Braided fabric bagged crude tobacco packer carrying wire rope robot system

A robot system and robot technology, which is applied in the stacking of objects, de-stacking of objects, and program-controlled manipulators, etc., can solve the problems of large floor space, many equipment, and poor system capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

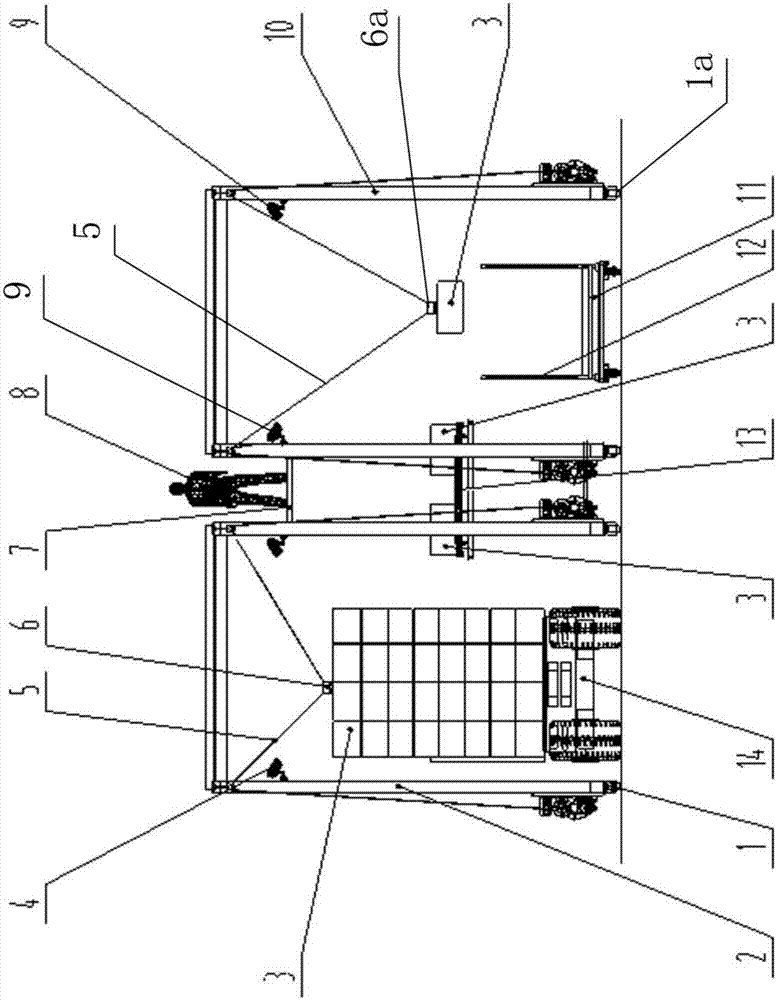

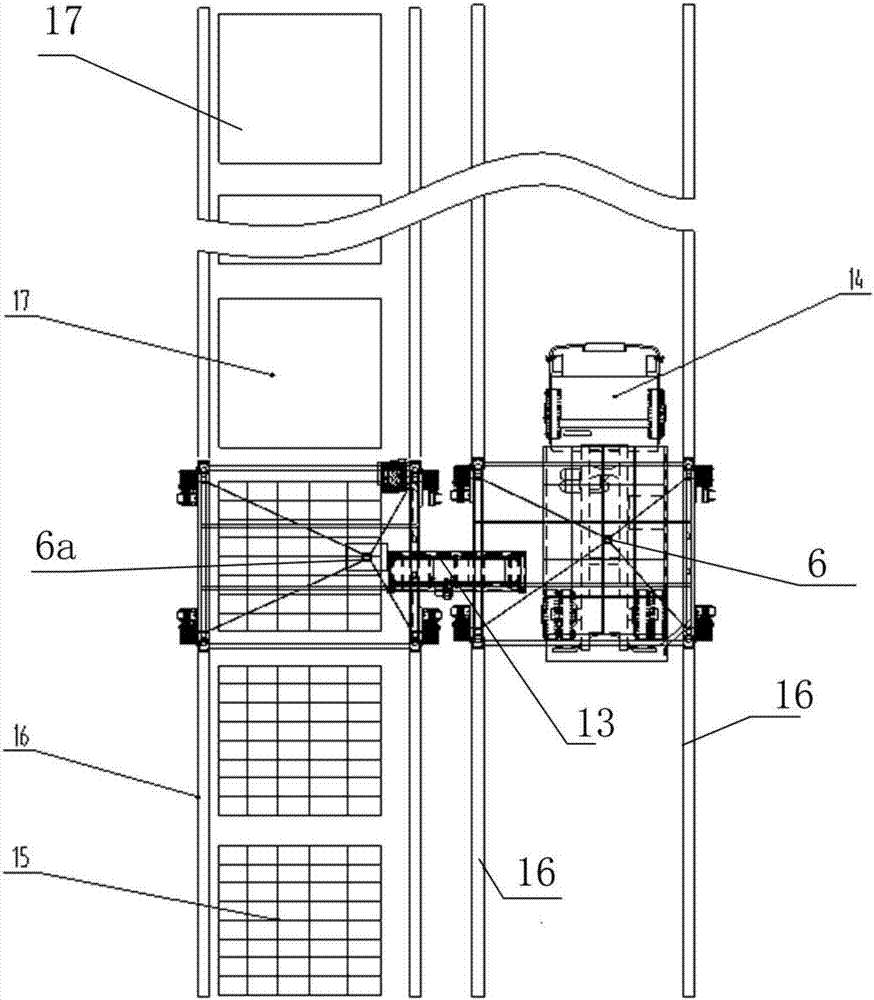

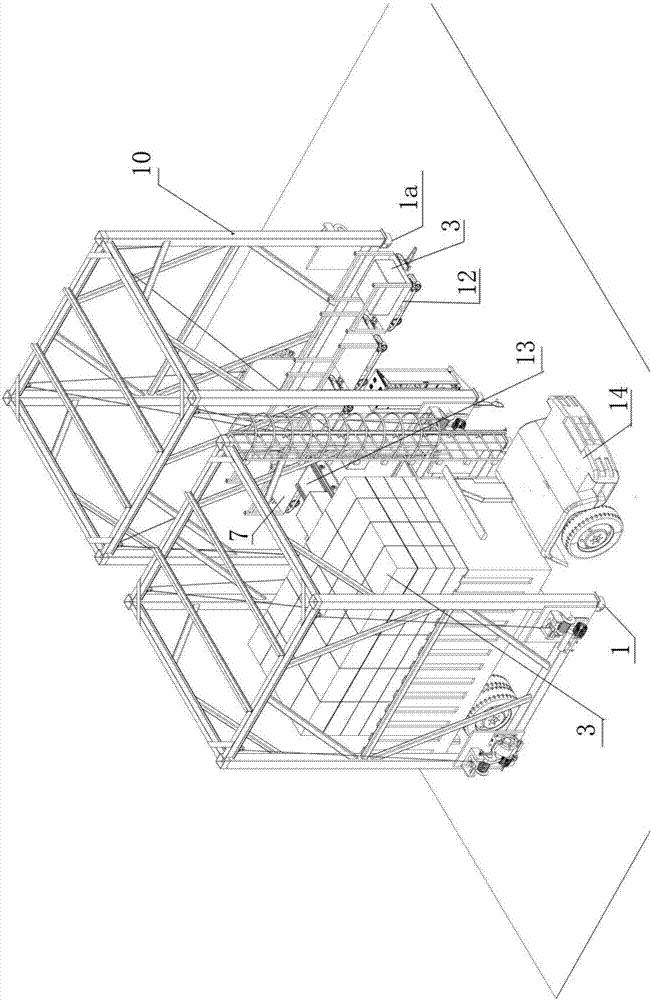

[0026] See figure 1 , The steel cable robot system for handling the original cigarette packs packed in bags according to the present invention mainly includes a first running device 1, a second running device 1a, a first steel cable robot frame 2, a first vision system device 4, and a transition conveying device 13. The second cable robot frame 10, the second vision system device 9, the first grabbing device 6, the second grabbing device 6a, and the artificial platform 7; wherein, the first / second cable robot frame 2, 10 The running device (at the bottom of the first / second wire rope robot frame) is used as a support for other devices; the first / second wire rope machine frame is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com