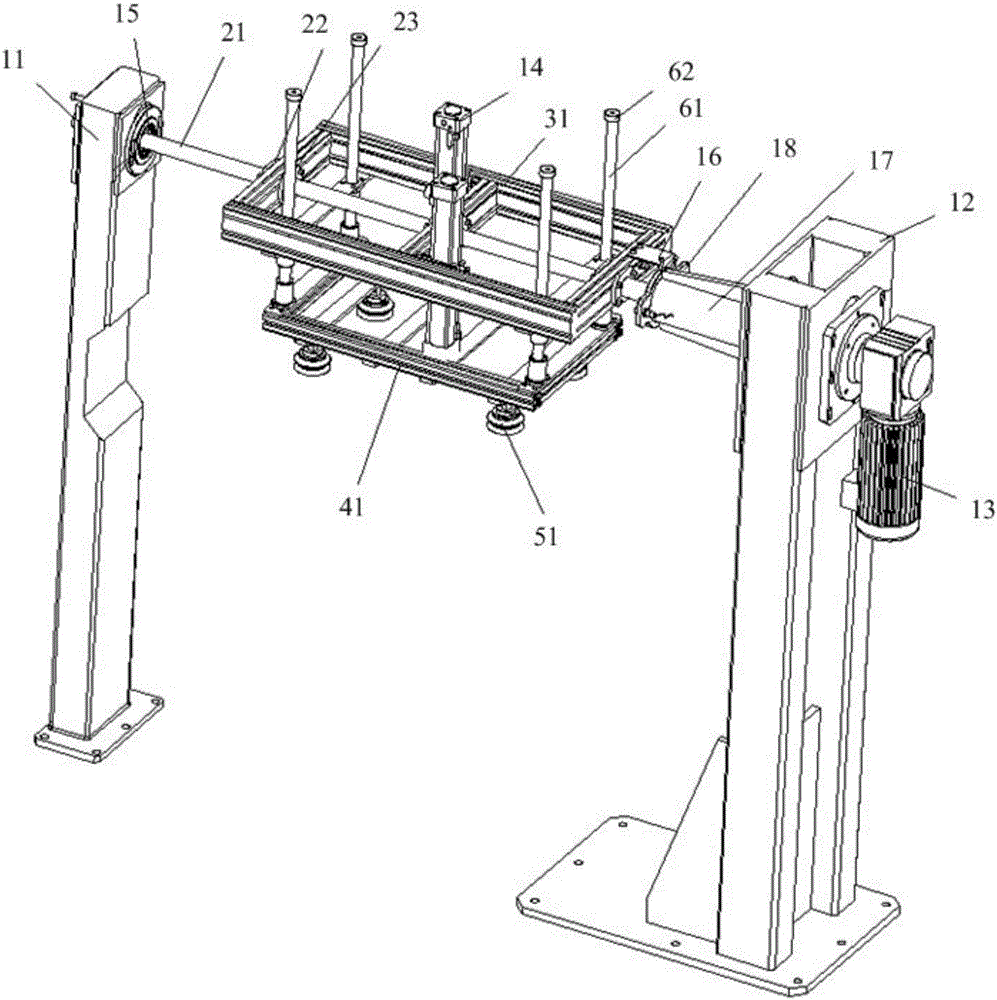

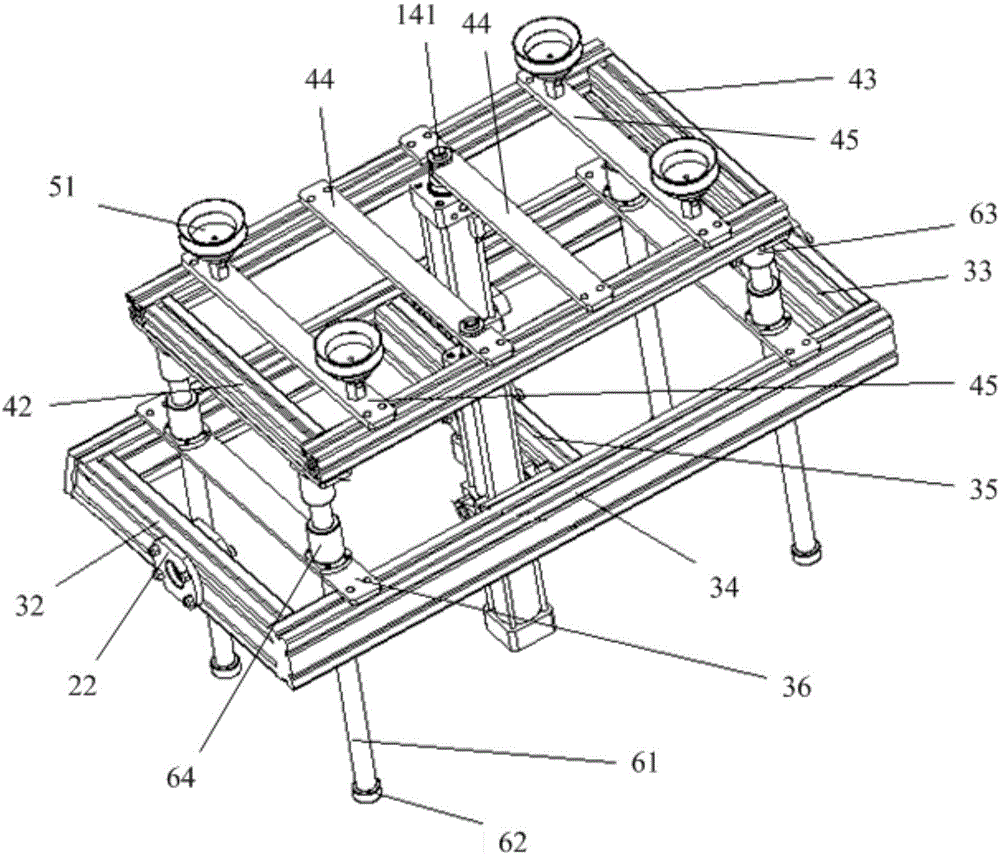

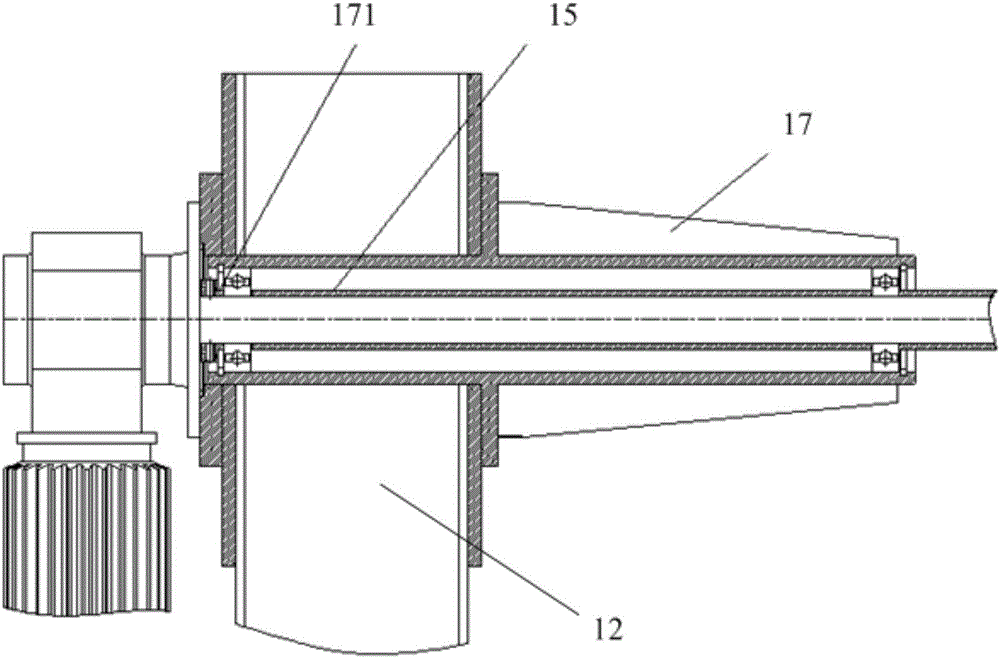

Windshield overturning mechanism

The invention provides a windshield overturning mechanism. The windshield overturning mechanism comprises a first supporting column and a second supporting column which are arranged opposite to each other, a rotary shaft, a driving piece for driving the rotary shaft to rotate, a flexible power piece, an overturning rack and a grabbing rack which is parallel to the overturning rack; the first end of the rotary shaft is rotatably connected to the first supporting column while the second end of the rotary shaft is rotatably connected to the second supporting column; the driving piece is arranged on the second supporting column, and the output end of the driving piece is connected to the second end; the overturning rack is arranged on the rotary shaft, the flexible power piece is arranged on the overturning rack, the flexible end of the flexible power piece is connected to the grabbing rack, and a sucking disc attracted to the windshield is arranged on the grabbing rack. According to the windshield overturning mechanism provided by the invention, manual carrying and overturning operations of an operator on the windshield are cancelled better, so that the labor intensity of the operator is greatly reduced, and the production efficiency is increased.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

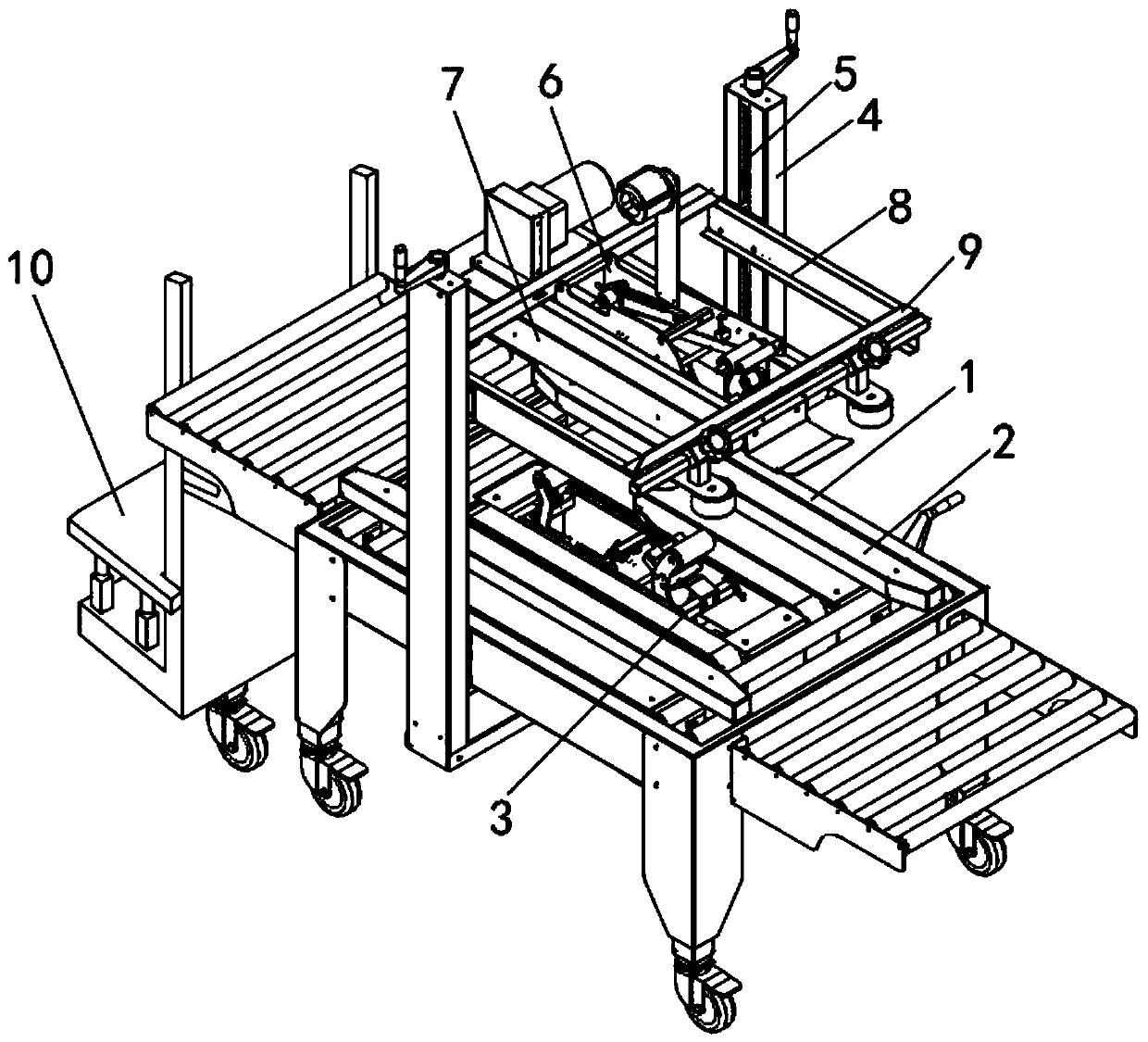

Device and method for sealing packaging boxes of small office equipment

PendingCN110395452AEliminate manual handlingLabor-saving operationWrapper twisting/gatheringMechanical engineeringEngineering

The invention discloses a device for sealing packaging boxes of small office equipment. The device for sealing the packaging boxes of the small office equipment comprises a conveying table. A centering assembly is installed at the top end of the conveying table, and a lower sealing assembly is arranged on the inner side of the top end of the conveying table. Lifting rods are connected to the frontend and the rear end of the conveying table correspondingly, and spiral rollers are arranged on the inner sides of the lifting rods. A fixing shell is connected tothe side walls of the exteriors of the spiral rollers in a manner of penetrating through the lifting rods. An upper sealing assembly is connected to the bottom of the fixing shell. A fastening frame is connected to the exterior of the upper sealing assembly and the exterior of the lower sealing assembly correspondingly. According to the device for sealing the packaging boxes of the small office equipment, the centering assembly andan auxiliary part are arranged in a cooperative manner, the circumstance that deviation occurs can be avoided when the packaging boxes are sealed, and the accuracy rate of sealing is improved; the upper sealing assembly and the lower sealing assembly are fixed by adopting clamping plates and connection rods and fastened through the fixing shell; a guide roller is convenient to clean; and a load transferring assembly is arranged, packaging boxes with sealing finished are convenient to transfer, and the trouble of manual carrying is omitted.

Owner:马鞍山观点信息科技股份有限公司

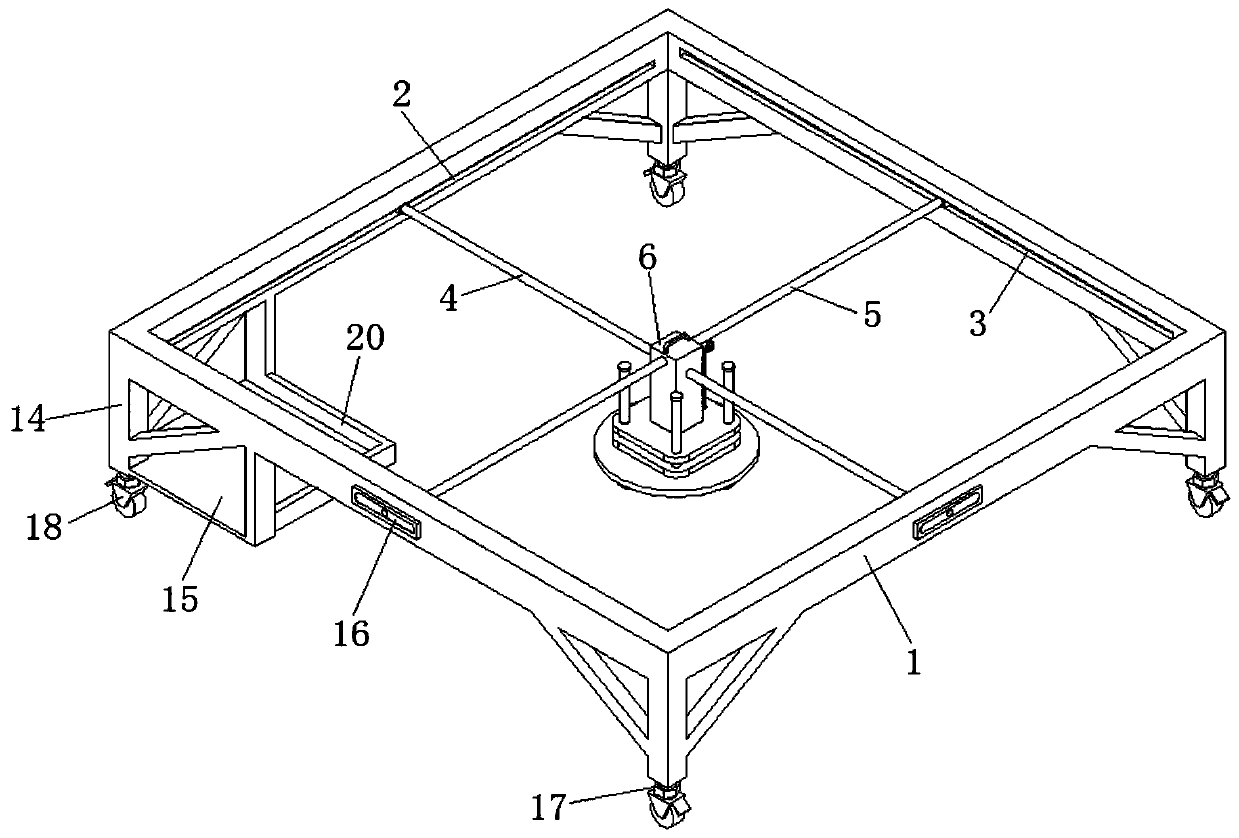

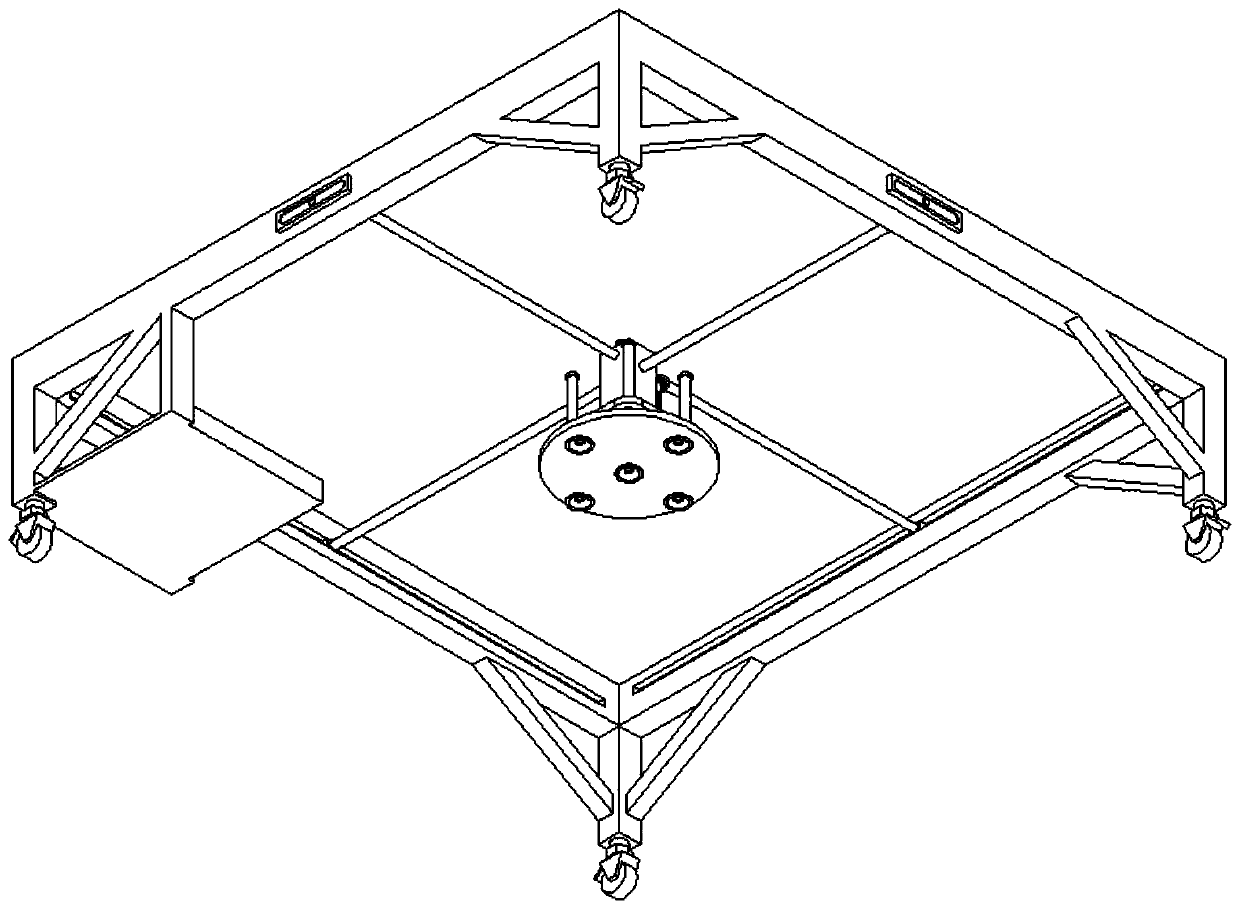

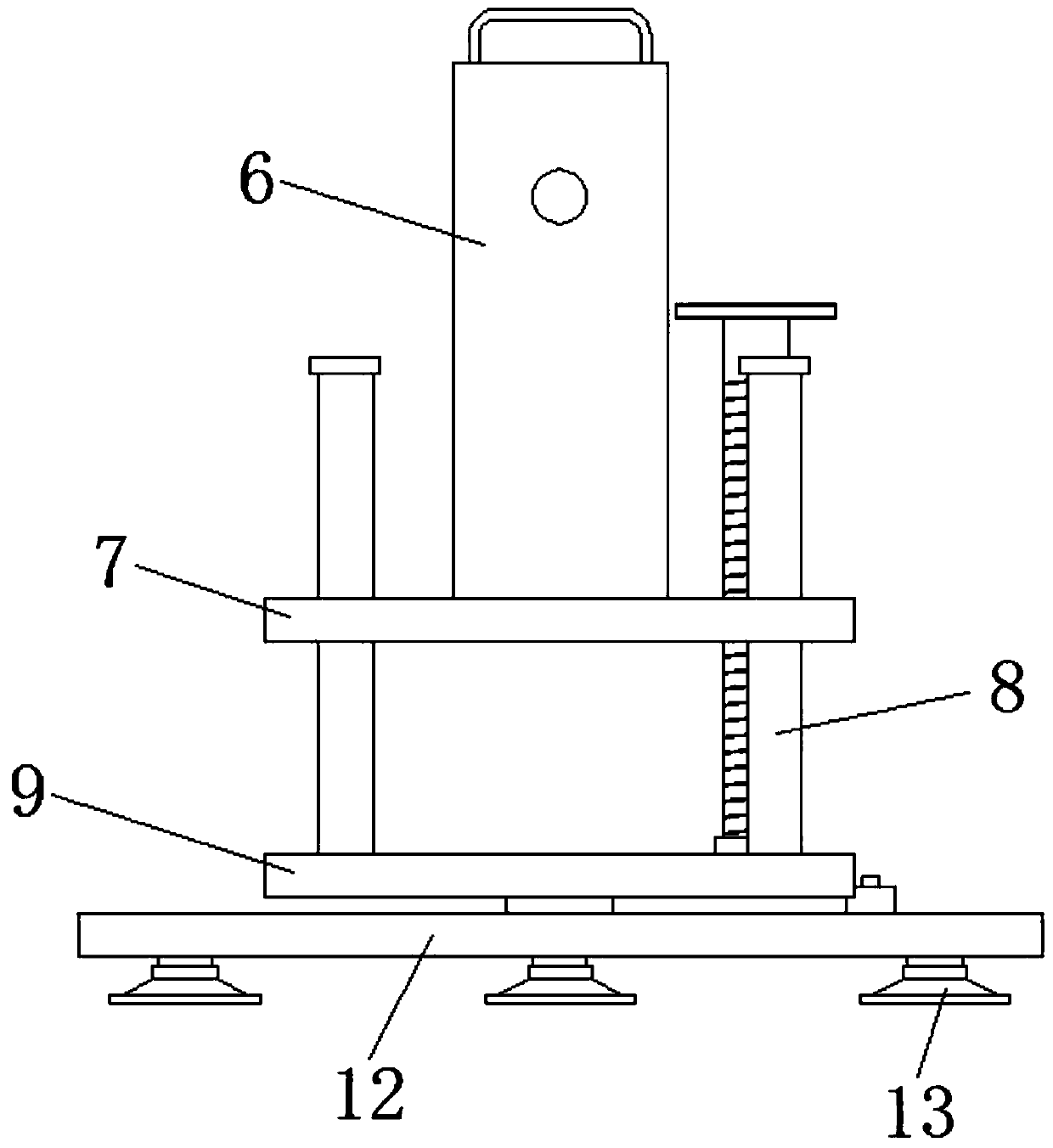

A transporter for a substation patrol inspection robot

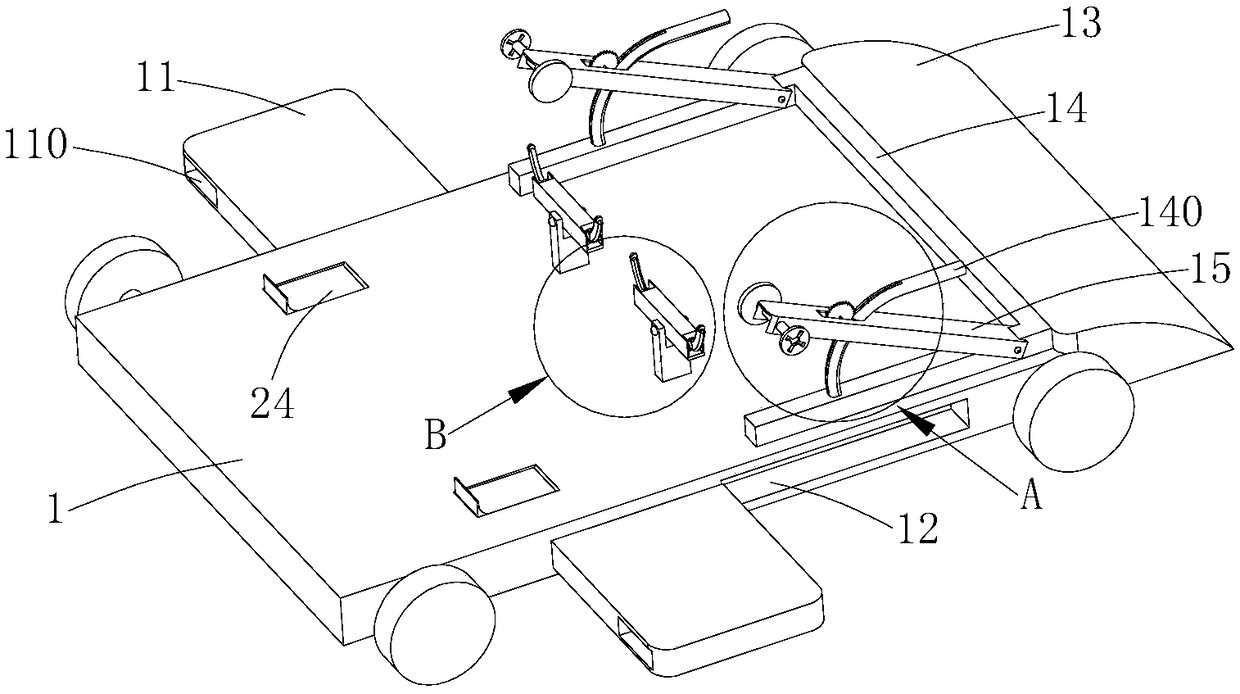

ActiveCN109204108AEasy to transportEliminate manual handlingVehicle manoeuvring devicesItem transportation vehiclesLateral positioningEngineering

The invention discloses a transporter for a substation patrol inspection robot in the field of a substation transport tool. The transporter comprises a pallet, a bottom plate, a mobile device and a driving device. The moving device comprises a bearing plate and a lateral positioning mechanism; The lateral positioning mechanism comprises a bottom positioning frame fixed with a bearing plate, an adjusting lever fixedly arranged above the bottom positioning frame and a rotating lever hinged with the bottom positioning frame, wherein the rotating lever is provided with a through groove through which the adjusting lever passes; the lateral positioning mechanism also comprises a contact piece, a threaded column and a rotating handle which are in close contact with the body part of the substationpatrol inspection robot; one end of the rotating rod facing away from the bottom positioning frame is provided with a threaded hole which is adapted to be pierced by the threaded column; one end of the threaded column is fixed with the contact piece, and the other end is fixed with the rotating handle. The transporter can fix the unbalanced patrol inspection robot and prevent the patrol inspection robot from component damage due to vibration during transportation.

Owner:鑫瑞璟教育科技(杭州)有限公司

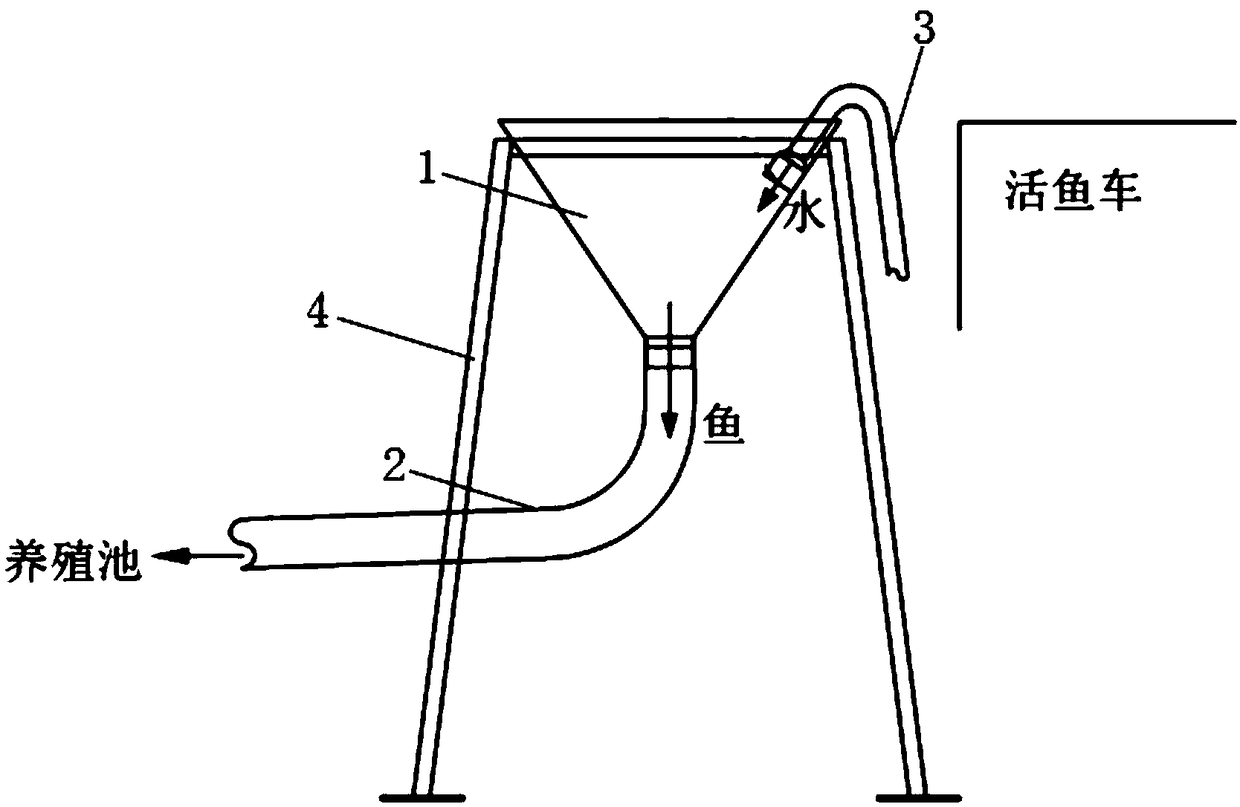

Method for unloading fry into pond

InactiveCN109479768AShorten pool timeStrong coherenceClimate change adaptationPisciculture and aquariaWater dischargeWater quality

The invention provides a method for unloading fry into a pond. The method includes the following steps that 1, after a live fish transport vehicle arrives at the scene, the water temperature and dissolved oxygen concentration of one fish tank is measured, the state of the fry is observed, and unloading work starts; 2, water is extracted from an aquaculture pond into the fish tank, until water in the fish tank is completely changed by water in the aquaculture pond; 3, a drainage valve at the bottom of the fish tank is switched on, and 1 / 3 of the water is discharged; 4, fry conveying equipment is assembled and placed near the live fish transport vehicle; 5, a submersible pump is turned on, water is injected into a conical container, a hand-held fishing net is used for catching the fry and putting the fry in the conical container, and the fry then enters a fish pipe with the water flow and finally reaches the aquaculture pond; 6, with fry catching, water discharge continues until all fryare caught; 7, when the fish tank is unloaded, the water quality of the fish tank is determined and water is changed, and unloading work of all the fish tanks is completed in turn. The method adopts uninterrupted pipeline transportation, each link has strong coherence, and the time of unloading fry into the pond can be shortened.

Owner:上海耕海渔业有限公司 +1

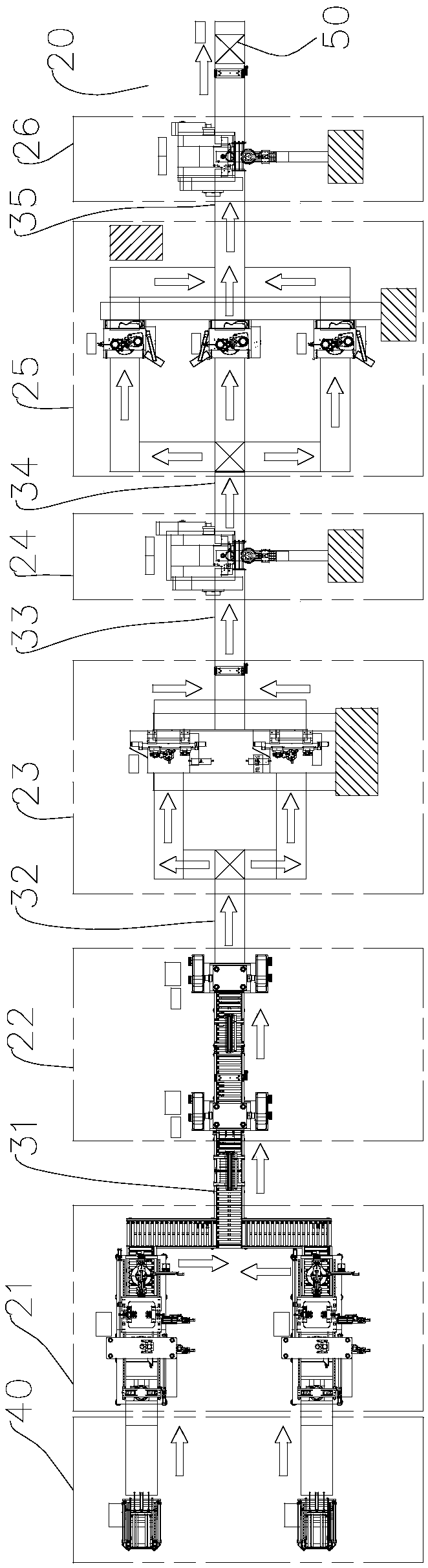

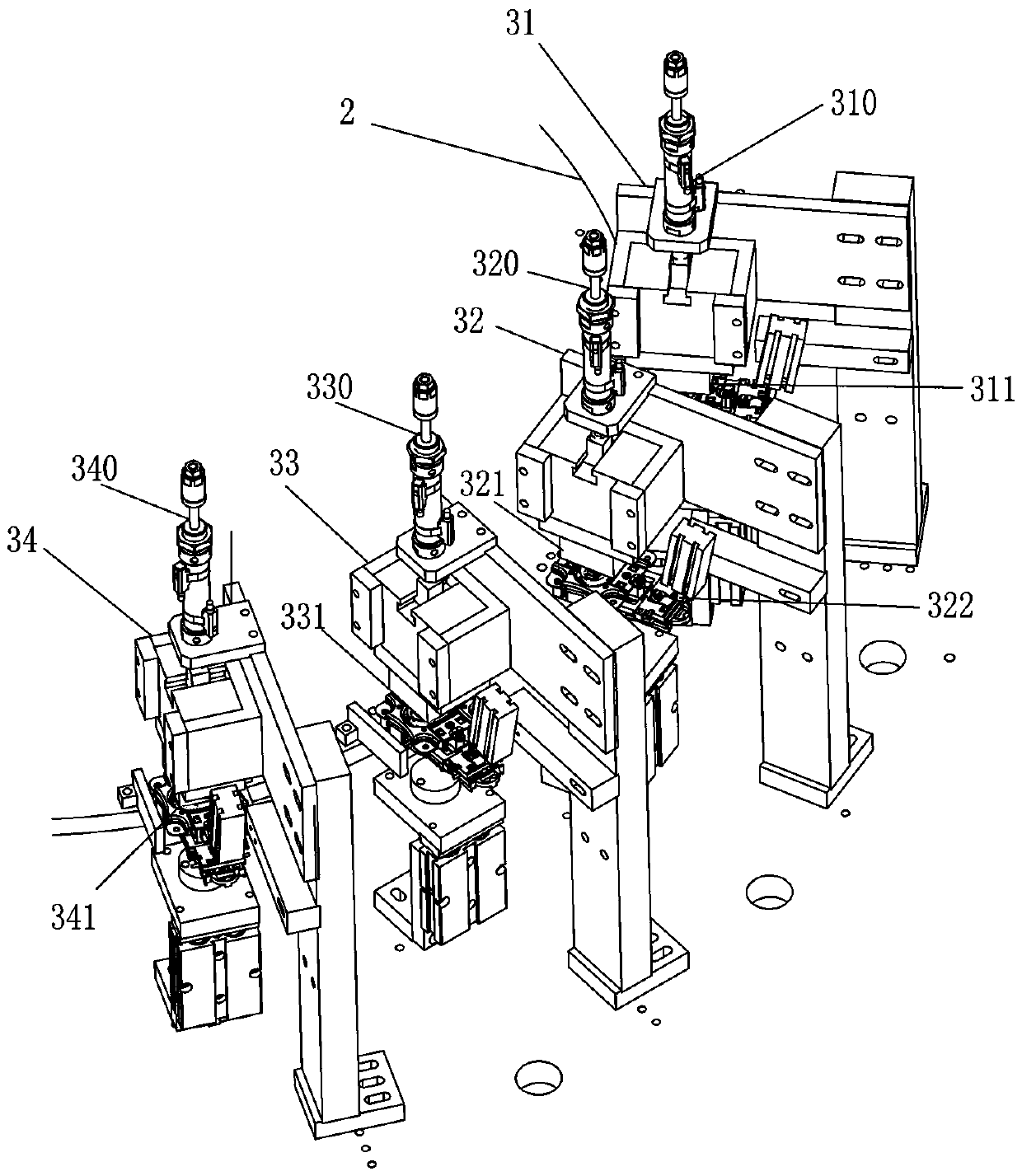

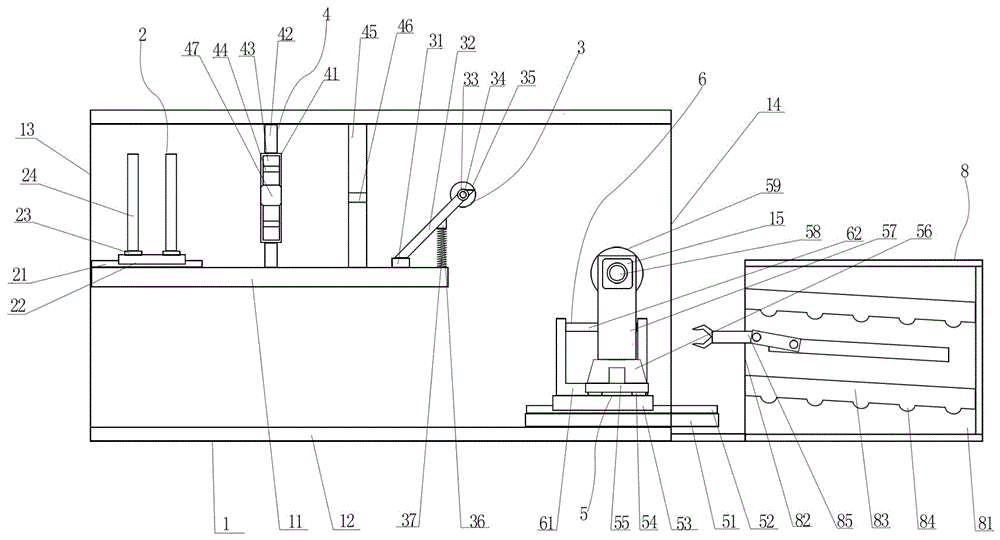

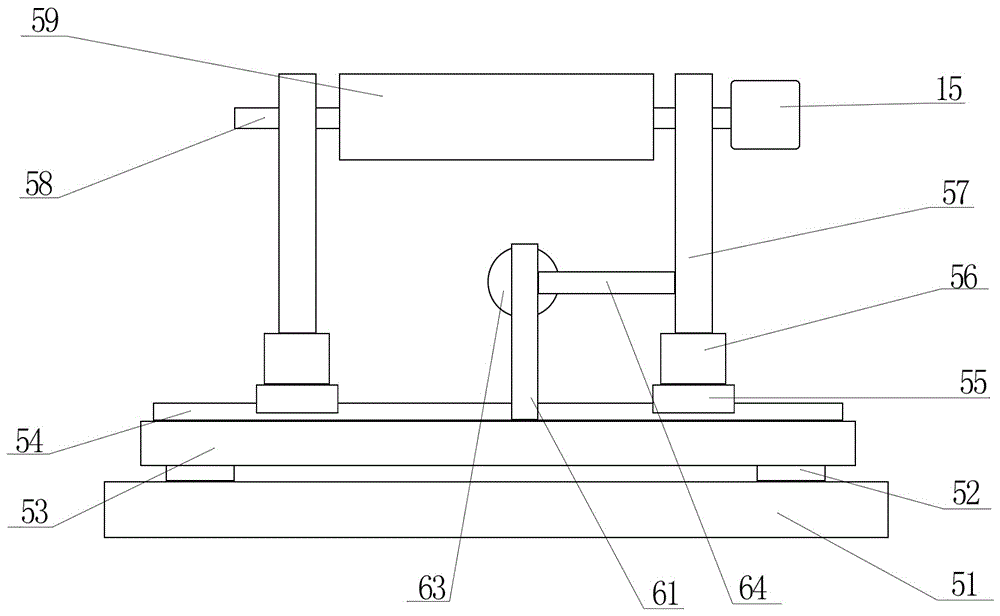

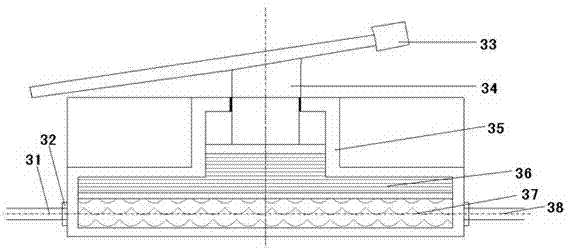

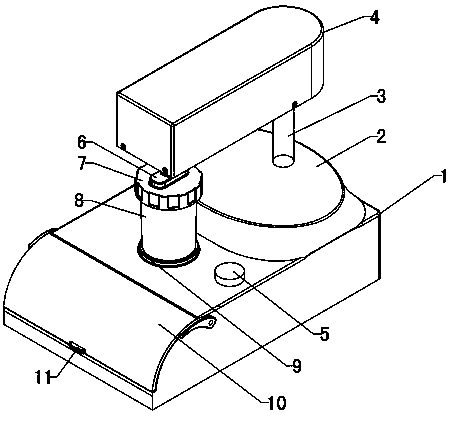

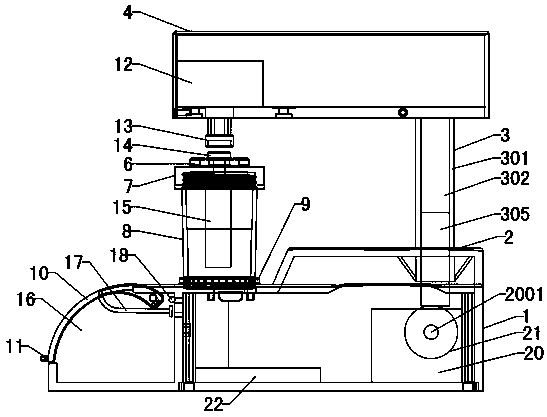

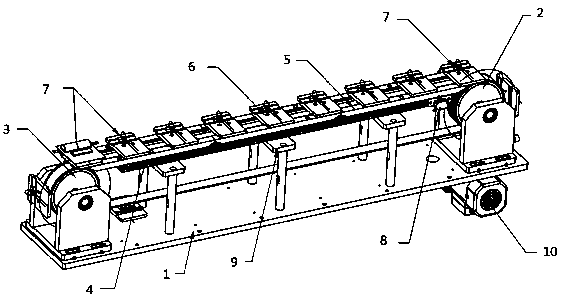

Detector for temperature sensitive controllers

ActiveCN109855895AEasy to controlEliminate manual handlingStructural/machines measurementConveyor partsControl engineeringSingle station

The invention relates to a detector for temperature sensitive controllers. The detector includes a control center and a multi-station operation rotary table; the control center is provided with a control panel; the multi-station operation rotary table is mounted above a rack and can rotate horizontally relative to the rack; the upper surface of the operation rotary table is provided with positioning and clamping devices; the quantity of the positioning and clamping devices is corresponding to the quantity of working stations; the positioning and clamping devices are used for supporting temperature sensitive controllers under test; and a thermal detection system is provided with a preheating station, a low-temperature detecting station and a high-temperature detecting station which are located on the multi-station operation rotary table. Compared with existing manual division detection, the detector can realize multi-station simultaneous detection from automatic feeding, part detection, result judgment to automatic unloading; the detection time of the detector depends on the longest detection time of a single station; and linked detection can be performed on a plurality of temperature sensitive controllers, and therefore, high efficiency and a high automation degree can be realized, and manpower and production costs can be greatly saved.

Owner:ZHEJIANG JIATAI ELECTRICAL APPLIANCE

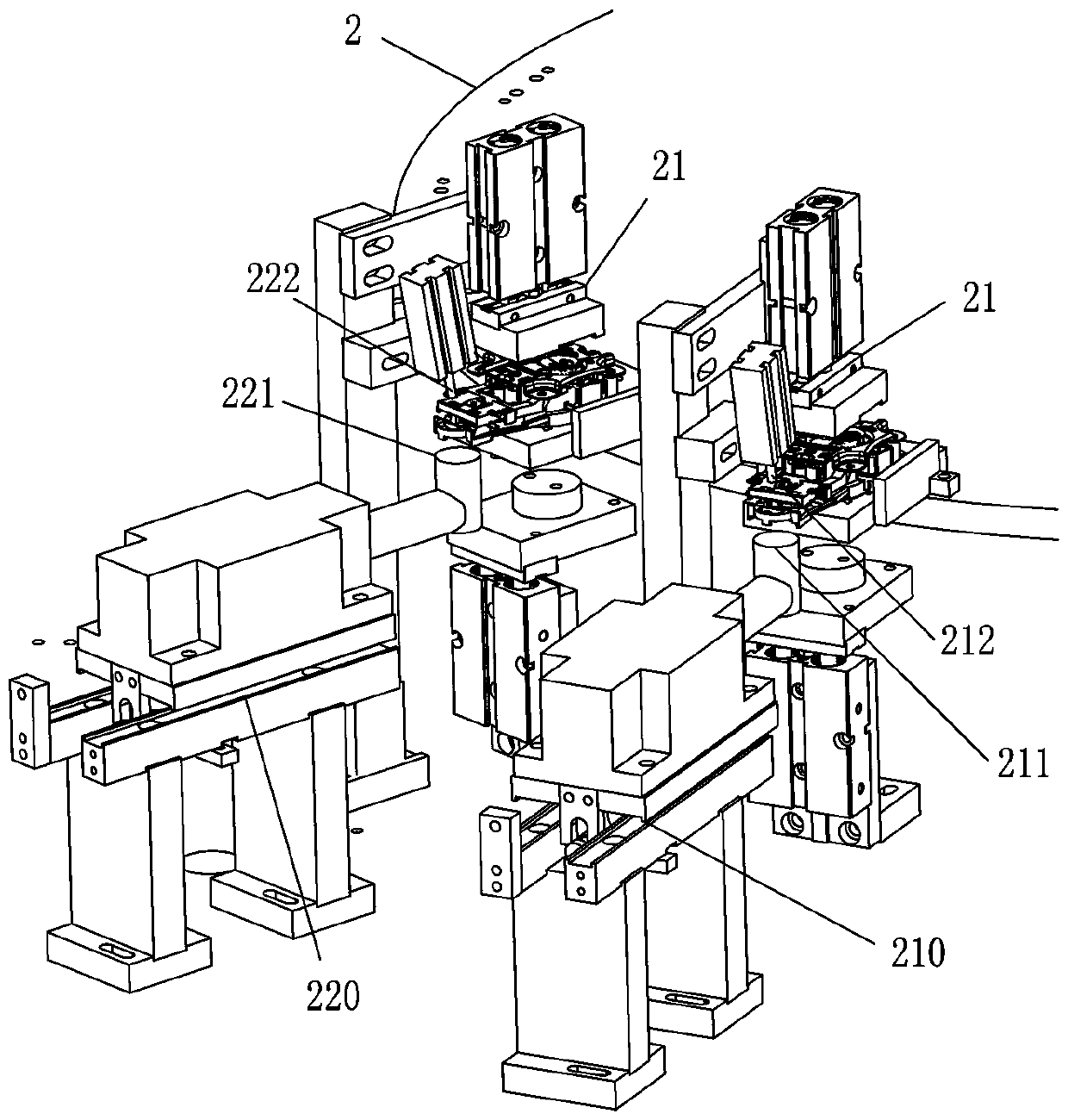

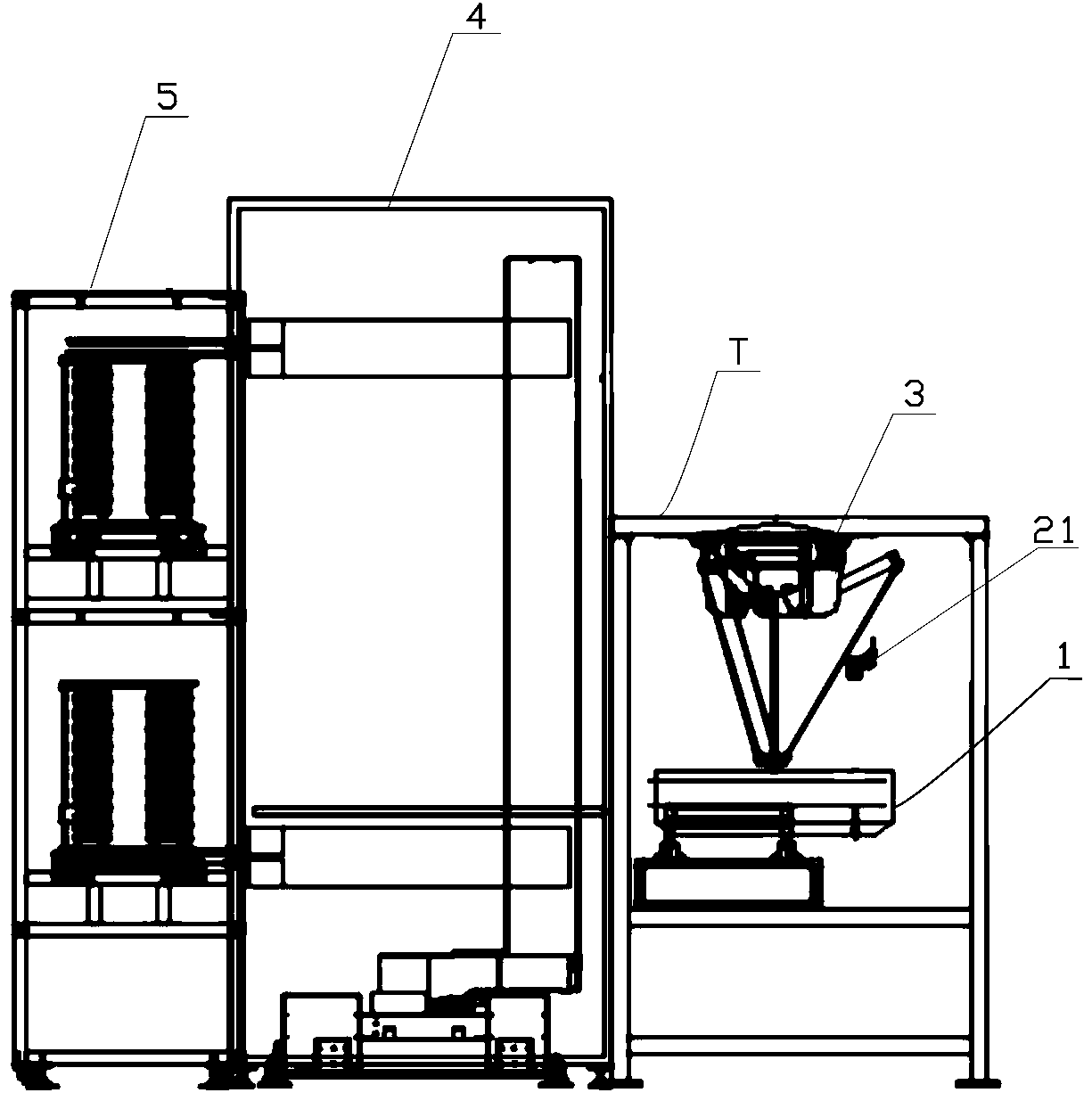

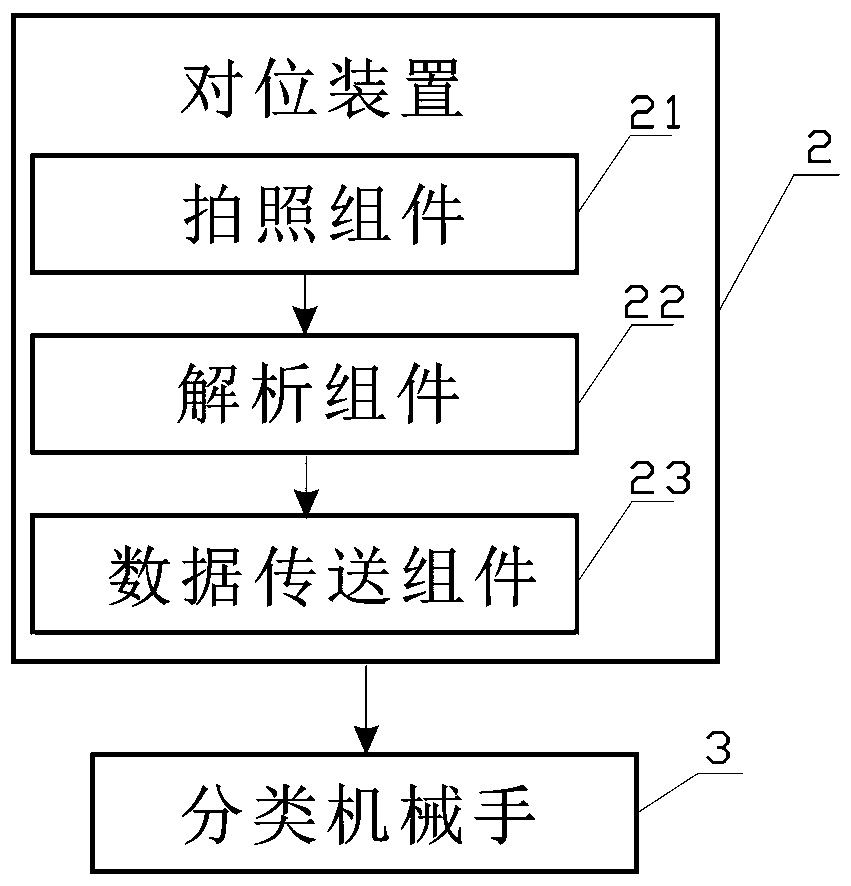

Panel sorting and shifting device

The invention discloses a panel sorting and shifting device. The panel sorting and shifting device comprises a grade buffer rack, an aligning device and a sorting mechanical arm, wherein the grade buffer rack adopts a multilayer structure; different specifications and grades of panels are laid on each layer of a grade buffer rack in positions according to the sequence of the panels; the aligning device is used for obtaining the positional deviation of the panels on a panel moving production line; the mechanical arm corrects of the positions of the panels according to data of the positional deviation of the panels, which is obtained by the aligning device, and lays the panels corresponding layers of the grade buffer rack, which matched with the specifications and degrades of the panels according to the specifications and degrades of the panels and laying positions corresponding to the sequences. Through the implementation of the panel sorting and shifting device, the panels can be rapidly grabbed and can be automatically sorted according to grades of products, the automatic handling efficiency and the yield of products are improved, the cost is further reduced, and the mounting space is saved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Doubling device

The invention discloses a doubling device which comprises a rack. A partition plate is horizontally arranged at the middle portion of the rack. The bottom of the rack comprises a bottom plate. One end of the partition plate is provided with a yarn unreeling assembly, and the other end of the partition plate is provided with a tightening assembly. A yarn stranding assembly is arranged between the yarn unreeling assembly and the tightening assembly. A winding assembly is arranged on the bottom plate. An outlet is formed in the side, with the winding assembly, of the rack. The winding assembly comprises a supporting plate arranged on the bottom plate. The supporting plate extends out of the outer portion of the outlet. Two parallel guide rails are horizontally arranged on the top of the supporting plate. A moving plate is arranged on the guide rails. The top of the moving plate is provided with sliding rails. A transverse plate is arranged on the sliding rails. Supports are arranged on the two sides of the transverse plate. Vertical plates are arranged on the tops of the supports. A winding shaft is horizontally connected between the two vertical plates. A winding roller is arranged on the winding shaft. One end of the rack is provided with a reeling assembly used for collecting and storing finished stranded yarn, the efficiency is improved due to automatic storing, manual carrying is omitted, and labor resources are saved.

Owner:WUJIANG XIAOYU JET WEAVING

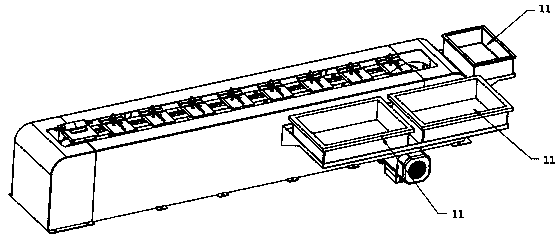

Electronic product assembly return line device

PendingCN111977302AReduce duplicate handlingIncrease profitConveyor partsMechanical conveyorsEngineeringMechanical engineering

The invention discloses an electronic product assembly return line device. The electronic product assembly return line device is used for circularly conveying a plurality of assembly platforms and comprises an upper line body, a lower line body arranged parallel to the upper line body and opposite to the upper line body in operation direction, and lifting mechanisms arranged at the two ends of theupper line body and the lower line body; the multiple assembly platforms are slidably arranged on the upper line body, the lower line body and the lifting mechanisms correspondingly; and the upper line body and the lower line body comprise driving mechanisms driving the assembly platforms to move between the upper line body and the lifting mechanisms or between the lower line body and the liftingmechanisms. According to the electronic product assembly return line device, the assembly platforms in the electronic product assembly process can be automatically returned, and manual repeated carrying is avoided.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

Heating ceramic tile mounting supporting device

InactiveCN110700537APrecisely adjust the laying positionQuick fit layingBuilding constructionsComposite materialCeramic tiles

The invention discloses a heating ceramic tile mounting supporting device, and relates to the technical field of heating ceramic tiles. The heating ceramic tile mounting supporting device comprises arectangular frame, wherein first sliding grooves are formed in one opposite inner walls of the rectangular frame, and second sliding grooves are formed in the other opposite inner walls of the rectangular frame; the surfaces of the first sliding grooves are connected with first sliding rods through sliding blocks, the surfaces of the second sliding grooves are connected with second sliding rods through sliding blocks, and the first sliding rods and the second sliding rods are arranged in an up-down staggered mode; and the surfaces of the first sliding rods and the surfaces of the second sliding rods are slidably connected with stand columns, through holes capable of being in sliding fit with the first sliding rods and the second sliding rods are formed in the surfaces of the stand columns,and fixing plates are fixed to the bottom ends of the stand columns. According to the heating ceramic tile mounting supporting device, a suction plate can adsorb heating ceramic tiles to move vertically and horizontally and rotate horizontally, the ceramic tile laying position can be accurately adjusted conveniently, the laying effect is good, meanwhile, the ceramic tiles can be quickly adsorbedand loosened for fitting laying, the ceramic tile laying difficulty is reduced, manual carrying of the ceramic tiles is omitted, the manual labor amount can be reduced, and the working efficiency is improved.

Owner:合肥品冠智能发热瓷砖有限公司

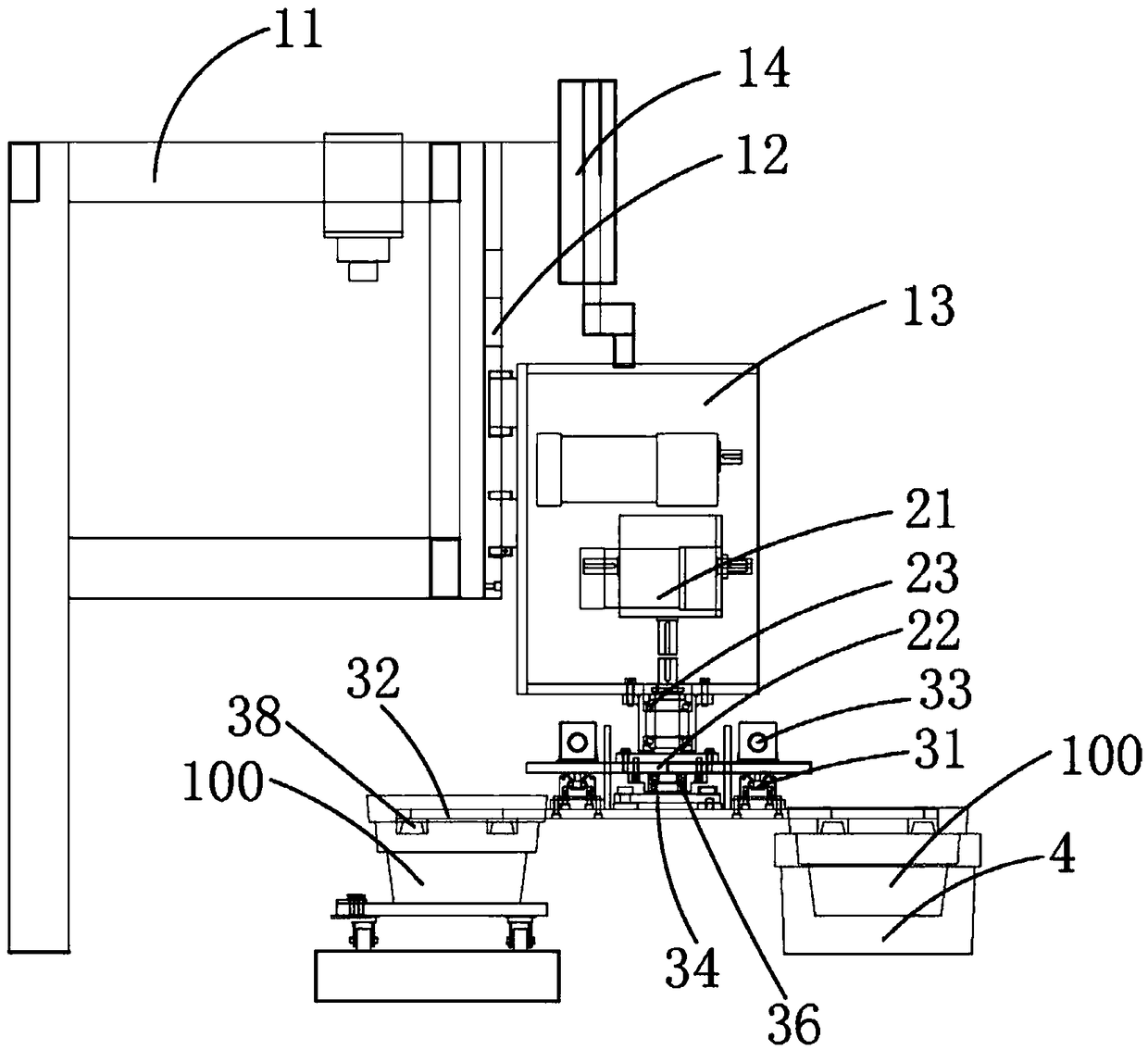

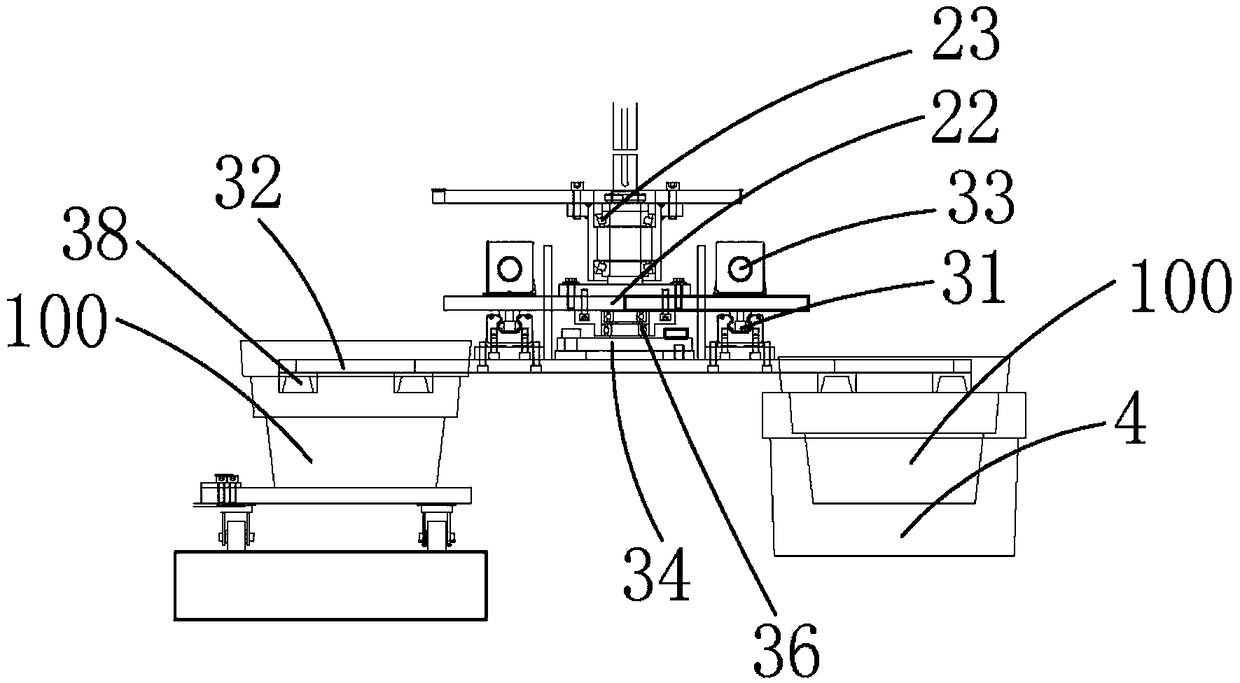

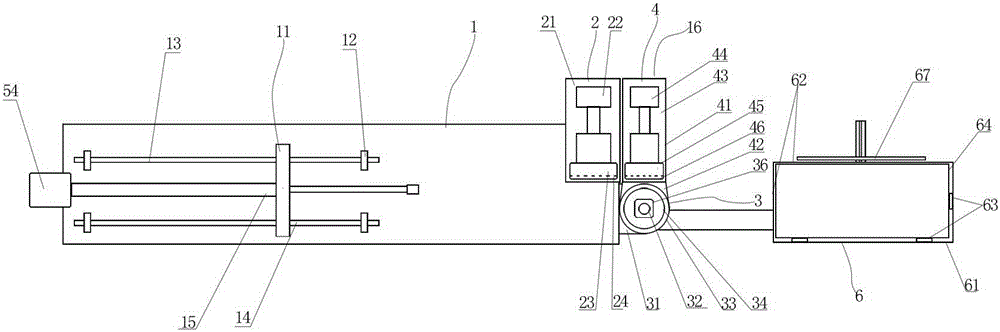

Hub oil seal press fitting production line

PendingCN114178825AAvoid damageRealize automatic operationMetal working apparatusProcess engineeringElectric control

The invention relates to the technical field of oil seal press fitting, in particular to a hub oil seal press fitting production line which comprises a press fitting machine for pressing an oil seal into a hub, manpower is saved, damage to the oil seal is reduced, a feeding mechanism and a discharging mechanism are arranged on the two sides of the press fitting machine respectively, and therefore the manual carrying link is omitted, and the production efficiency is improved. Automatic operation of the production line can be achieved through an electric control system, namely, the processes of feeding, press fitting and discharging are automatically completed, and semi-automatic production is achieved.

Owner:HUBEI TRI RING AXLE

Copper pipe bending machine with storage function

InactiveCN105234220AEasy to operateEasy to storeMetal-working feeding devicesPositioning devicesEngineeringPress brake

The invention discloses a copper pipe bending machine with a storage function. The copper pipe bending machine comprises a rack and is characterized in that a pushing device and a bending device arranged on one side of the pushing device are arranged on the rack; the bending device comprises a first bending part arranged on the right side of the top of the rack, a rotating part arranged on the right side surface of the rack and a second bending part connected with the rotating part; the first bending part and the second bending part are arranged in parallel; a copper pipe storage frame is arranged on one side of the bending device; the copper pipe storage frame comprises a bin body; openings are formed in two adjacent sides of the bin body; the opening in one side corresponds to the bending device; sliding rails are arranged on the inner sides of the bin body; box body is arranged on the sliding rails; a plurality of interlayers are arranged in the box body at equal intervals; the bottom of the bin body is connected with a telescopic device at the bottom of the box body; the two sides, corresponding to the bin body, of the box body are hollow; and a pushing plate used for pushing copper pipes is arranged on one side of the bin body.

Owner:苏州沃尔非自动化设备有限公司

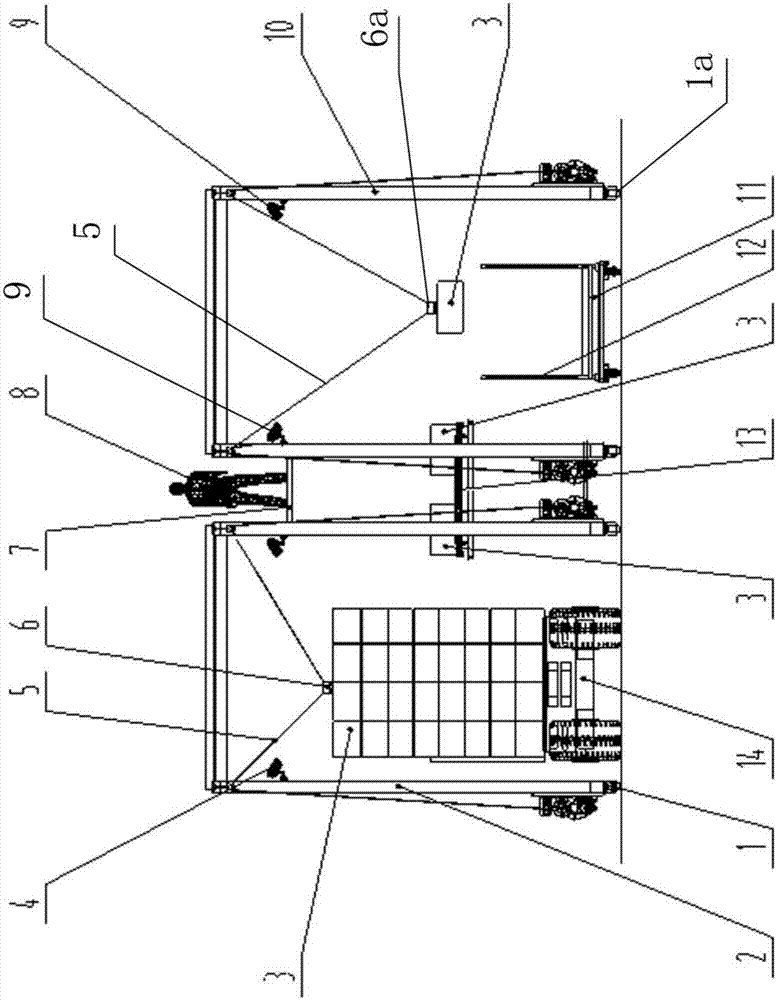

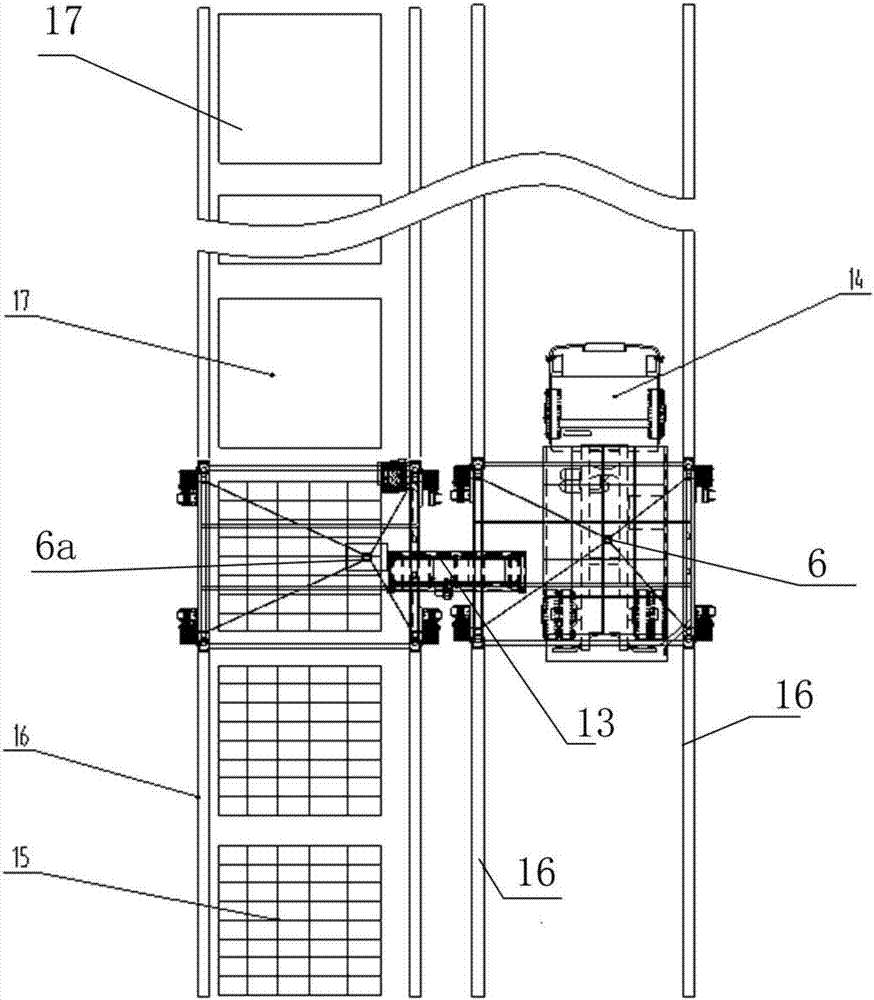

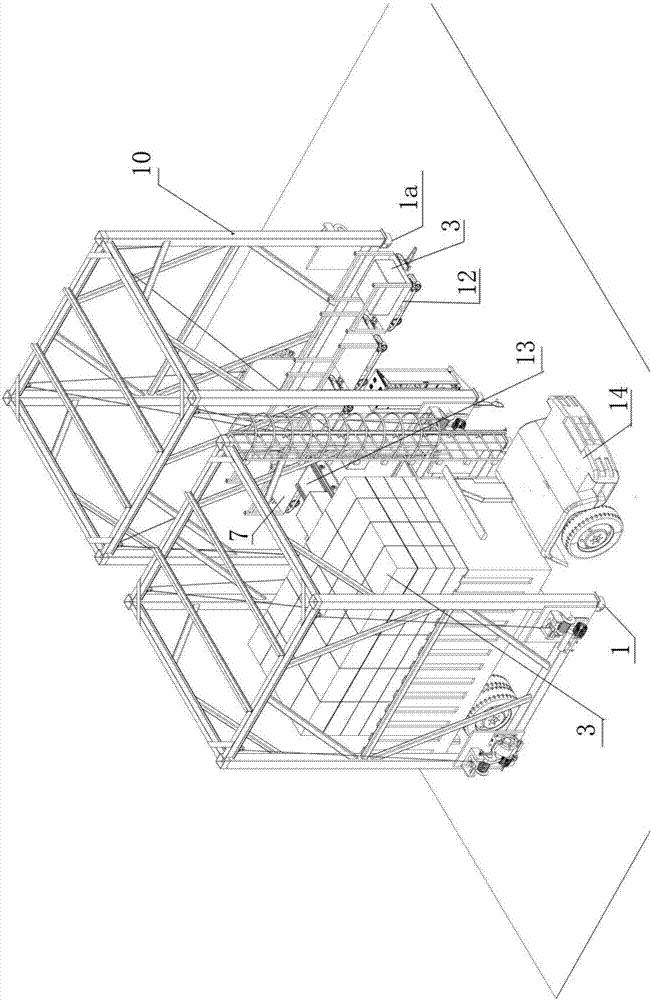

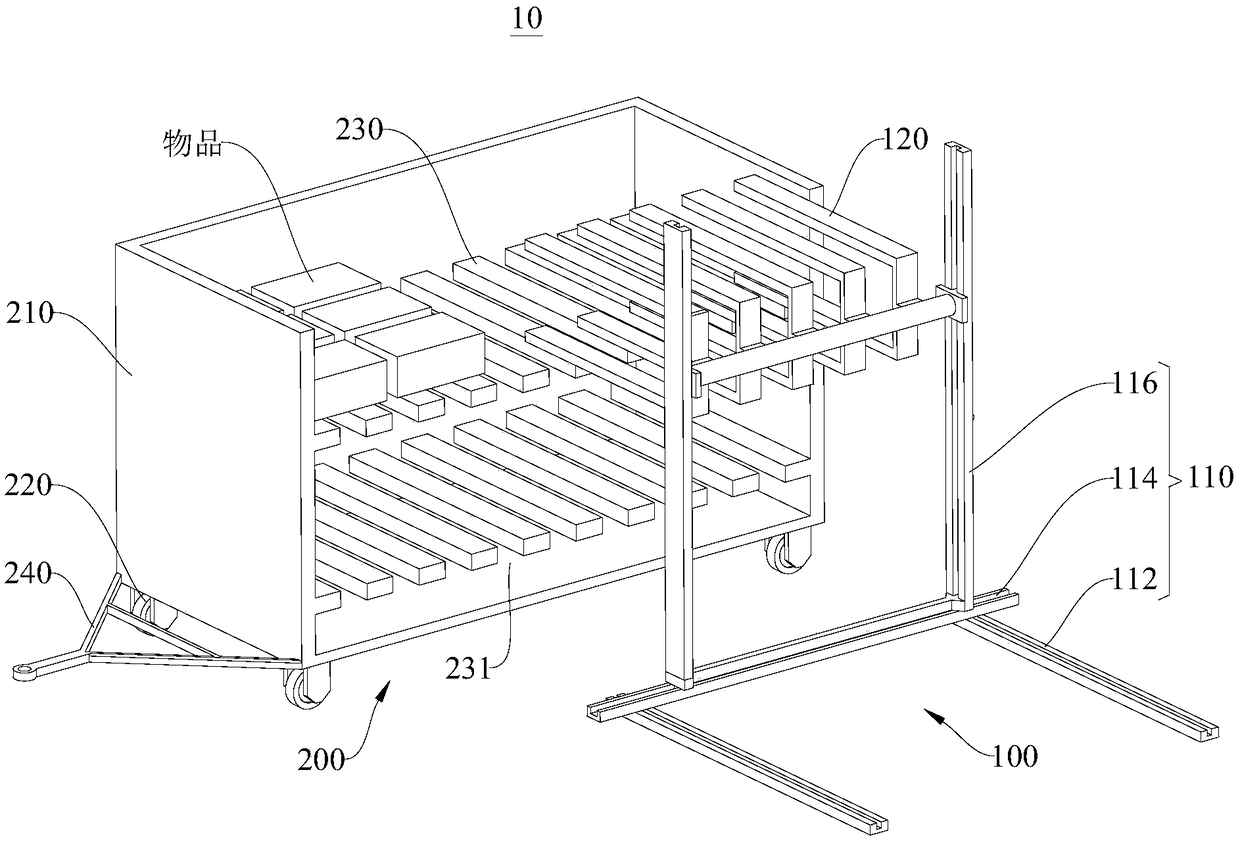

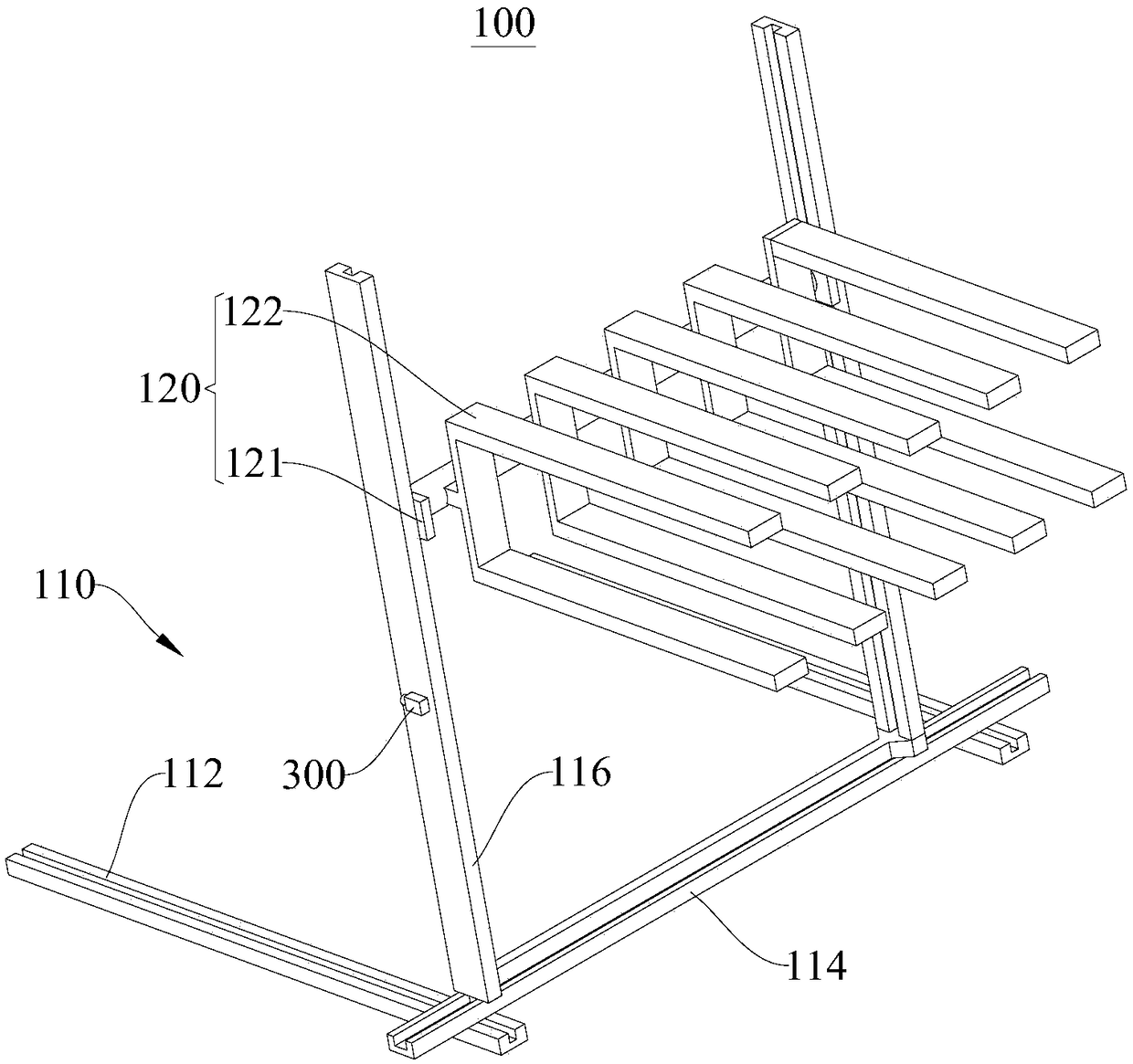

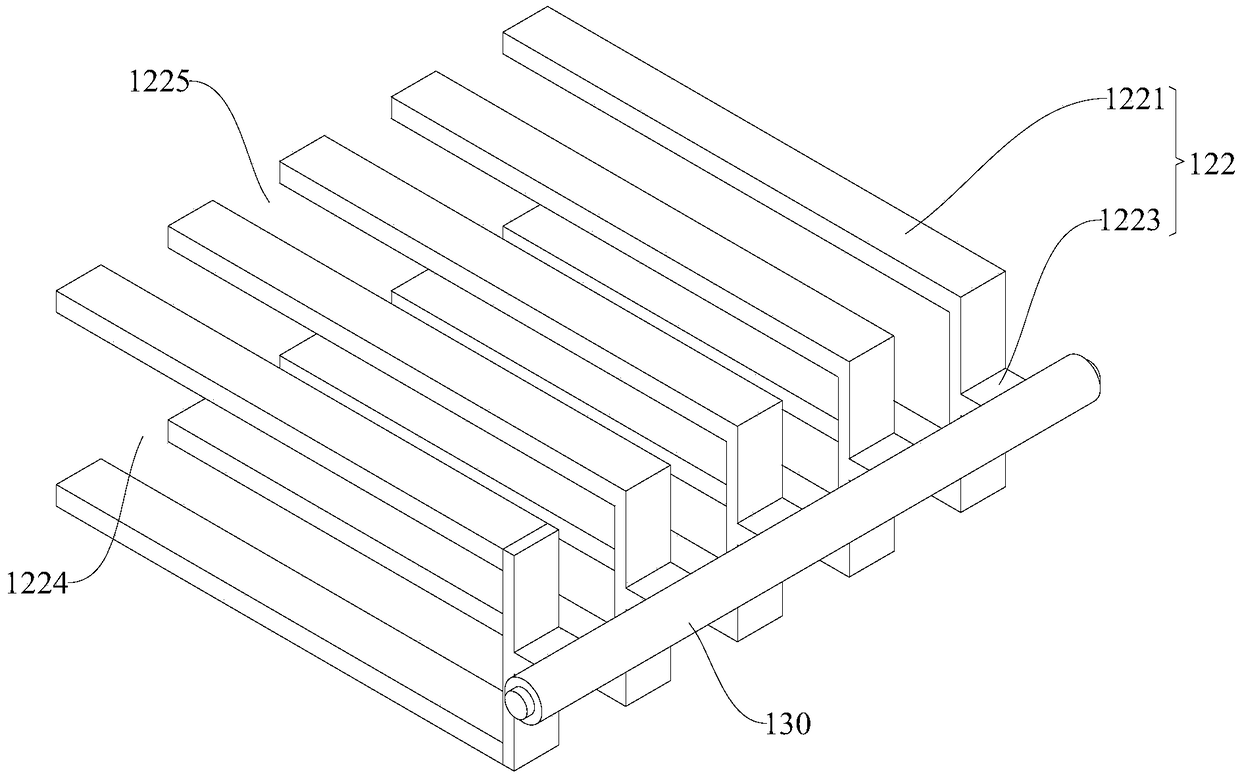

Handling device and system

PendingCN109398742ARealize automatic loading and unloadingGuaranteed integrityFreight handling installationsVehiclesEngineeringHandling system

The invention discloses a handling device and system, and relates to the technical field of baggage handling. The handling device includes a handling structure and a baggage cart. The baggage cart includes a cart body, wheels and a bearing layer, the wheels are arranged on the cart body and used for driving the cart body to move, and the bearing layer is arranged on the cart body. The handling structure includes a track assembly and an overturn assembly, the overturn assembly includes a driving device and an overturn finger, the overturn finger and the driving device are connected in a transmission mode, the driving device is used for driving the overturn finger to rotate, and arranged on the track assembly, and the track assembly is used for adjusting the positions of the driving device and the overturn finger. The bearing layer is provided with a plurality of clearances which are matched with the overturn finger, and thus the overturn finger can rotate in the clearances. The invention further provides the handling system including the handling device. According to the handling device and system, baggage can be automatically loaded and unloaded, and manual handling is avoided; andit is further ensured that the baggage is handled steadily and in a good condition.

Owner:SICHUAN UNIV

Positioning gluing device for gluing machine

InactiveCN112774925AEnsure safetyGuaranteed cleanlinessLiquid surface applicatorsCleaning using gasesElectric machineryDust control

The invention discloses a positioning gluing device for a gluing machine. The positioning gluing device comprises a main machine table, a conveying device is rotationally arranged below the main machine table, a first sliding groove is formed in the position, close to the front side edge and the rear side edge, of the upper face of the main machine table, a first sliding plate is arranged on the first sliding groove in a sliding mode, and a first sliding strip is integrally formed below the first sliding plate. A storage battery is fixedly arranged on the outer side wall of the rear face of the main machine table through a bolt. Second sliding grooves are formed in two sides of the first sliding plate. A second sliding plate is arranged on the second sliding grooves in a sliding manner, a sliding strip II is integrally formed below the second sliding plate, a heating device is fixedly arranged on one side of the upper face of the second sliding plate through a bolt, and a gluing device is fixedly arranged at the middle position of the second sliding plate. A secondary dust removal device is fixedly arranged on the other side of the second sliding plate through bolts, and a primary dust removal device is rotationally arranged on one side of the main machine table and located over a second motor. The positioning gluing device for the gluing machine has the beneficial effects that positioning can be achieved, gluing is even, glue leakage is avoided, and multi-structure combined work is achieved.

Owner:常州苏橡橡塑制品有限公司

Semi-automatic glass cutting machine

The invention discloses a semi-automatic glass cutting machine which comprises a rack and is characterized in that a bearing device is arranged on the rack, ones side of the bearing device is provided with a cutting device, the cutting device comprises a mechanical arm component arranged on the rack and a cutting component arranged on the mechanical arm component, one side of the bearing device is provided with a discharging cabin, the discharging cabin comprises a first hollow cabin body arranged on the rack, the two sides of the first cabin body are respectively provided with a third sliding rail, a first box body capable of moving up and down along the third sliding rails are arranged on the third sliding rails, and the first box body is horizontally provided with a plurality of first interlayers for placing glass; the rack is provided with a groove in the other side of bearing device, and a material receiving component is arranged in the groove; one side of the first cabin body and one side of a second cabin body are provided with driving devices which are respectively connected with the first box body and a second box body, and the driving devices can control the first box body and the second box body to move up or down.

Owner:苏州市灵通玻璃制品有限公司

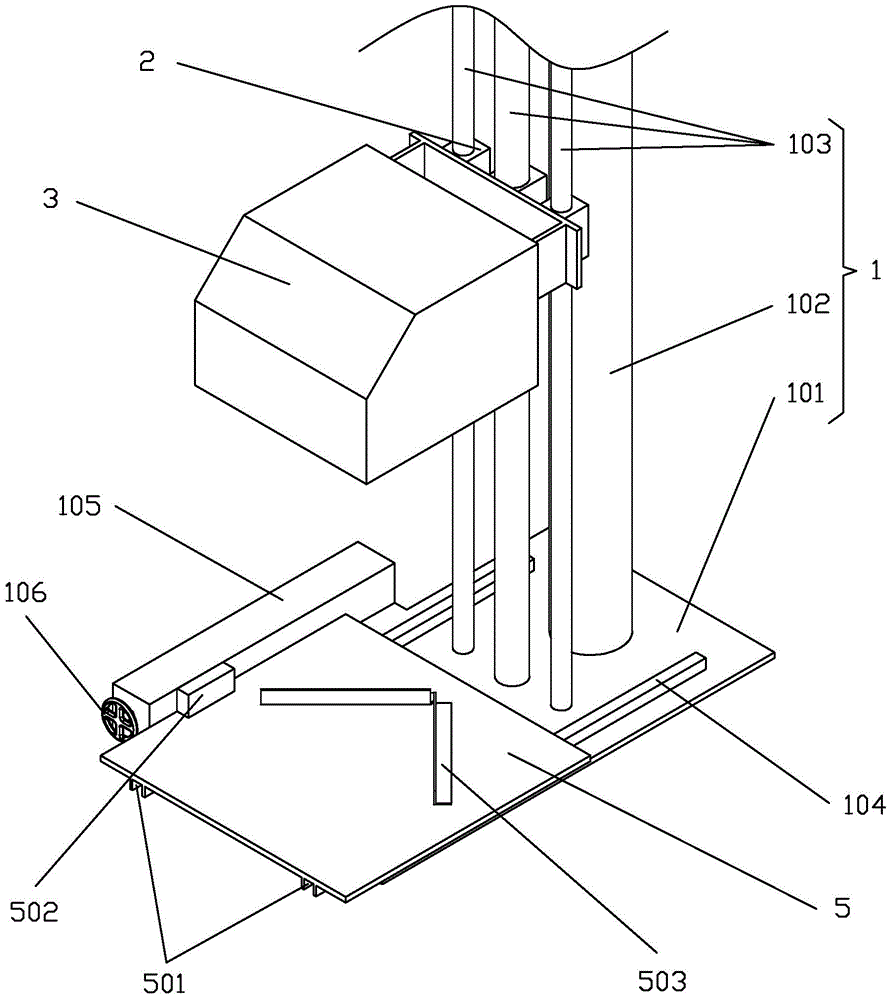

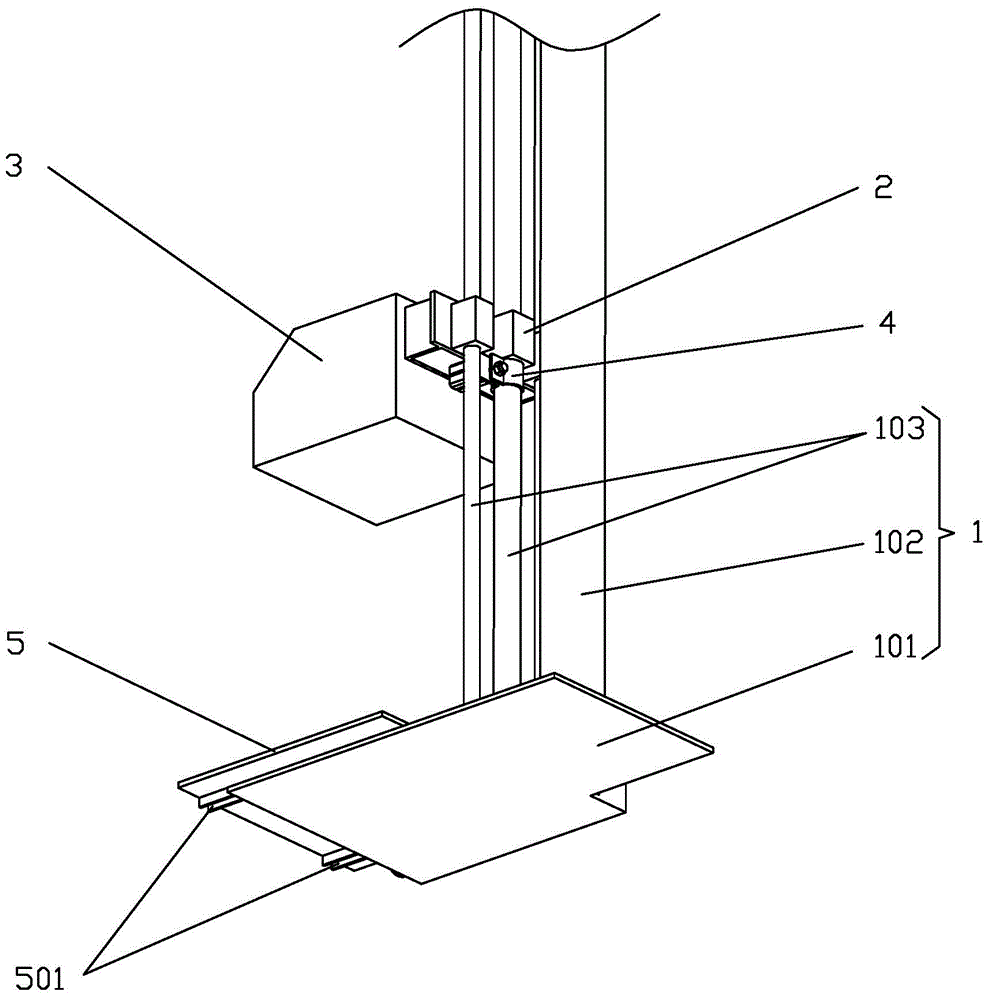

Efficient paint spraying equipment and process for plate processing

InactiveCN114308480ATo achieve the purpose of automatic paintingUniform paint jobLiquid spraying apparatusStructural engineeringIndustrial engineering

The efficient paint spraying equipment comprises a guide rail base, a guide rail baffle and guide rails are arranged at the upper end of the guide rail base, a paint spraying frame is arranged on the two guide rails, an operation panel is arranged on one side of the paint spraying frame, a liquid crystal screen, a power switch and setting buttons are arranged on the front side of the operation panel, and a conveying pipe is connected to the other side of the paint spraying frame. A pressurizing paint bucket and a rolling crawler belt are arranged below the conveying pipe, a paint spraying head is arranged below the inner side of the paint spraying frame, a supporting base, a supporting base sliding block and a supporting base guide rail device are arranged between the guide rail bases, and a supporting base guide rail baffle is arranged at the end of the supporting base guide rail device. Through the arrangement of the guide rail, the guide rail base, the pressurization paint bucket, the paint spraying head, the supporting base guide rail device, the plate limiting groove and the like, conventional paint spraying equipment can have the functions of automatic paint spraying, automatic feeding, plate limiting and fixing and the like.

Owner:唐秀兰

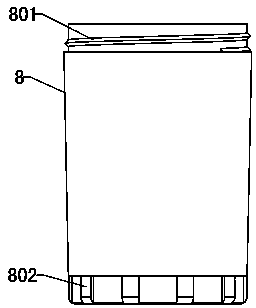

Portable muddy water purifier

InactiveCN104710049AZero emissionIncrease profitTreatment involving filtrationWater/sewage treatment by ion-exchangeFiltrationMolecular level

The invention relates to a portable muddy water purifier comprising a large solid granule treatment system, a one-way check valve, a machine shell, a rotating joint, a water flow pressurization system, a one-way check valve, a throttle valve, a macro filtration system, a pressure valve and a micro filtration system, wherein the large solid granule treatment system used for filtering large granular impurities in water is connected with the water flow pressurization system through the one-way check valve, the liquid pressure is increased by manual pressurization, the water flow pressurization system is connected with the macro filtration system through the one-way check valve for physical adsorption, and the macro filtration system is connected with the micro filtration system through the pressure valve for chemical sterilization and molecular level micro water purification. The equipment is small in volume, light in weight and is convenient to carry. Moreover, since the power source is manpower, the portable muddy water purifier has the advantages of zero emission, no pollution, simple operation and good firmness.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Intelligent winding machine

InactiveCN105480754AFast and efficient windingEliminate manual handlingWebs handlingWinding machineDrive wheel

The invention relates to an intelligent winding machine which comprises a rack, a third motor, a first motor, a first rolling-up spindle, a transmission wheel, a driving wheel, a second motor, a rolling straight roller and a track wheel, wherein the rack is fixedly connected with the track wheel, the third motor is fixedly connected with the track wheel, the rack is in rotary connection with the first rolling-up spindle, the first motor is in rotary connection with the transmission wheel by a belt, the transmission wheel is in rotary connection with the driving wheel by the belt, the second motor is fixedly connected to the right side of the rack, and the rolling straight roller is in rotary connection with the right side of the rack. According to the invention, a link of heavy manpower carrying is eliminated, and the worker carrying time is released to control operation of the next working position of the winding machine, so that winding of cloth is relatively quick and efficient.

Owner:QINGDAO BEIDOUXINGYUN COMM TECH CO LTD

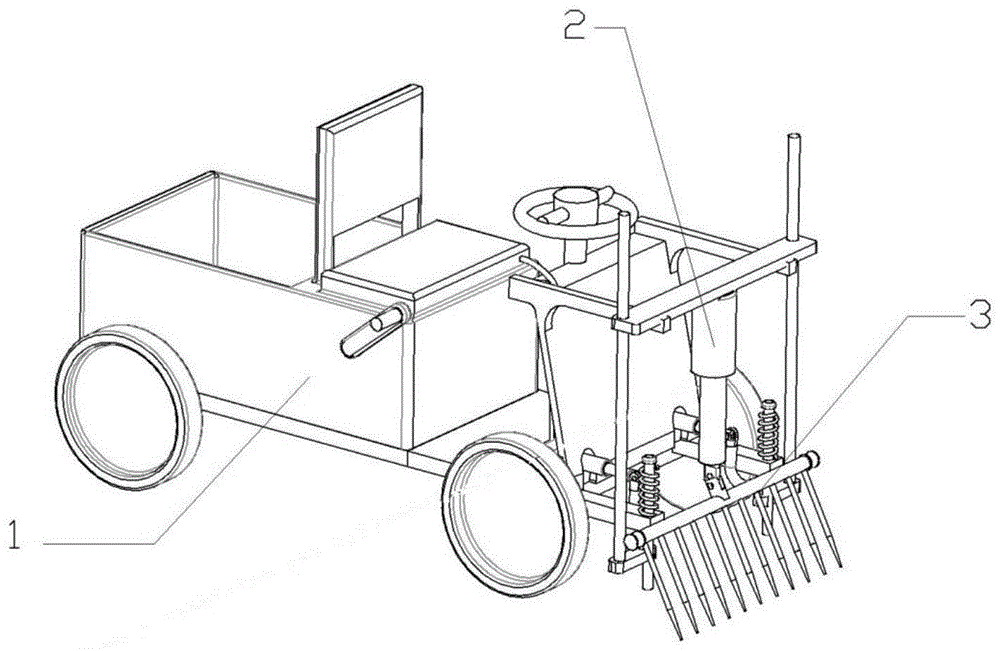

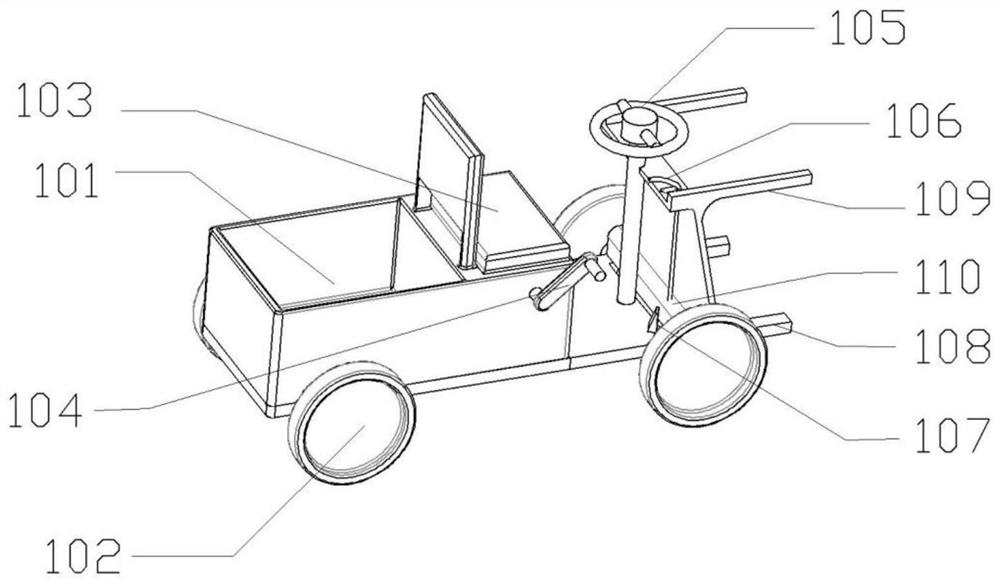

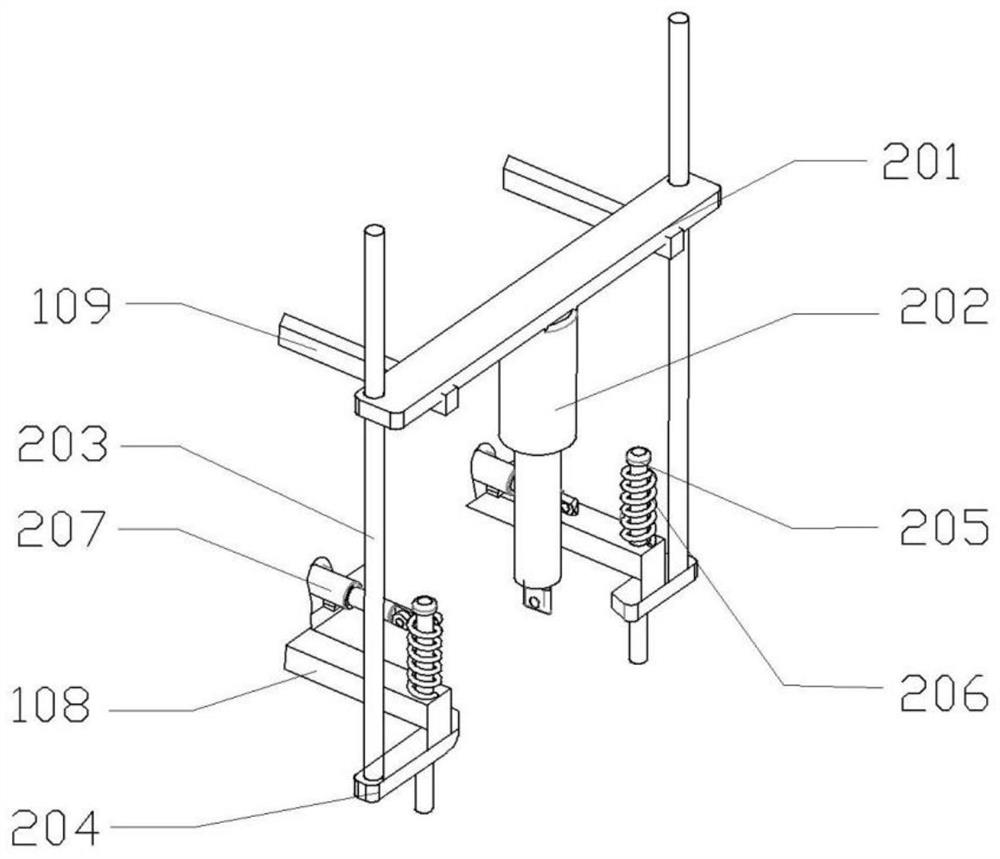

Agricultural motorized extractor of bergamot yam

InactiveCN111602498AOvercoming the disadvantages of miningReduce laborDiggersAgricultural scienceAgricultural engineering

The invention relates to the technical field of agriculture, mainly to an agricultural motorized extractor of bergamot yam. The agricultural motorized extractor of bergamot yam includes a trolley assembly with a power mechanism, a hydraulic assembly which is provided with a lifting function and installed on the trolley assembly and an excavating rake which is installed on the trolley assembly andhydraulic assembly. The invention provides the agricultural motorized extractor of bergamot yam. The hydraulic assembly is installed on a trolley so as to drive the excavating rake to get into the soil and get out of the soil so that yam excavation is completed, and soil can be shaken off through matched use of the hydraulic assembly, so that the excavated yam is clean and tidy, and the shortcomings of traditional yam excavation is overcome; and on the one hand, the amount of labor of laborers can be reduced so that the efficiency of yam excavation by the laborers can be improved greatly, andon the other hand, the operating cost is saved to a large extent, so that the work enthusiasm of the farmers is improved, and existing agricultural tools are innovated.

Owner:黄冈重远坚巨农业科技有限公司

Efficient paint spraying equipment for wooden door processing and surface paint spraying technology

InactiveCN113713983ATo achieve the purpose of automatic paintingUniform paint jobLiquid spraying apparatusStructural engineeringIndustrial engineering

The invention discloses efficient paint spraying equipment for wooden door processing and a surface paint spraying technology. The efficient paint spraying equipment comprises guide rail seats, guide rail baffles and guide rails are arranged at the upper ends of the guide rail seats, a paint spraying frame is arranged on the two guide rails, an operation panel is arranged on one side of the paint spraying frame, a liquid crystal screen, a power switch and setting buttons are arranged on the front side of the operation panel, the other side of the paint spraying frame is connected with a conveying pipe, a pressurizing paint bucket and a rolling crawler belt are arranged below the conveying pipe, a paint spraying head is arranged below the inner side of the paint spraying frame, a supporting seat, a supporting seat sliding block and a supporting seat guide rail device are arranged between the guide rail seats, a supporting seat guide rail baffle is arranged at the end of the supporting seat guide rail device, a wooden door limiting groove and a wooden door are arranged above the supporting seat, and fastening devices are arranged on the sides of the upper ends of the guide rail seats. Through the guide rails, the guide rail seats, the pressurizing paint bucket, the paint spraying head, the supporting seat guide rail device, the wooden door limiting groove and the like, conventional paint spraying equipment can have the functions of automatic paint spraying, automatic feeding, wooden door limiting and fixing and the like.

Owner:江山市丰泽木业有限公司 +1

Printing roller coding device

The invention discloses a printing roller coding device. The printing roller coding device comprises a machine frame. The machine frame comprises a base plate, a supporting rod and guiding rods, wherein the supporting rod and the guiding rods are vertically arranged on the base plate. Magnetic air cylinders which can move up and down are installed on the guiding rods and connected with a coding machine. Locking mechanisms located below the magnetic air cylinders are installed on the guiding rods. Each locking mechanism comprises an annular plate matched with the corresponding guiding rod. A gap is reserved between the two ends of each annular plate. The two ends of each annular plate extend outwards to form installation plates. One installation plate of each annular plate is connected with the corresponding air cylinder. A piston rod of each air cylinder penetrates through the two corresponding installation plates, and a nut is installed at the tail end of the piston rod of each air cylinder. An adjustment plate used for adjusting the position of a printing roller is connected to the base plate.

Owner:HESHAN SEIKO PLATEMAKING CO LTD

Full-automatic contact lens cleaning device

ActiveCN108144904AAvoid shakingFlexible installationCleaning using liquidsContact lens cleaning devicePower output

The invention discloses a full-automatic contact lens cleaning device and belongs to the field of contact lens cleaning equipment. The full-automatic contact lens cleaning device is characterized in that the full-automatic contact lens cleaning device comprises a base (1), a lens rotary power device, a lifting rotary device and a cleaning device body; the vertically arranged cleaning device body is mounted on one side of the top of the base (1); the cleaning device body is internally provided with a rotationally mounted meshy lens box (15); the lifting rotary device is mounted on the other side of the top of the cleaning device body; one end of the lens rotary power device is rotationally mounted at the top of the lifting rotary device; and the power output end of the lens rotary power device makes contact with and is connected with the top of the meshy lens box (15) through a transmission mechanism. The mode that the cleaning device body is fixed and lenses are rotated forwards and reversely is adopted, thus, care solutions create vortex, and the lenses can make contact with the care solutions more thoroughly and completely; and through rotary power provided by the power device, the trouble of manual scrubbing is avoided, the risk of lens breakage is avoided, and the lenses can be cleaned rapidly in a short time.

Owner:郑见财

Semi-automatic plate embossing plate

The invention discloses a semi-automatic plate embossing plate. The semi-automatic plate embossing plate comprises a rack. A bearing device is arranged on the rack. The two sides of the bearing device are provided with embossing devices. Each embossing device comprises mechanical arm assemblies arranged on the two sides of the bearing device and an embossing assembly arranged between the two mechanical arm assemblies. A discharge bin is arranged on one side of the bearing device and comprises a hollow first bin body arranged on the rack. Third slide rails are arranged on the two sides of the first bin body respectively and provided with a first box body capable of moving vertically along with the third slide rails. The first box body is horizontally provided with a plurality of first isolation layers used for containing a plate. The other side, provided with the bearing device, of the rack is provided with a groove in which a material collecting assembly is arranged. One side of the first bin body and one side of a second bin body are each provided with a driving device connected with the first box body and a second box body. The driving devices can control the first box body and the second box body to move upwards or downwards.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

Discharging device based on battery cell primary packaging system

InactiveCN109818037AEliminate manual handlingFinal product manufactureSecondary cells manufactureDrive wheelDrive motor

The invention relates to a discharging device based on a battery cell primary packaging system. The device comprises a rack, a driving wheel and a driven wheel are arranged at the two ends of the rackrespectively, the driving wheel and the driven wheel are connected through a conveying belt, a supporting plate is fixed to the surface of the conveying belt, a jig is fixed to the supporting plate,a photoelectric sensor is arranged on the jig, and an original point induction photoelectric device is arranged on one side of the driving wheel. The battery cells are conveyed to the material receiving end through the conveying belt, manual carrying is avoided, during collection, the mechanism provides multiple stations, material receiving can be conducted at the same time, and the conveying speed of the conveying belt is changed by adjusting the rotating speed of the driving motor so as to meet the conveying speed requirement during collection operation of the number of people.

Owner:惠州市至元智能装备有限公司

Tubular pile steel bar framework reinforcing and bundling device

ActiveCN112392040AEasy to fixConvenient welding operationPhotovoltaic energy generationBulkheads/pilesElectric machineryRebar

The invention discloses a tubular pile steel bar framework reinforcing and bundling device, and relates to the technical field of tubular pile steel bar bundling. The tubular pile steel bar frameworkreinforcing and bundling device comprises a base; a sliding groove is formed in the top of the base; a fixed base is arranged at the top of the base; a motor is installed at the top of the fixed base;a fixed disc is arranged on one side of the motor; a limiting disc is fixed in the fixed disc; a plurality of sets of limiting holes are formed in the outer side of the limiting disc; and a connecting shaft is fixed to one side of the limiting disc. By means of correspondence of limiting grooves and steel bar rings and correspondence of upper notches in the steel bar rings and the limiting holes,steel bars can be placed in the upper notches, the limiting disc and the steel bar rings are driven to rotate through rotation of the fixed disc, the steel bars can be conveniently placed on the surfaces of the steel bar rings, and then the steel bars are welded at the positions of the upper notches; and the strength of a steel bar framework is improved through the steel bar rings, the steel bars, first connecting steel bars, second connecting steel bars, reinforcing steel bars, upper reinforcing steel bar rings and lower reinforcing steel bar rings.

Owner:富强科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com